PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

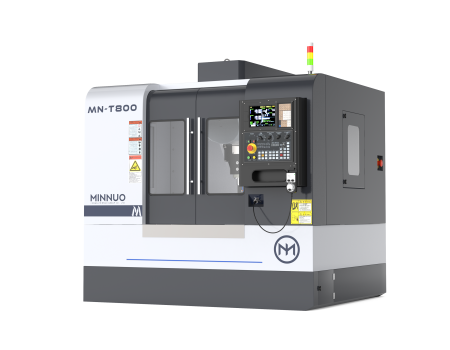

High-Performance High-Speed Drilling, Milling And Tapping Centre MN-T800

The MN-T800 is a high-performance high-speed drilling, milling and tapping centre with mechatronic design and stylish appearance, capable of precision cutting. With high rigidity, stability and reliability, the machine is suitable for machining medium-sized complex parts such as cases, plates, discs and shell parts. It is widely used in industries such as 3C products, IT equipment, optical instruments, medical equipment and aluminium alloy products.

- Bench size (length and width): 900×400mm

- Triaxial stroke (X / Y / Z): 800/400/300

- Maximum carrying capacity: 300kg

- Main shaft speed: 20000rpm

Name | Unit | Parameter | |

Range of work | Triaxial stroke (X / Y / Z) | mm | 800/400/300 |

The distance from the main nose to the working top | mm | 150~450 | |

Workingbench | Bench size (length and width) | mm | 900×400 |

Maximum carrying capacity | kg | 300 | |

T-type groove (slot number, slot width spacing) |

| 3×14×120 | |

Spindle | Spindle diameter / cone hole | mm | φ100/BT30 |

main shaft speed | rpm | 20000 | |

Power of spindle motor | kW | 3.7/5.5 | |

Speed | Fast moving speed (X / Y / Z axis) | m/min | 48/48/48 |

Cut into give speed | m/min | 10/10/10 | |

Tool magazine | Number of knives | grasp | 21 |

Tool maximum diameter / length / weight of |

| φ60mm/200mm/3kg | |

Maximum diameter (full / adjacent) | mm | 60/80 | |

Tool exchange time (knife-knife) | S | 1.3 | |

Machine tool accuracy | Positioning accuracy (X / Y / Z) | mm | 0.008 |

Repeat positioning accuracy (X / Y / Z) | mm | 0.005 | |

Else | Specification of straight-line rolling guide gauge (X / Y / Z) | mm | 30/30/35 |

Ball screw specification (X / Y / Z) | mm | 32/32/32 | |

Servo motor specification (X / Y / Z) | N.m | 9/9/22.5 | |

Gas source / air pressure |

| 280L/min 6~8bar | |

Total electrical capacity of the machine tool | KVA | 15 | |

Machine tool external type size (XYZ) | mm | 2200×2600×2700 | |

Machine tool weight (about) | kg | 3500 | |

Features

- CNC Drilling and Tapping Center MN-T800 is made of high quality cast iron material, combined with integrated mechanism and herringbone structure design to ensure superior rigidity and stability.

- Equipped with internal-circulation oil-cooled spindle and international brand bearings, as well as key drive components, it enhances the life, efficiency, precision and stability of cutting.

- By equipping heavy-duty linear roller guideways and double-layer enclosed hydrostatic table in X, Y and Z axes, the loading capacity, efficiency, precision and surface finish quality are greatly improved.

Applications

- High-performance high-speed MN-T800 is suitable for the production and processing of small-lot, multi-species or single-piece high-volume production of small and medium-sized plates, sheets, cases, shells, molds and other various parts.

- It is widely used in almost all industries such as aerospace, shipbuilding, automobile, machine tool, light industry, textile, electronics, general machinery, engineering machinery and so on.

| Order number | Name | Quantity | Remarks |

| 1 | The Mitsubishi M80B CNC system | 1 | Fanuc/Siemens |

| 2 | Hand-held operating unit | 1 | |

| 3 | Arm knife library | 1 | 21 Tools |

| 4 | Automatic lubrication system | 1 | |

| 5 | Tri coloured lantern | 1 | |

| 6 | Spindle blowing device | 1 | |

| 7 | Air curtain protection | 1 | |

| 8 | headlamp | 1 | |

| 9 | Random attachment | 1 | |

| 10 | Random complete set of standard technical documents | 1 |

In order to meet different market needs, we provide modular, customised solutions, the system uses the Mitsubishi CNC controller can also be upgraded to Fanuc, Siemens, can be any 4-axis combination of machining, there is a need to contact us.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com