PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

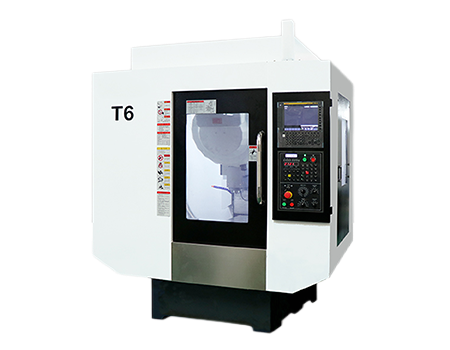

High Speed Drilling & Tapping Machining Centre TC-540

The drill tap machining centre TC-540 is a machine with a new design method optimised by Finite Element Analysis (FEM). It features a high speed spindle and a precision transmission system to ensure accurate and efficient machining. The machine has a stable structure, friendly operation interface, and supports automatic tool change, which is suitable for diversified machining needs. It is suitable for small precision parts machining in automotive, electronics and other industries.

- Bench size (length and width): 650×400mm

- Triaxial stroke (X / Y / Z): 500/400/300

- Maximum carrying capacity: 300kg

- Main shaft speed: 20000rpm

Name | Unit | Parameter | |

Range of work | Triaxial stroke (X / Y / Z) | mm | 500/400/300 |

The distance from the spindle center line to the column guide rail surface | mm | 466 | |

The distance from the main nose to the working top | mm | 150~450 | |

Workingbench | Bench size (length and width) | mm | 650×400 |

Maximum carrying capacity | kg | 300 | |

T-type groove (slot number, slot width spacing) |

| 3×14×121 | |

principal axis | main shaft speed | rpm | 20000 |

taper hole of spindle |

| BT30 | |

Power of spindle motor | kW | 3.7/5.5 | |

Speed | Fast moving speed (X / Y / Z axis) | m/min | 48/48/48 |

Cut into give speed | m/min | 10/10/10 | |

Tool magazine | Number of knives | grasp | 21 |

Tool maximum diameter / length / weight of |

| φ 60mm/200mm/3kg | |

Maximum diameter (full / adjacent) | mm | 60/80 | |

Machine tool accuracy | Positioning accuracy (X / Y / Z) | mm | 0.008 |

Repeat positioning accuracy (X / Y / Z) | mm | 0.005 | |

Else | Gas source / air pressure |

| 280L/min 6~8bar |

Total electrical capacity of the machine tool | KVA | 15 | |

Water tank volume | L | 160 | |

Machine Exsize (XYZ) | mm | 1880×2600×2700 | |

Machine tool weight (approx.) | kg | 3200 | |

Features

The TC540 is a high-speed drilling and tapping centre with a mechatronic design that offers stylish looks and precision cutting capabilities. The machine is optimally designed through finite element analysis to provide high rigidity and stability, and is equipped with a high-speed spindle and three-axis linear guideways to ensure fast and accurate machining performance.

- Spindle and motor direct connection design eliminates drive noise, backlash, belt or gear vibration. The motor output directly drives the spindle at speeds up to 20,000 rpm, providing high quality thread tapping results and surface finish. The main motor with low inertia motor can achieve rapid acceleration from 0 to 20,000 rpm in just 1 second, avoiding stripping during high-speed tapping changeover.

- Machine base, table, column, beam, saddle, spindle box and other components are resin sand casting HT300 strength ductile cast iron, after the second annealing to eliminate casting and processing stress, to ensure high rigidity, stability and quality.

- The T540 machine adopts imported ball screws and linear guide rails, in order to ensure the rigidity and durability of the machine, improve the load capacity and extend the service life of the machine.

Applications

- The TC-540 drilling and tapping machining centre is designed for small and precise metal parts with its excellent high rigidity, fast response and high efficiency, and excels in mass production of multi-hole machining, high-speed drilling, milling and tapping.

- This machine excels in industries such as 3C, mobile devices, automotive parts, precision instruments, electronics and medical, making it an ideal choice for machining small and light metal parts.

| Order number | Name | Quantity | Remarks |

| 1 | The Mitsubishi M80B CNC system | 1 | Fanuc/Siemens |

| 2 | Hand-held operating unit | 1 | |

| 3 | Arm knife library | 1 | 21 Tools |

| 4 | Automatic lubrication system | 1 | |

| 5 | Tri coloured lantern | 1 | |

| 6 | Spindle blowing device | 1 | |

| 7 | Air curtain protection | 1 | |

| 8 | headlamp | 1 | |

| 9 | Random attachment | 1 | |

| 10 | Random complete set of standard technical documents | 1 |

If you want to customize the configuration of high speed drilling & tapping machining centre TC-540, you can connect with our engineers and do one-on-one communication for a win-win situation.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com