PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

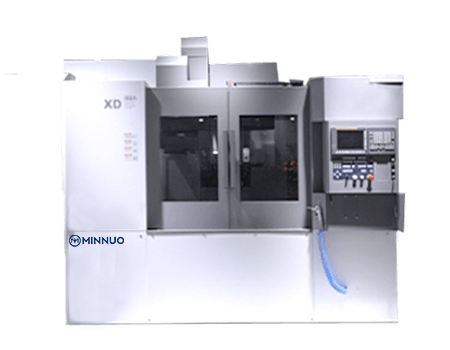

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

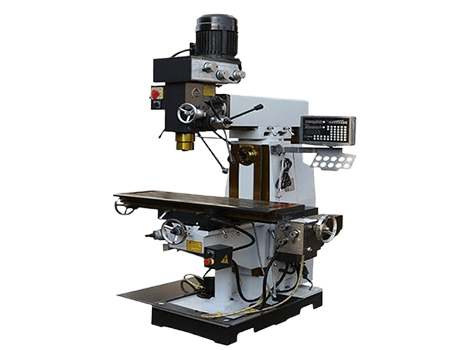

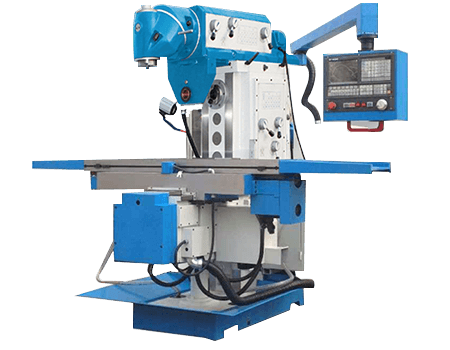

Economical Conventional Ram Milling Machine XL6230 Series

Conventional ram milling machine XL6230 series is an economical milling machine, 3-axis guideways are quenched, the bonding surface is scraped by manual scraping process, manual feed, a servo motor to control the table three-way feed, digital ruler is optional, can also be upgraded to CNC system.

- Table size: 1370×300

- T-slots(NO./width/pitch): 3/14/80mm

- Max table travel-X/Y/Z: 1000/380/400mm

Features

XL6230 ram milling machine, can realize vertical and horizontal dual-use, when the head rotary can be horizontal milling, and the worktable can be optional for rotary table, can be ± 45 ° rotary.

- Universal rotary head can be manually rotated to any angle, vertical and horizontal, to meet the processing of various angles, the spindle is IS040 type, the use of flexible.

- All tables and guide surfaces are quenched with high-frequency quenching to improve the hardness of guide rails for good wear resistance and durability.

- Adopting gear transmission with 11 levels of speed change, wide range of speed change to meet the requirements of different material processing.

- The worktable area is 1270x300mm, capable of supporting 300kg of weight, the X-square stroke is extended to 720mm, and the worktable surface is hardened.

Applications

- The ram milling machine XL6230 is widely used in mold making, machining, automotive industry and aerospace industry, etc. Its high rigidity structure and flexible operation can efficiently and accurately process all kinds of complex parts, meet the user’s needs for high precision and versatility, and significantly improve production efficiency and product quality.

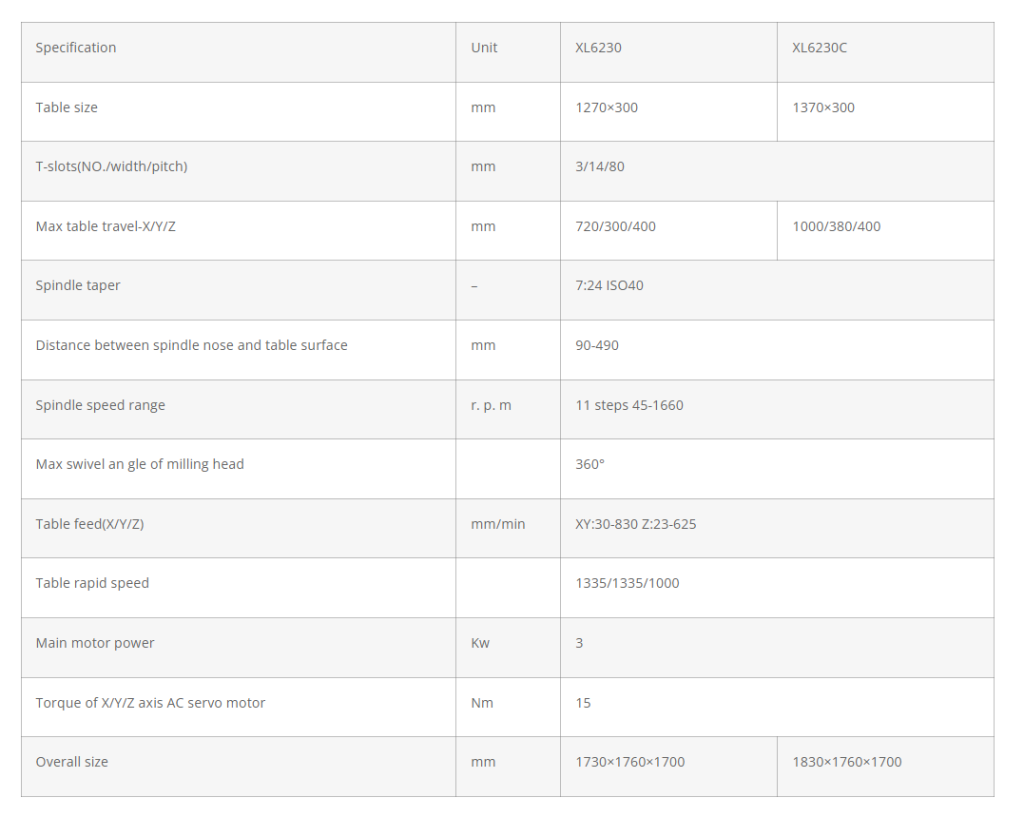

Specification | Unit | XL6230 | XL6230C |

Table size | mm | 1270×300 | 1370×300 |

T-slots(NO./width/pitch) | mm | 3/14/80 | |

Max table travel-X/Y/Z | mm | 720/300/400 | 1000/380/400 |

Spindle taper | – | 7:24 ISO40 | |

Distance between spindle nose and table surface | mm | 90-490 | |

Spindle speed range | r. p. m | 11 steps 45-1660 | |

Max swivel an gle of milling head | 360° | ||

Table feed(X/Y/Z) | mm/min | XY:30-830 Z:23-625 | |

Table rapid speed | 1335/1335/1000 | ||

Main motor power | Kw | 3 | |

Torque of X/Y/Z axis AC servo motor | Nm | 15 | |

Overall size | mm | 1730×1760×1700 | 1830×1760×1700 |

Features

XL6230 ram milling machine, can realize vertical and horizontal dual-use, when the head rotary can be horizontal milling, and the worktable can be optional for rotary table, can be ± 45 ° rotary.

- Universal rotary head can be manually rotated to any angle, vertical and horizontal, to meet the processing of various angles, the spindle is IS040 type, the use of flexible.

- All tables and guide surfaces are quenched with high-frequency quenching to improve the hardness of guide rails for good wear resistance and durability.

- Adopting gear transmission with 11 levels of speed change, wide range of speed change to meet the requirements of different material processing.

- The worktable area is 1270x300mm, capable of supporting 300kg of weight, the X-square stroke is extended to 720mm, and the worktable surface is hardened.

Applications

- The ram milling machine XL6230 is widely used in mold making, machining, automotive industry and aerospace industry, etc. Its high rigidity structure and flexible operation can efficiently and accurately process all kinds of complex parts, meet the user’s needs for high precision and versatility, and significantly improve production efficiency and product quality.

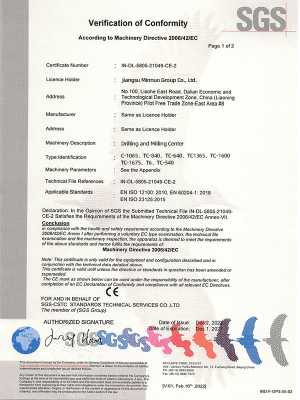

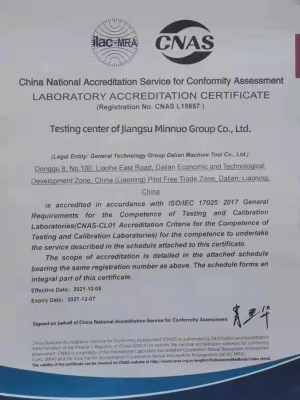

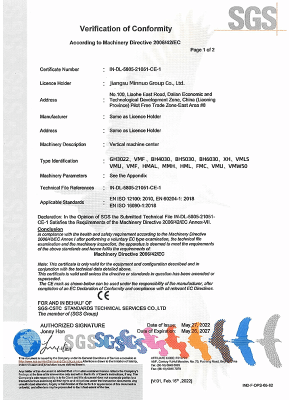

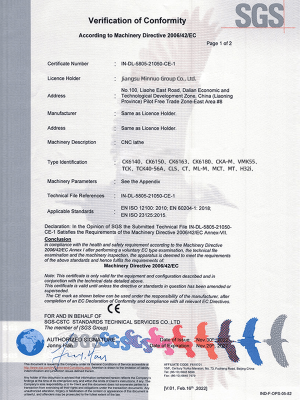

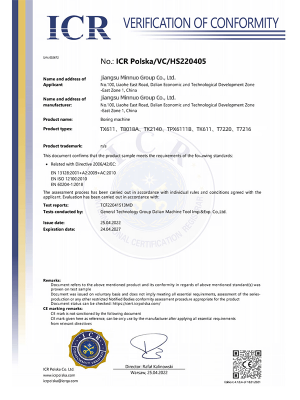

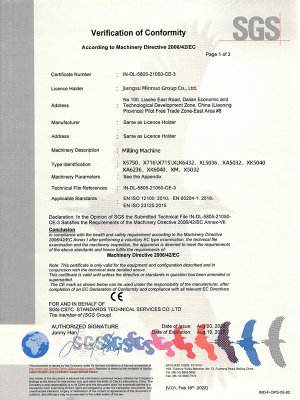

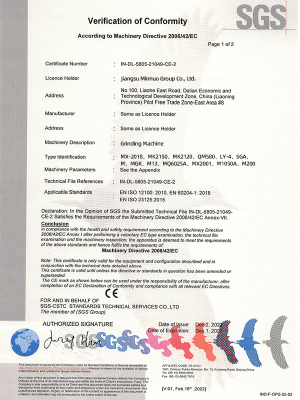

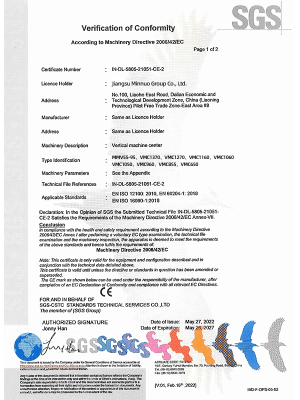

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com