PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

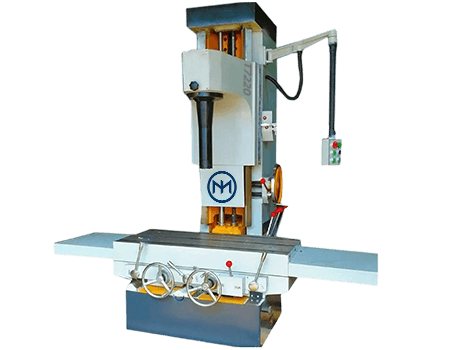

Vertical Fine Boring Machine T7220/T7216 Series

Vertical fine boring machine T7220/T7216 is a high-precision machine tool specially designed for the finishing of cylinder block holes, with high rigidity, high stability and fast response, widely used in automotive, internal combustion engine and other industries for the processing of precision holes such as engine block holes and cylinder liner holes, which ensures that the roundness of processed holes is within 5 microns, and the surface roughness is up to Ra0.63~0.08 microns, which significantly improves the production efficiency and product quality.

- Boring range: Φ35-200mm

- Table size (L×W): 1200×500mm

- Table longitudinal travel: 900mm

- Table lateral travel: 100mm

Features

- Fineboring machine T7220/T716 series has a vertical bed, slide and spindle that is moving up and down along the bed guideway; before the bed there is a fixed workpiece can be moved in the XY direction of the worktable. The machine tool consists of the following components: bed, slide, gearbox, spindle, table, base, operating mechanism group creation.

- The spindle motor of this machine tool adopts frequency conversion segment infinitely variable speed regulation, XYZ movement can be optional digital display system display.

- The positioning device of the cylinder boring machine is characterized in that it comprises a positioning seat, a positioning top core and at least three identical positioning columns, said positioning seat comprises a support seat and a positioning sleeve, the side wall of the positioning sleeve is provided with at least three through holes to cooperate with the positioning columns, and each of the through holes is perpendicular to the center line of the positioning sleeve, and the said positioning top core is in the shape of a nail, with a nail cap provided at the fixed end, and the working end of the core is a cone, and the cone is resisted to the inner end of each of the positioning columns. the inner end of each positioning column.

- The internal chip removal method or external chip removal method is adopted for drilling.

- Machine bed rigidity, spindle speed range, feeding system driven by AC servo motor, can adapt to the needs of deep hole machining process, the oil granting device fastening and workpiece top tightening using hydraulic devices, instrument display.

Applications

- Vertical fine boring machine T7216、T7220 series products are designed for high speed and high efficiency equipment. Mainly used for automobile, motorcycle engine cylinder holes and tractor, diesel engine, freezer, air compressor cylinder block, etc. Manufacturing and repair, but also can be used for other requirements of precision boring processing.

specifications | Unit | T7216 | T7220 | |

Boring range | mm | Φ35-165 | Φ35-200 | |

Slider movement | mm | 550 | 710 | |

Distance from spindle centerline to slide | mm | ≮315 | ≮315 | |

Handwheel one turn slide frame movement | mm | 4.23 | 4.23 | |

Spindle speed steps and range (8 steps) | At low motor speed | rpm | 70,100,280, 400 | 70,100,280, 400 |

At high motor speed |

| 140,200,560, 860 | 140,200,560, 860 | |

Spindle steps per revolution and range (4 steps) | mm/rev | 0.05,0.08, 0.125,0.20 | 0.05,0.08, 0.125,0.20 | |

Rapid traverse speed | mm/min | 15,793,217 | 15,793,217 | |

Table size (L×W) | mm | 1200×500 | 1200×500 | |

Table longitudinal travel | mm | 700 | 900 | |

Table lateral travel | mm | 100 | 100 | |

Boring accuracy | mm | 0.005 | 0.005 | |

Ellipticity/Cylindricality/Surface roughness | mm | 0.005/0.01/300▽1.6 | 0.005/0.01/300▽1.6 | |

Auxiliary drive |

| YD112M-8/4 1.5/2.4KW, 700/1400rpm | YD112M-8/4 1.5/2.4KW, 700/1400rpm | |

Overall Dimension(L×W×H) | mm | 1610×2100×2090 | 1610×2100×2250 | |

Net weight | kg | 4000 | 4600 | |

Random spindle |

| Φ75 | Φ75 | |

Processing range | mm | Φ76-Φ115 | Φ76-Φ115 | |

Spindle | mm | Φ35,Φ50, Φ110 | Φ50,Φ110, Φ130 | |

Φ35 spindle range | mm | Φ36-Φ50 | \ | |

Φ50 spindle range | mm | Φ51-Φ75 | Φ51-Φ75 | |

Φ110 spindle range | mm | Φ111-Φ165 | Φ111-Φ165 | |

Φ130 spindle range | mm | \ | Φ131-Φ200 | |

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com