PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

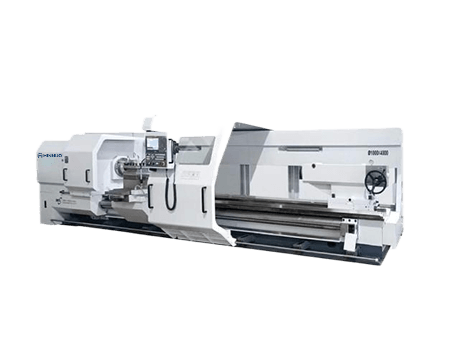

Large Flat Bed CNC Lathe CKA-M Series

CNC lathe CKA-M series is a large-scale CNC horizontal lathe with vertical (Z) and horizontal (X) coordinates control. It is capable of automatically completing the cutting of internal and external cylindrical surfaces, conical surfaces, arc surfaces, end surfaces, grooving, chamfering and other processes on large shafts and disks, as well as turning metric straight threads, end threads, imperial straight threads and taper threads. The machine tool adopts FANUC, Siemens and other well-known companies at home and abroad CNC system, the workpiece can be repeated cycle processing. Suitable for multi-species, high-volume production, especially for complex, high-precision parts can show superiority.

- Max. swing diameter over bed: φ1000~φ1250mm

- Max. swing diameter over cross slide: φ630~φ880mm

- Max. workpiece length: 750~1500mm: 1500/2000/3000/4000/5000/6000mm

Features

- The machine tool adopts the layout of traditional horizontal lathe, and the overall design is well sealed and conforms to the safety standards. The main basic parts such as bed, spindle box, bed saddle and tailstock are all made of resin sand casting, and the stability of the machine tool is good.

- The bed, bed saddle, screw, bracket and other parts related to precision are carefully optimized for structure and machining precision, and assembly control measures are added to improve the machining precision of the machine tool and ensure the consistency, stability and reliability of workpiece processing.

- The numerical control system of the machine tool adopts the products of international famous manufacturers to ensure the high reliability of the machine tool.

- Machine tool adopts electromechanical integration design, the overall layout is compact and reasonable, easy to operate and maintain.

- The machine tool adopts modular design, which can be configured differently according to the user’s needs (such as system configuration), and the design flexibility can meet the various needs of machining different types of parts.

Applications

- Large flat-bed CNC lathe CKA-M series can automatically complete the cutting of internal and external cylindrical surfaces, conical surfaces, arc surfaces, end surfaces, grooving, chamfering, etc. of large shafts and disk parts, as well as a variety of turning processes such as metric straight threads, end threads, imperial straight threads, taper threads and so on.

| Specification | Unit | CKA61100M | CKA61125M |

| Max. swing diameter over bed | mm | φ1000 | φ1250 |

| Max. swing diameter over cross slide | mm | φ630 | φ880 |

| Max. workpiece length | mm | 1500/2000/3000/4000/5000/6000 | |

| Max. cutting length | mm | 1400/1900/2900/3900/4900/5900 | |

| Max. turning diameter | mm | φ1000 | φ1250 |

| Spindle center height | mm | 500 | 625 |

| Main motor power (Servo motor) | kw | 22/26(FANUC) | |

| Chuck size | mm | φ1000 | φ1250 |

| Spindle bore | mm | φ130 | |

| Taper of spindle bore | Front end φ140mm 1:20 | ||

| Type of spindle nose | A₂-15 | ||

| Spindle speed ranges | r/min | 2~500<; (L 2~87/M5~201/H 11~500) | |

| Tailstock quill diameter | mm | φ200 | |

| Tailstock quill travel | mm | 300 | |

| Tailstock quill taper | MT. NO.6 | ||

| Max. travel of X-axis | mm | 520 | 640 |

| Max. travel of Z-axis | mm | 1500/2000/3000/4000/5000/6000 | |

| Rapid traverse of X/Z axis | m/min | 6/8 | |

| Tool shank size (Vertical 4-positon) | mm | 40*40 | |

| X/Z axis positioning accuracy | mm | 0.021/0.026(1500/2000) 0.030(3000/4000/5000/6000) | |

| X/Z axis repeatability accuracy | mm | 0.008/0.014(1500/2000) 0.014(2000) | |

| Machine size(L*W*H) | mm | 6320*2300*2000(1500) 6820*2300*2000(2000) 7820*2300*2000(3000) 8820*2300*2000(4000) 9820*2300*2000(5000) 10820*2300*2000(6000) | 6320*2520*2250(1500)6820*2520*2250(2000)7820*2520*2250((3000)8820*2520*2250(4000)9820*2520*2250(5000)10820*2520*2250(6000) |

| Machine weight | kg | 13500/14000/15000/16000/17000/18000 | 14500/15000/16000/17000/18000/19000 |

Standard accessories:

- FANUC 0i-TF(1)PLUS CNC

- Slide guideway

- Manual four-jaw chuck

- Vertical four-station internally cooled tool holder

- Bed saddle drag tailstock (5000, 6000 specifications for motor-driven movement)

- Automatic chip conveyor, cooling pump and water tank

- Automatic centralized lubrication

- Standard tools

- Electrical cabinet heat exchanger

Optional accessories:

- Siemens 828D numerical control system

- Center frame

- Follow tool holder

- Motor-driven moving tailstock (standard for 5000 and 6000 sizes)

- Spindle bearing NSK

- Electric cabinet thermostat

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com