PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

CNC Floor Boring and Milling Machine

CNC face lathe machine CK64 series products are mainly responsible for all kinds of turning work, capable of turning end face, outer circle, inner hole, grooving and other processes of various parts. The spindle of the machine tool adopts a three-support structure, which has good rigidity; the machine tool adopts the lower chip removal method, which is convenient for chip removal. The machine tool also has a separate oil pump for forced lubrication, as well as fast movement, terminal insurance and other functions. The speed, feed and power characteristics are reasonably designed to meet the needs of rough and finish machining of various parts.

- Max.swing diameter over machine bed : 1250/1600/2000/2500/3000mm

- Max.swing diameter over cutting tool carriage: 800/1250/1600/2000/2500mm

- Max.work-piece weight: 2/3T

- Max.work-piece length: 500/750mm

| Specifications | unit | TK6913 | TK6916 | TK6916EUR | TK6920 | TK6926 | TK6913A | TK6916A | TK6920A | ||

| Headstock | Spindle Diameter | mm | ø130 | ø160 | ø160 | ∅200 | ø260 | 130 | 160 | 200 | |

| Spindle Bore Taper | ISO | 50 | 50 | 50 | 60 | 60 | 50 | 50 | 60 | ||

| Spindle Rotating Speed | r/min | 2~1500 | 2~1500 | 2~1500 | 2~1500 | 2~1500 | 2~2000 | 2~2000 | 2~1500 | ||

| Milling Shaft Head Diameter | mm | ∅221.44 | ø250 | ∅250 | 320 | 400 | ∅221.44 | 250 | 320 | ||

| Cross Section of Ram | mm | 380*420 | 480*520 | 450*450 | 480*520 | 620*740 | 380*420 | 480*520 | 480*520 | ||

| Main Motor Power | kw | 30 | 55 | 55 | 75 | 110 | 30 | 55 | 75 | ||

| Machining Area | Travel of Column(X-axis) | mm | 4000+n×1000 | 6000+n×1000 | 6000+n×1000 | 6000+n×1000 | 5000+n×1000 | 4000+n×1000 | 6000+n×1000 | 6000+n×1000 | |

| Vertical Travel of Head Stock(Y-axis) | mm | 2000-3500 | 3000-5000 | 3000-5000 | 3000-5000 | 4000-6000 | 2000-3500 | 3000-5000 | 3000-5000 | ||

| Travel of Spindle(Z-axis) | mm | 1000 | 1200 | 1000 | 1200 | 1600 | 700 | 1200 | 1200 | ||

| Travel of Ram(W-axis) | mm | 1000 | 1200 | 1000 | 1200 | 1600 | 800 | 1200 | 1200 | ||

| Total Travel of Spindle and Ram | mm | 2000 | 2400 | 2000 | 2400 | 3200 | 1500 | 2400 | 2400 | ||

| Feed Rate | Travel Speed of Column (X) | mm/min | 0.5~6000 | 0.5~6000 | 0.5~6000 | 0.5~6000 | 0.5~6000 | 0.5~10000 | 0.5~10000 | 0.5~10000 | |

| Vertical Travel Speed of Headstock(Y) | mm/min | 0.5~6000 | 0.5~6000 | 0.5~6000 | 0.5~6000 | 0.5~6000 | 0.5~10000 | 0.5~10000 | 0.5~10000 | ||

| Travel Speed of Spindle(W) | mm/min | 0.5~4500 | 0.5~4500 | 0.5~4500 | 0.5~4500 | 0.5~4500 | 0.5~7500 | 0.5~7500 | 0.5~7500 | ||

| Travel Speed of Ram (Z) | mm/min | 0.5~4500 | 0.5~4500 | 0.5~4500 | 0.5~4500 | 0.5~4500 | 0.5~7500 | 0.5~7500 | 0.5~7500 | ||

| Tool Magazine(Optional) | Tool Magazine | 40/60 | 40/60 | 40/60 | 40/60 | 40/60 | 40/60 | 40/60 | 40/60 | ||

| Max. Weight of Tool | Kg | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | ||

| Max. ToolDiameter | Occupancy of All Tool Positions | mm | ø125 | ø125 | ∅125 | ø125 | ø125 | ∅125 | ø125 | ø125 | |

| Vacant adjacent Tool Position | mm | ∅250 | ∅250 | ∅250 | ∅250 | ∅250 | ∅250 | ∅250 | ∅250 | ||

| Max. Tool Length | mm | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | ||

| ATC Time | Sec | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | ||

| Control System(Optional) | Fagor/Siemens/Fanuc | ||||||||||

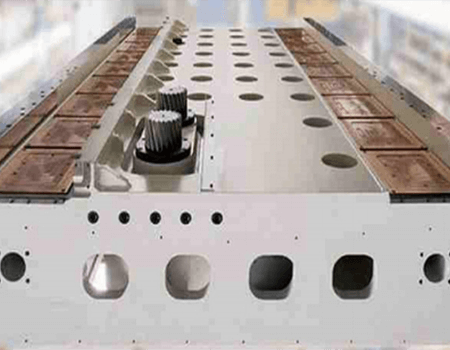

Main Castings

- Machine Bed: The machine bed is built of resin,wood former with reasonable structure and rigidity. It guarantees a sound base and the steadiness of the machine and the stability of column in motion on the bed. There are top quality imported ground hard dent surface racks on the bed.two preload gears co-drive ensures the accuracy of X axis.

Sliding Carriage: Built with top quality castings, resin and wood former,the sliding carriage possesses sufficient intensity. It connects to the machine bed with two wide guide ways. The single guide way serves as main positioning with support from double guide ways to maintain the stability and linearity of column in motion on machine bed.

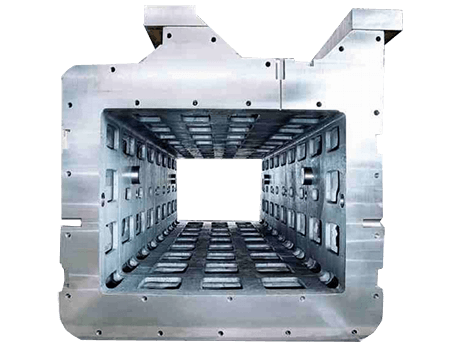

Column: Made of high quality castings, resin and wool former in a double-frame structure, the column is of sufficient rigidity that allows the smooth movement of spindle box vertically. Mosaic type counterweight balance rails are built inside the column to ensure the stability of the counterweight’s vertical movements, thus to ensure the high precision of the machine.

The two around rails in front of the column check the position of spindle box and en sure the steadiness of spindle’ vertical movements. The column is equipped with preload precision double-nut ball screws, and servo motor drives the vertical travels of the spindle box.

Spindle Box: Built with high quality resin, wood former and of box structure.

Machine Control Unit: The operation booth is built with the spindle box, machine’s control unit is built in the booth for easy operation. Rotatable control panel and the handset unit that allows long distance operation makes the operation simple and efficient.

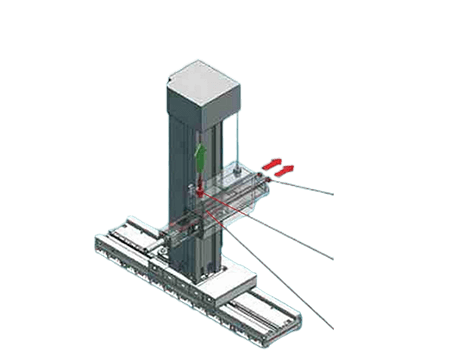

Square Ram: Top of ram is built with hydraulic proportional valve for precision compensation of the horizontal movements of ram, and auto compensation for prevention of droop.

Hydraulic System: There are two hydraulic systems in the machine. The smaller unit is set at the back part cf spindle box and is mainly to control the spindle broach unit and the main transmission gear’s gearshift unit. The bigger hydraulic unit is built in the foundation of the workshop with the machine and supplies all axis with hydrostatic oil and lubricant oil, and supplies spindle with coolant oil.

The machine’s hydraulic oil runs in enclosed structure and flows back to the tank in the big hydraulic unit.

Guideway Protection Cover: Y axis gu de way is built with armor type organ shield, the front end of shield is of metal armor structure to prevent burns resulted from chips, other parts of the shield is of organ type structure that relieves the additional load by the spindle’s vertical travels and for easy maintenance. X axis gu de way is built with steel sliding structure shield that includes the return chutes inside the shield to prevent the ship spilling to the return chutes and causing pollution.

Applications

- CNC Floor Boring and Milling Machine can complete drilling, reaming, boring and other hole processing, grooving, plane and surface milling at one time. It can perform angle milling, turning boring and multi-face machining on workpieces mounted on the rotary table. Using the continuous indexing function of the CNC rotary table, it can continuously carry out the processing of space continuous surface (such as impeller), and the machine tool can also carry out the processing of threading, rigid tapping, etc.; the use of milling cutter’s circumferential milling to realize the boring of large holes, etc.; and the processing of various characteristic holes such as circumferential, box-shaped and polar distribution.

Ram and Compensation System: Built with ductile cast iron QT60-3, and casted with resin and wool former. Large end face surface to ensure strength of ram.Top of ram is equipped with hydraulic pull rods controlled by proportional valve to prevent the droop and deformation of ram.Milling spindle and moving spindle (boring spindle) are built inside the ram.

- Two pull rods are built on top of the ram, the hydraulic cylinder movements are controlled by hydraulic proportional valve.As ram moves forward, the rods are pulled tight under CNC control to eliminate the droop of ram and ensure the precision of ram in extension.

- The electro-hydraulic balance compensation device on spindle box is to eliminate the spindle droop resulted from spindle box’s shift of center of gravity.

- The machine adopts the structure of ram driving spindle box, which means the main transmission reducer is built at the back end of ram and feeds with ram. This structure has improved the spindle’s stability and quality of machining under interrupted conditions, thus to achieve the spindle’s high speed and steady spinning.

Item | Unit | Specification |

Loading | ton | 20、40、60、80、100、140、200、260、320 |

Table size | mm | 1200×1400、1400×1600、1600×1800、1800×2000、 |

V axis linear strokes | mm | 1600、2000、2500、3000(customized) |

B axis rotation degree |

| 360 |

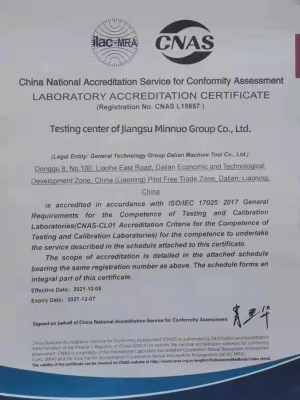

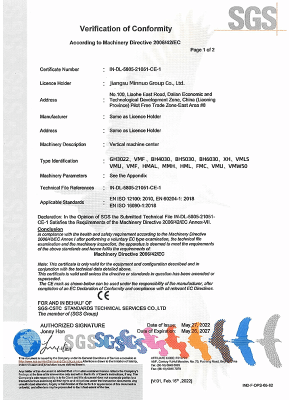

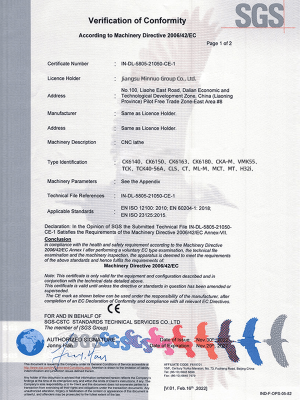

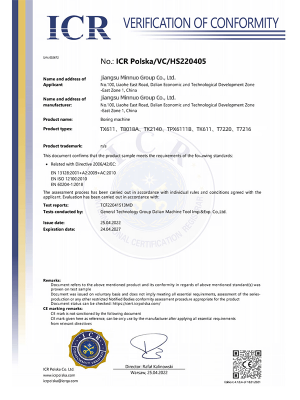

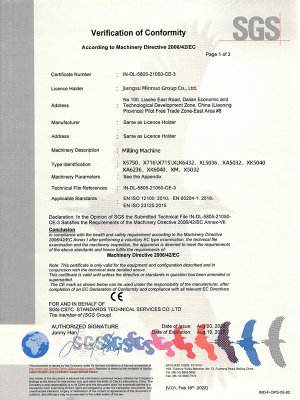

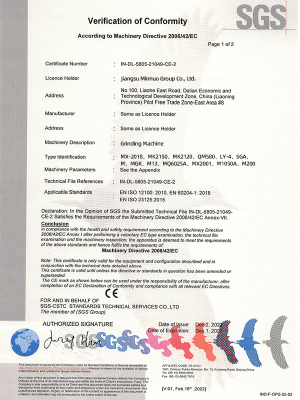

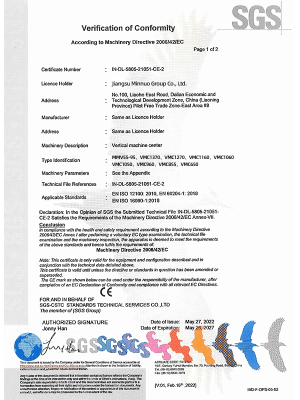

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com