PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

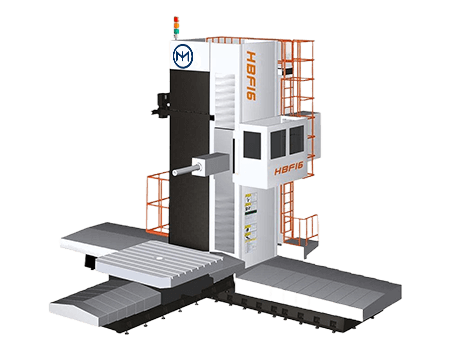

Semi-Automatic Floor Boring Machine TX611 Series

Semi-automatic floor boring machine TX611 is multifunctional, capable of boring, milling, drilling and other processing methods to meet different processing needs. It adopts high-precision guide rail and servo drive system to ensure high precision and stability during machining. With good operation interface and intelligent control system, it simplifies the operation process and improves the working efficiency.

- Spindle diameter: φ110mm

- Spindle box travel: 900mm

- Table working size (L*W): 1130*930mm

Specifications | Unit | TX611 |

Spindle diameter | mm | φ110 |

Spindle taper | MT | 6# |

Spindle speed | (9 step) | 20-460 |

Spindle lift speed | mm/min | 50-720(stepless speed) |

Spindle box travel | mm | 900 |

Spindle axial travel | mm | 400 |

Table longitudinal feed speed | mm/min | (6 step) 6-240 |

Table transverse feed speed | mm/min | (6 step) 6-240 |

Table working size (L*W) | mm | 1130*930 |

Table longitudinal travel | mm | 1400(Without tailstock) |

Table transverse travel | mm | 1200 |

Stroke of flat rotary disk | mm | 165 |

Table load capacity | T | 3 |

Overall dimensions | mm | 3800*2000*2500 |

Net weight | KG | 9000 |

Features

- The main milling head adopts ram-accelerator box combination design to improve the accuracy of the milling head, and the accelerator box adopts two-toothed cone active speed change mechanism to obtain low-speed high torque and high-speed constant power, and can meet the process requirements of roughing and finishing at the same time.

- The high-precision main optical axis combined with bearings ensures high functionality and precision of the main milling head, and the ram milling head is balanced by hydraulic cylinders for smooth movement.

- The three-axis transmission adopts exported high-precision pre-tensioned ball screw or double-bevel rack and pinion backlash-free transmission to ensure transmission accuracy.

- According to user requirements, the use of photoelectric complementary device to complete the semi-closed-loop state reaction force, or the use of grating scale to complete the full closed-loop state feedback.

Applications

- Semi-automatic floor boring and milling machine can meet the processing needs of ultra-large parts in important fields such as flight and aerospace, thermal power generation facilities, buses, etc. High-speed CNC lathes, two-end machining and other commodities are widely used in buses, aerospace, electronics, military and other specialized fields, which affects many small and medium-sized companies in the renovation of their facilities and industrial upgrading.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com