PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

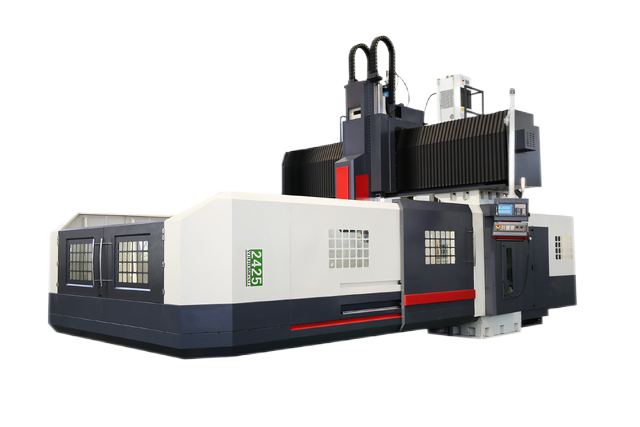

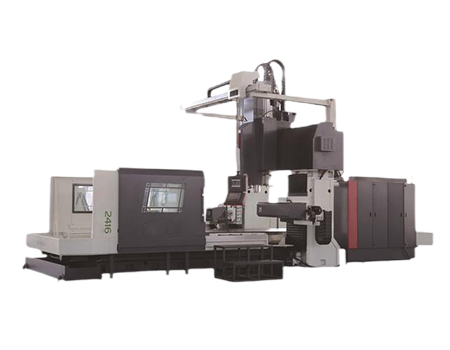

Bridge gantry type machining center BH4030/BH5030/BH6030 Series

Bridge-type gantry machining center is a type of machining center with a fixed table and a crossbeam that moves on two overhead bridges. The design of this structure allows the bridge-type gantry machining center to perform multi-axis precision machining with high stability and accuracy when machining large workpieces.

- Table size: 6000*2800mm

- Table maximum load: 2500kg/m²

- X/Y/Z axis travel: 6000*3000*1000mm

Project | Specification | Unit | BH4030 | BH5030 | BH6030 |

Worktable | Table width |

| 2800 | ||

Table length | mm | 4000 | 5000 | 6000 | |

Distance between two columns | mm | 3800 ( 3500) | |||

Max. load of table | Kg/m² | 2500 | |||

T-slots width * distance | mm | 28×200 | |||

Travel | X axis travel | mm | 4000 | 5000 | 6000 |

Y axis travel | mm | 3000 | |||

Z axis travel | mm | 1000 | |||

X,Y, Z axis feed speed | mm/min | 1-10000 | |||

X, Y,Z axes rapid speed | m/min | 10/15/10 | |||

Spindle | Distance from spindle nose to table surface | mm | 200-1200 | ||

Spindle taper |

| BT50-190(direct connection) | |||

Spindle motor | KW | 22/26 | |||

Spindle transmission |

| 2 steps variable speed with gear structure | |||

Max. torque of spindle | N. M | 760 | |||

Max. spindle speed | rpm | 6000 | |||

Magazine | Magazine capacity | N0. | 24/32 | ||

Magazine type |

| Umbrella magazine | |||

Max. tool diameter | mm | φ127/215 | |||

Max. tool length | mm | 300 | |||

Max. tool weight | Kg | 15 | |||

Positioning accuracy | Positioning accuracy-X | mm | 0.025 | 0.035 | 0.045 |

Positioning accuracy-Y | mm | 0.02 | |||

Positioning accuracy-Z | mm | 0.02 | |||

Repeatability Positioningaccuracy(Semi-closedLoop) | Repeatability Positioning accuracy-X | mm | 0.016 | 0.025 | 0.03 |

Repeatability Positioning accuracy-Y | mm | 0.014 | |||

Repeatability Positioning accuracy-Z | mm | 0.012 | |||

Overall dimension | mm | 10800×7200×4300 | 11800×7200×4300 | 12800×7200×4300 | |

Features

Bridge gantry machining center is a high-precision, high-efficiency, high-stability, easy-to-operate machining equipment with a high degree of automation and multi-functionality to meet the needs of different types, sizes and complexity of parts processing.

Modular gears with two-speed + spindle direct-connected design or built-in spindle design provide different cutting characteristics to meet diversified machining needs.- 2,500kg/m2 heavy-duty stationary table meets various machining requirements for heavy workpieces.

- Floor-mounted tool magazine is located at the back of the machine for quick tool change and easy operation and maintenance.

- Large separated water tank and spiral chip conveyor on both sides of the table facilitate maintenance, improve chip removal efficiency and ensure cooling performance.

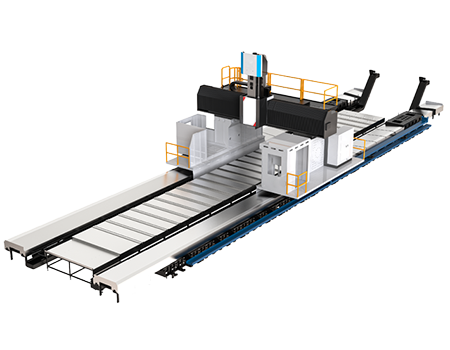

- The overhead bridge structure design provides excellent and stable dynamic accuracy, and at the same time, the footprint is reduced by more than 40% compared with the fixed-column model.

- The main body of the machine is a cross-rail bridge structure, so that the machine can provide the same dynamic characteristics when carrying different workpiece weights, high rigidity of the machine, and reduce the footprint, high space utilization. The internal design of the crossbeam has a fine-tuning structure to make up for the sagging and twisting of the middle part of the crossbeam caused by the self-weight of the headstock.

- The spindle constant power range is wide, and the spindle bearing adopts high-precision, high-rotation speed and high rigidity bearings, so that the spindle operates with high precision, low noise, low vibration and low thermal deformation, and the spindle head has high output torque and high cutting torque.The X, Y and Z coordinate axes adopt AC servo motors and heavy-duty linear rolling guideway sub, which have strong load bearing and anti-distortion ability, small friction coefficient, fast response speed and good stability, and can realize high-speed and high-precision Positioning.

- Intelligent automatic compensation of gravity effect in the Z-axis counterweight system closed loop design, can quickly compensate for the gravity effect generated by the movement, and can minimize the motor load.

- Equipped with intelligent non-contact tool setting instrument, using NC4 automatic tool setting allows the machine tool to have the intelligent management ability of self-judgment and decision-making, thus realizing unattended fully automated machining. Reduced scrap rate, high flexibility and reliable operation.

Applications

- Bridge gantry machining centers are mainly used for multi-species machining of complex parts in the aerospace industry. It occupies a large advantage in the production and processing of aluminum components. The workpiece can be clamped once to complete the five-face machining and multi-space milling and drilling of multiple processes with high efficiency and high precision.

- It is widely used in aviation, aerospace, automotive, mold and other industries.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com