PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

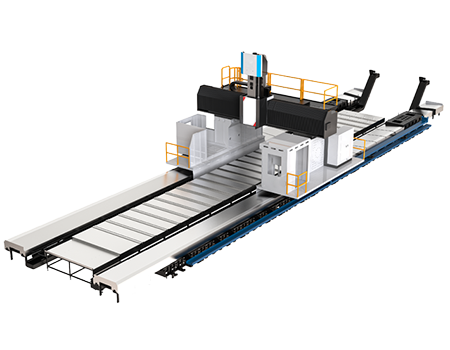

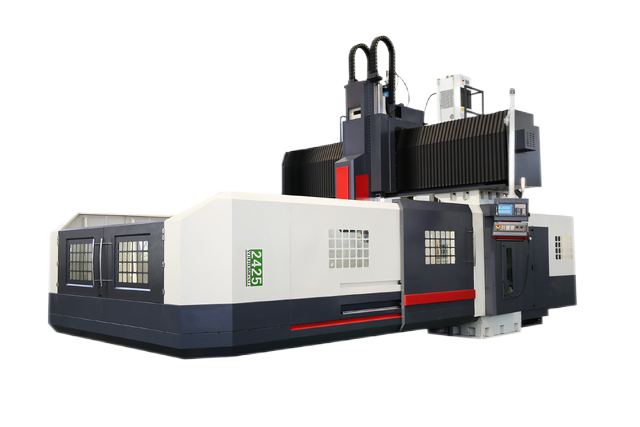

CNC Gantry Drilling And Milling Machining CenterXH1516 XH1520 XH1530 XH1625 Series

cnc gantry drilling and milling machining center XH1516 XH1520 XH1530 XH1625 series belongs to a light machining center adopts fixed bed, gantry moving; the spindle box moves up and down with the skateboard; it can also move left and right along the crossbeam to realize the three-axis linkage; it is configured with 11kw main boring and milling head. It is mainly used for CNC milling, boring, drilling and tapping of steel, cast steel and cast iron workpieces.

- Table size: 1600x1300mm

- Table maximum load: 1600kg

- X/Y/Z axis travel: 1600*1500*750mm

| Specification | unit | XH1516 | XH1520 | XH1530 | XH1625 | ||

| Worktable | Table width | mm | 1300 | 1300 | 1300 | 1600 | |

| Table length | mm | 1600 | 2000 | 3000 | 2500 | ||

| Max. load of table | kg | 1600 | 2200 | 2400 | 3000 | ||

| T slots(width/distance/number) | 22×130×9 | 22×130×9 | 22×130×9 | 22×180×9 | |||

| Travel | X axis Travel | mm | 1600 | 2000 | 3000 | 2500 | |

| Y axis Travel | mm | 1500 | 1500 | 1500 | 1800 | ||

| Z axis Travel | mm | 750/500 | 750/500 | 750/500 | 750/500 | ||

| Distance from spindle nose to worktable | mm | 150-900/650 | 150-900/650 | 150-900/650 | 150-900/650 | ||

| Distance between two columns | mm | 1600 | 1600 | 1600 | 1800 | ||

| Spindle | Spindle taper | BT50-160 | BT50-160 | BT50-160 | BT50-160 | ||

| Spindle motor | kw | 11/15 | 11/15 | 11/15 | 11/15 | ||

| Spindle speed | rpm | 6000/3000 | 6000/3000 | 6000/3000 | 6000/3000 | ||

| Magazine capacity | T | 24 | 24 | 24 | 24 | ||

| Feed speed(X/Y/Z axis) | mm/min | 1-8000 | 1-8000 | 1-8000 | 1-8000 | ||

| Rapid feed speed(X/Y/Z axis) | m/min | 12/12/8 | 12/12/8 | 12/12/8 | 12/12/8 | ||

| Positioning accuracy (Semi-closed Loop) | Positioning accuracy-X | mm | 0.020 | 0.020 | 0.030 | 0.030 | |

| Positioning accuracy-Y | mm | 0.020 | 0.020 | 0.020 | 0.020 | ||

| Positioning accuracy-Z | mm | 0.020 | 0.020 | 0,020 | 0,020 | ||

| Repeatable positioning accuracy (Semi-closed Loop) | Repeatability Positioning accuracy-X | mm | 0.015 | 0.015 | 0.020 | 0.020 | |

| Repeatability Positioning accuracy-Y | mm | 0.015 | 0.015 | 0.015 | 0.015 | ||

| Repeatability Positioning accuracy-z | mm | 0.015 | 0.015 | 0,015 | 0.015 | ||

| Overall dimension | mm | 4700×3300×35003750 | 5600×3300×3500/3750 | 7600×3300×3500/3750 | 6300×3300×3700/4000 | ||

| Weight | T | 12.5 | 14 | 18 | 18 | ||

Features

Gantry part: The crossbeam and column are box-type structure, and the internal layout is tic-tac-toe reinforcement, which has enough rigidity for the loads of up and down, left and right cutting as well as twisting of the spindle, and it is resistant to strong cutting and has high precision.

Bed part: Within ten meters of the bed are used as a whole casting structure, spiral chip conveyor groove and the bed as a whole casting, to prevent leakage, the bed inside the tic-tac-toe square lattice structure, effectively reduce the amount of deformation, the bed on the upper part of the two sets of guide rails line rail grooves, a clamping of the whole process.

Crossbeam part: Adopting larger column and crossbeam box structure support to ensure rigidity, the crossbeam adopts slanting back step design, two sets of heavy-duty roller rails are mounted on the upper plane, and one set of heavy-duty roller rails are mounted on the vertical plane, which effectively disperses the center of gravity of the headstock, and the widened chute is subjected to wide force and good rigidity.

Slider part: Spindle head guide (headstock) is a wide, high rigidity rectangular end shape, and the beam into a 90 ° semi-circumference structure, and ram within the package of hard rail combination, inclusive length of more than 1/2, the center of gravity of the headstock is close to the beam, in order to achieve the precision of the movement and the ability of heavy chip cutting, the overall structure highlights the unique high stability.

Ram part: Stronger Z-axis high rigidity hard rail, the thickness of the guideway is quenched and then tightly ground more than 85mm, strong rigidity is suitable for heavy cutting.

- Shovel scraping part: ram guideway surface paste molding process, combined with the surface of the manual shovel scraping process, to ensure that the machine tool combined with the surface of the larger, machine tool precision is good, high precision retention, scraping and researching the surface of the lubricating oil, to ensure that the guideway is fully lubricated for durability.

Applications

- CNC gantry drilling and milling machining center is mainly used for processing steel parts, cast steel parts, cast iron parts and other workpieces, CNC milling, boring, drilling, tapping, etc. The machine tool uses an attachment head to achieve a variety of discs, plates, shells, molds, and other complex parts in a single clamping to complete a variety of processes in the five-face machining.

- Widely used in machinery, steel, energy, automotive, aerospace, weapons, ships and other industries, large and medium-sized parts processing.

Standard Accessories

Siemens 828D system

24 tools arm type magazine

Spiral chip conveyor

Chain-type chip conveyor

Optional Accessories

FANUC Oi MF, MitsubishiM8O, KND, GSK, SYNTEC, Fagor

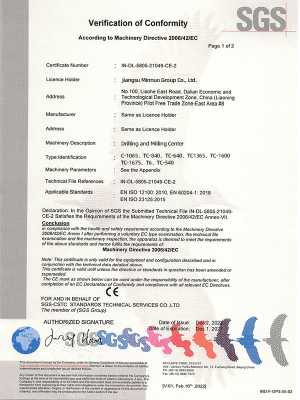

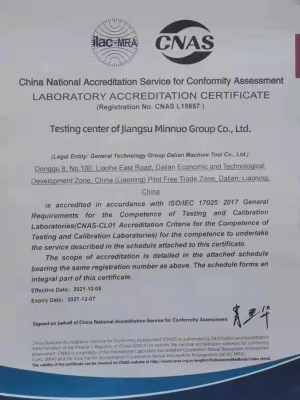

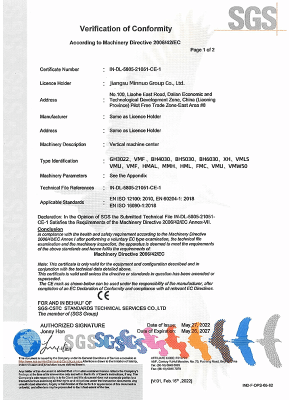

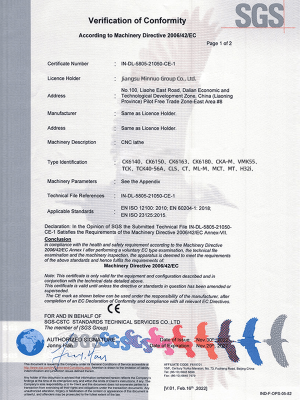

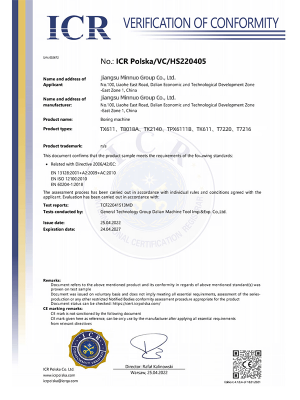

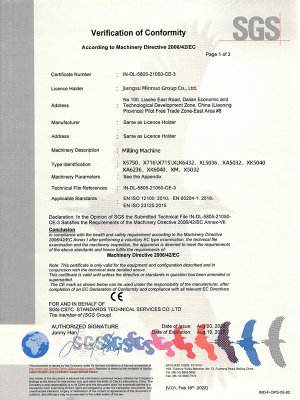

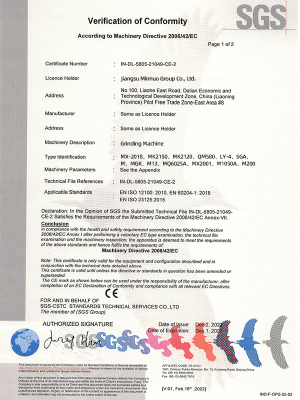

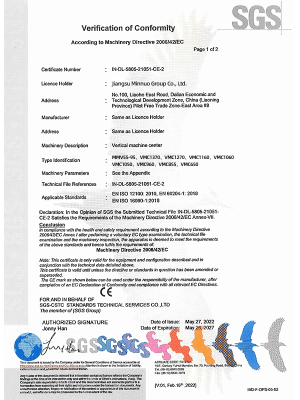

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com