PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

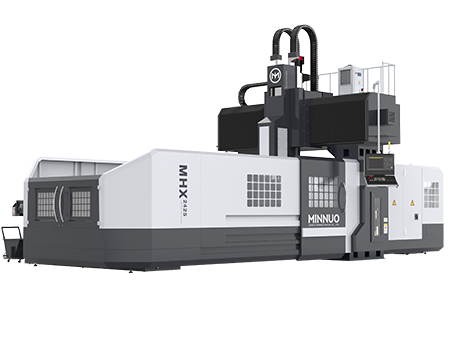

Double Z-axis Gantry Machining Centers XH Series - XH6032/XH8032/XH6038/XH8038

Dual Z-axis gantry machining centers are high-precision CNC machine tools with two Z-axis travel tracks that are typically used to perform multi-dimensional, high-efficiency machining tasks. It is widely used for rapid prototyping, small batch production and the manufacture of workpieces with specific shapes or high accuracy requirements.

- Table size: 8000*3000mm

- Table maximum load: 4000kg

- X/Y/Z axis travel: 8200/4400/1200mm

| Specification | Unit | XH6032 | XH8032 | XH6038 | XH8038 | |

| Worktable | Table width | mm | 2500 | 3000 | ||

| Table length | mm | 6000 | 8000 | 6000 | 8000 | |

| Max. load of table | kg | 30000 | 38000 | 35000 | 40000 | |

| T-slots(width/distance/number) | 28×200×11 | 28×200×15 | ||||

| Travel | X axis Travel | mm | 6200 | 8200 | 6200 | 8200 |

| Y1/Y2 axis Travel | mm | 3500/3500 | 4400/4400 | |||

| Z1/Z2 axis Travel | mm | 1200/1200 | 1200/1200 | |||

| Distance from spindle nose to worktable | mm | 250-1450 | 250-1450 | |||

| Distance between two columns | mm | 3200 | 3800 | |||

| Spindle | Spindle taper | BT50-190 | BT50-190 | |||

| Spindle motor | kw | 22/26 | ||||

| Spindle speed | rpm | 3000/6000 | 3000/6000 | |||

| Positioning accuracy(Semi-closed loop) | Positioning accuracy-X | mm | 0.040 | 0.050 | 0.040 | 0.050 |

| Positioning accuracy-Y | mm | 0.030 | 0.030 | 0.035 | 0.035 | |

| Positioning accuracy-Z | mm | 0.020 | 0.020 | 0.020 | 0.020 | |

| Repeatability positioning accuracy(Semi-closed loop) | Repeatability Positioning accuracy-X | mm | 0.030 | 0.035 | 0.035 | 0.035 |

| Repeatability Positioning accuracy-Y | mm | 0.020 | 0.020 | 0.020 | 0.020 | |

| Repeatability Positioning accuracy-Z | mm | 0.014 | 0.014 | 0.014 | 0.014 | |

| Overall dimension | mm | 15000×6900×5400 | 20000×6900×5400 | 15000×9200×6200 | 20000×9200×6200 | |

| Weight | T | 82 | 100 | 86 | 110 | |

Features

Dual Z-axis gantry machining centers are typically used for complex three-dimensional machining, allowing two tools or machining heads to move independently along two Z-axes, enabling different areas of the workpiece to be machined simultaneously or sequentially. This machine design improves machining efficiency, reduces the number of workpiece setups, and allows for finer machining operations.

Dual Z-axis travel track: Compared to traditional gantry machining centers, dual Z-axis gantry machining centers have two independent longitudinal travel axes, where one main axis is typically used for vertical machining and the other sub-axis is used to perform auxiliary operations or parallel machining at the same time. This dual Z-axis design allows the machine to perform multiple processes simultaneously in a single work cycle, increasing machining efficiency.

High-precision machining: Double Z-axis gantry machining center usually adopts advanced CNC control system and precision transmission device, which can realize high-speed and high-precision machining. It can be used for a variety of high-precision machining tasks, including milling, drilling, tapping, punching, and contour cutting of complex parts.

Multi-station work: Dual Z-axis gantry machining centers are often equipped with automatic tool changers and workpiece rotary tables that can accommodate multiple tools and workpieces for continuous machining and multi-station work. These features allow the machine to automate production, improving productivity and machining quality.

Complex machining capability: suitable for the machining of complex workpieces, such as deep hole machining, five-axis linkage machining and so on.

Applications

- Double Z-axis gantry machining centers XH series can process a variety of precision parts manufacturing and large workpieces. Due to its high efficiency and high precision machining capability, the double Z-axis gantry machining center is also widely used for rapid sample manufacturing, small batch production, and manufacturing of workpieces with specific shapes or high precision requirements.

- They are widely used in aerospace, automotive manufacturing, electronic equipment, mold manufacturing and other industries.

Standard Accessories

Siemens 828D/FANUC Oi MF

Spiral Chip Conveyor

Chain-type Chip Conveyor

Optional Accessories

- Imported gear box

- Spindle oil cooling

- Manual right-angle milling head

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com

.png)