PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

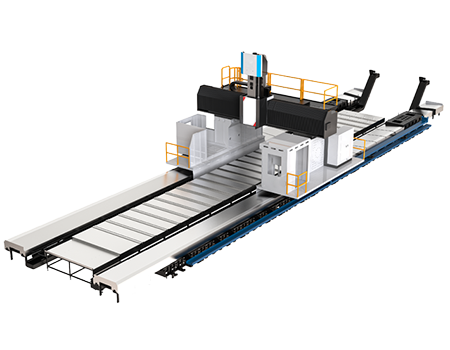

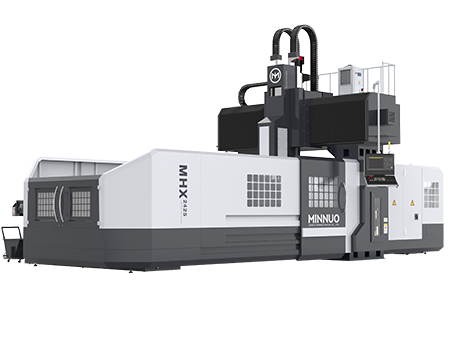

High-speed Gantry Machining Center GH3022

High-speed gantry machining center GH3022 is mainly applied to the machining of aluminum profiles, battery trays, frames, aviation aluminum parts and other non-ferrous metals, the machine tool runs at a fast speed and the spindle speed is high, the machine tool is the introduction of our company and digested and absorbed the advanced design and process technology of Europe, it has the characteristics of superior structural design, reliable accuracy stability and retention, easy operation, machining efficiency and so on.

- Table size: 3000×2000mm

- Table maximum load: 3000kg

- X/Y/Z axis travel: 3000/2000/700mm

Project | Specification | Unit | GH3022 |

Travel | X-axis Travel | mm | 3000 |

Y-axis Travel | mm | 2000 | |

Z-axis Travel | mm | 700 | |

Distance from spindle nose to worktable surface | mm | 130-830mm | |

Worktable | Worktable size | mm | 3000×2000 |

Max. load of table | kg | 3000 | |

Gantry width | mm | 2200 | |

T slot N/D/W | mm | 9/200/22 | |

Spindle speed | rpm | 12000 | |

Spindle | Commission type |

| Direct connection |

Tool clamping type |

| BT40 4-Valve claw | |

Spindle taper |

| BT40 | |

Feed | X/Y rapid speed | m/min | 40/40 |

Z rapid speed | m/min | 36 | |

Cutting feed speed | mm/min | 1~15000 | |

positioning accuracy | mm | 0.02/0.015/0.012 | |

Re-positioning accuracy | mm | 0.015/0.012/0.01 | |

Magazine | Magazine type |

| Disc type |

Magazine capacity |

| 24 | |

Max tool diameter/length/weight | mm, kg | φ75mm/300mm/8kg | |

Tool diameter while neighbor empty | mm | φ150 | |

Tool change time | sec | 3 | |

Overall size | Machine height | mm | 3500 |

Machine width+Chip conveyor | mm | 5200+1400 | |

Machine size | mm | 5200*4400*3800 |

Features

- High-speed spindle: capable of high rotational speeds, suitable for high-speed milling, up to 12,000 rpm

- Large travel: X, Y, Z axes have a large travel range of up to 3000/2000/700mm, adapting to the processing of large workpieces.

- Adopting German Siemens CNC system and professional CNC processing software to realize three-dimensional programming and processing.

- Imported high precision grade ball screws, guide rails, rack and pinion to ensure the stability of the machine.

- Adopting high speed, high torque and large diameter spindle to ensure high precision machining.

- Gantry type double-drive traveling, equipped with multi-station capacity tool magazine to ensure high efficiency machining.

Applications

- High-speed gantry machining centers are particularly suitable for machining large workpieces and workpieces with complex shapes, providing a wide range of applications.

- It is suitable for machining large workpieces in aerospace, shipbuilding, power generation, military, heavy machinery and other industries.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com