PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

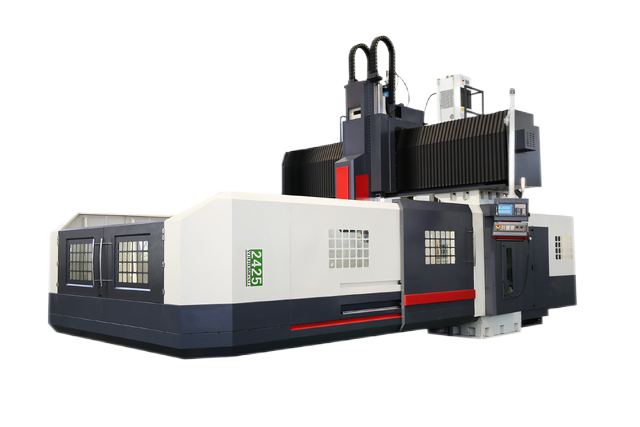

Movable Column Gantry Machine Center DH Series

The movable column gantry machining center DH series adopts a fixed workbench and moving column design to provide high-precision processing. Suitable for large and heavy workpieces. Combined with a rigid gantry structure and a high-performance control system, precise and complex machining can be achieved. Suitable for aviation, automobile and mold industries, etc.

- Table size: 3000x16000mm

- Table maximum load: 1000kg

- X/Y/Z axis travel: 16200*4800*1250mm

| Main technical parameters | unit | DH16042 | DH12042 | DH20042 | DH2404 2 | DH16052 | DH12052 | DH20052 | DH24052 | |

| Table width | Table width | mm | 3000 | 3000 | 3000 | 3000 | 4000 | 4000 | 4000 | 4000 |

| Table length | mm | 16000 | 12000 | 20,000 | 20,000 | 1 6 000 | 12000 | 20,000 | 24,000 | |

| Table load-bearing | kg / ㎡ | 10000 | 10000 | 10000 | 10000 | 15000 | 15000 | 15000 | 15000 | |

| Processing range | X- axis travel | mm | 16200+750 (replacement) | 12200+750 (replacement) | 20200+750 (replacement) | 24200+750 (replacement) | 16200+750 (replacement) | 12200+750 (replacement) | 20200+750 (replacement) | 24200+750 (replacement) |

| Y axis travel | mm | 4800 | 4800 | 4800 | 4800 | 5600 | 5600 | 5600 | 5600 | |

| Z- axis travel | mm | 1250 | 1250 | 1250 | 1250 | 1250 | 1250 | 1250 | 1250 | |

| Distance from spindle end face to worktable | mm | 300 ~1550 | 300 ~1550 | 300 ~1550 | 300 ~1550 | 500 ~1750 | 500 ~1750 | 500 ~1750 | 500 ~1750 | |

| distance between two columns | mm | 4200 | 4200 | 4200 | 4200 | 5200 | 5200 | 5200 | 5200 | |

| Spindle | Tool holder specifications | — | BT50 | BT50 | BT50 | BT50 | BT50 | BT50 | BT50 | BT50 |

| Spindle speed | rpm | 4000 | 4000 | 4000 | 4000 | 3000 | 3000 | 3000 | 3000 | |

| Spindle motor power | w | 22/26 | 22/26 | 22/26 | 22/26 | 30/37 | 30/37 | 30/37 | 30/37 | |

| Ram section | mm | 500 × 500 | 500 × 500 | 500 × 500 | 500 × 500 | 500 × 500 | 500 x500 | 500 × 500 | 500 × 500 | |

| Rapid traverse speed | XYZ axis rapid traverse speed | m/min | 2010/10/10 | 2010/10/10 | 2010/10/10 | 2010/10/10 | 2010/10/10 | 2010/10/10 | 2010/10/10 | 2010/10/10 |

| ATC tool change | Number of tools | — | 24/32/40/60 | 24/32/40/60 | 24/32/40/60 | 24/32/40/60 | 24/32/40/60 | 24/32140/60 | 24/32/40/60 | 24/32/40/60 |

| Tool maximum diameter / length / weight | mm / mm /kg | Φ 110/300/15 | Φ 110/300/15 | Φ 110/300/15 | Φ 110/300/15 | Φ 110/300/15 | Ф 110/300/15 | Φ 110/300/15 | Φ 110/300/15 | |

| Maximum diameter of tool (no adjacent tool) | mm | Φ 250 | Φ 250 | Φ 250 | Φ 250 | Φ 250 | Φ250 | Φ 250 | Φ 250 | |

| Machine tool accuracy | X- axis (Position / Repeat) | mm | 0.07/0.046 | 0.06/0.038 | 0.08/0.054 | 0.10/0.060 | 0.07/0.046 | 0.06/0.038 | 0.08/0.054 | 0.10/0.060 |

| Y axis (positioning / repeat) | mm | 0.03/0.02 | 0.03/0.02 | 0.03/0.02 | 0.03/0.02 | 0.04/0.03 | 0.04/0.03 | 0.04/0.03 | 0.04/0.03 | |

| Z axis (positioning / repeat) | mm | 0.02/0.013 | 0.02/0.013 | 0.02/0.013 | 0.02/0.013 | 0.02/0.013 | 0.02/0.013 | 0.02/0.013 | 0.02/0.013 | |

| CNC system | — | SIEMENS [ FAUNC ] or others | ||||||||

Features

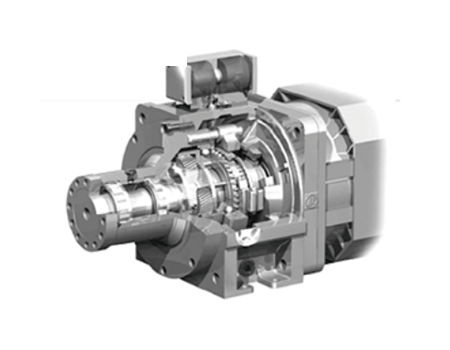

Modular gear two-speed + spindle direct connection design or A and C-axis linkage universal head design provide different cutting characteristics to meet diverse processing needs;

10000 kg/m2 heavy-duty fixed workbench can meet various requirements of heavy workpieces various processing needs;

The floor-standing tool magazine is configured on the rear side of the machine, which allows for quick tool changes and more convenient operation and maintenance;

Chain-type chip conveyors are equipped on both sides of the workbench to facilitate personnel maintenance and improve chip removal efficiency;

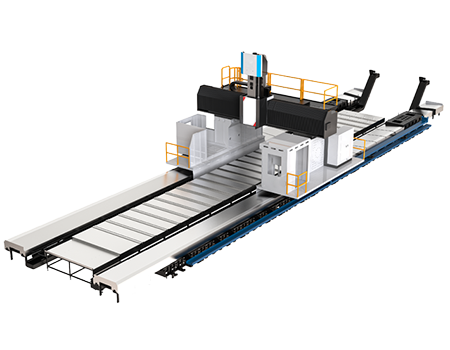

High rigidity The moving column structure design occupies less space than the fixed column model (the X-direction travel is preferably greater than or equal to 10 meters).

Applications

- Movable column gantry lathe DH series is characterized by strong steel, symmetrical structure, high stability, etc. By optimizing the structure of the basic parts, it improves the dynamic performance of the products and obtains the perfect combination of high power, high torque, high efficiency and high precision machining.

- It is suitable for large and heavy machining fields such as shipbuilding, metallurgy, petrochemical industry, mining machinery, electric power, engineering machinery, heavy machinery and so on.

Detailed Advantage

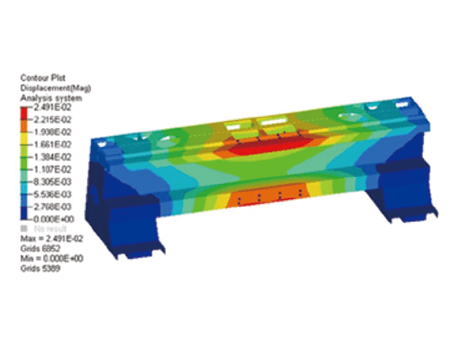

The movable column gantry machining center DH series are through finite element analysis, resins and shape, grid reinforcement plate layout, the foundation of the foundation parts have good shock absorption, thermal stability and rigidity, the emphasis of the machine structure and high rigidity, improve the performance of product processing.

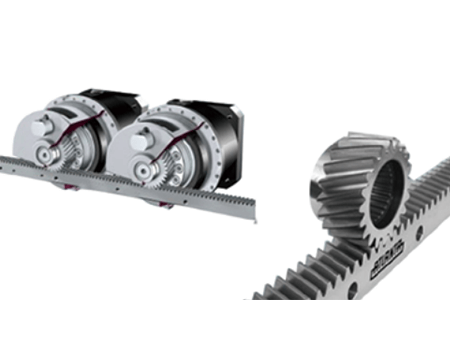

- X shaft adopts rack drive structure, two sets of imported precision planetary reducer are installed on one side, and the AC servo motor is directly connected to the precision planetary reducer device. The double motor electrical control is the clearance drive, and the gantry moving synchronization accuracy is high.

- The spindle speed adopts the gearbox structure to improve the output torque of the machine spindle, which is suitable for heavy cutting.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com