PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

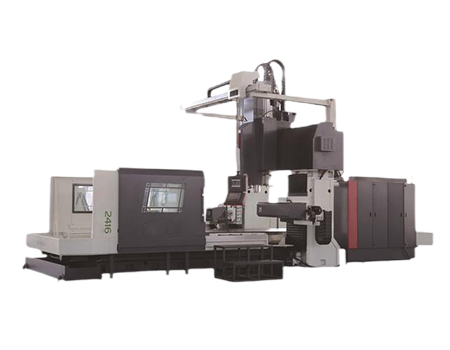

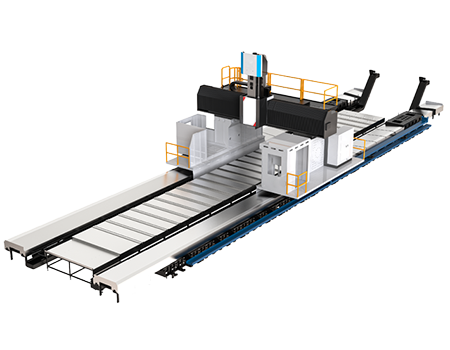

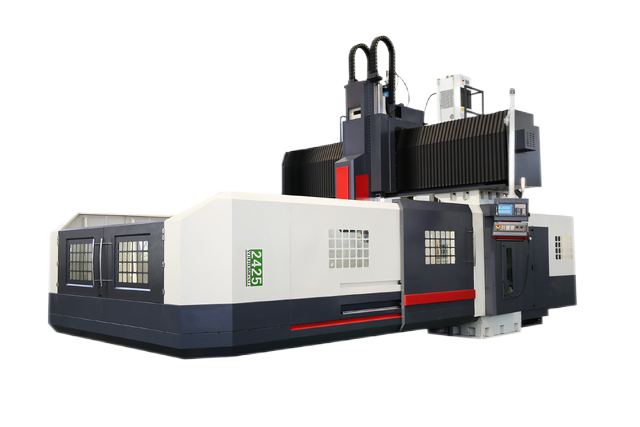

Vertical Horizontal Multi-Axis Gantry Machining Center XH Series—XH2014-CX2 XH2416-CX2 XH4030-CX2 XH6030-CX2

The Vertical and Horizontal Composite Gantry Machining Center is an advanced machine tool that combines the features of a Vertical Machining Center (VMC) and a Horizontal Machining Center (HMC) to be able to perform a wide range of machining tasks on a single machine. This series of machines is designed to increase productivity, reduce the number of workpiece setups, shorten cycle times, and enable the machining of complex parts.

- Table size: 6000*2200mm

- Table maximum load: 22000kg

- X/Y/Z axis travel: 6200*3150*1000mm

| Main technical parameters | unit | XH2014-CX2 | XH2416-CX2 | XH4030-CX2 | XH6030-CX2 | ||

| Worktable | Table width | mm | 1200 | 1600 | 2200 | 2200 | |

| Table length | mm | 2000 | 4000 | 4000 | 6000 | ||

| Max. load of table | kg | 5000 | 10000 | 15000 | 22000 | ||

| T-slots(width/distance/number) | 22×140×7 | 22×180×9 | 28×200×11 | 28×200×11 | |||

| Travel | X axis Travel | mm | 2100 | 4100 | 4200 | 6200 | |

| Y axis Travel | mm | 1400 | 2200 | 3150 | 3150 | ||

| Z axis Travel | mm | 800 | 1000 | 1000 | 1000 | ||

| W1/W2 travel(side head up-down) | mm | 600 | 800 | 850 | 850 | ||

| V1/V2 travel(side head left-right) | mm | 300 | 400 | 450 | 450 | ||

| Distance between two columns | mm | 1400 | 2100 | 3000 | 3000 | ||

| Spindle | Distance from spindle nose to worktable | mm | 150-950 | 200-1200 | 250-1250 | 250-1250 | |

| Spindle taper | BT50 | BT50 | BT50-190 | BT50-190 | |||

| Spindle motor | kw | 15-18.5 | 15-18.5/22-26 | 22/26 | 22/26 | ||

| Spindle speed | rpm | 6000 | 6000 | 6000 | 6000 | ||

| Side milling head | Distance from side head spindle center line to worktable | mm | 30-630 | 100-900 | 100-950 | 100-950 | |

| Spindle taper of side head | BT40 | BT40 | BT50 | BT50 | |||

| Spindle motor of side head | kw | 11/15 | 11/15 | 11/15 | 11/15 | ||

| Spindle speed of side head | rpm | 6000 | 6000 | 6000 | 6000 | ||

| Distance between spindle noses of the two side heads | mm | 700-1300 | 1300-2100 | 2100-3000 | 2100-3000 | ||

| Feed speed(X/Y/Z axis) | mm/min | 1-8000 | 1-8000 | 1-8000 | 1-8000 | ||

| Rapid feed speed(XTY/Z axis) | m/min | 12/12/10 | 12/12/10 | 10/12/10 | 10/12/10 | ||

| W/V spindle speed(variable) | mm/min | 1-6000 | 1-6000 | 1-6000 | 1-6000 | ||

| Positioning accuracy (Semi-closed Loop) | Positioning accuracy-X | mm | 0.016 | 0.025 | 0.025 | 0.040 | |

| Positioning accuracy-Y | mm | 0.015 | 0.02 | 0.020 | 0.020 | ||

| Positioning accuracy-Z | mm | 0.015 | 0.020 | 0.020 | 0.020 | ||

| Positioning accuracy-W | mm | 0.015 | 0.015 | 0.015 | 0.015 | ||

| Positioning accuracy-V | mm | 0.015 | 0.015 | 0.015 | 0.015 | ||

| Repeatability Positioning accuracy(Semi-closed Loop) | Repeatability Positioning accuracy-X | mm | 0.012 | 0.016 | 0.016 | 0.025 | |

| Repeatability Positioning accuracy-Y | mm | 0.010 | 0.014 | 0.014 | 0.014 | ||

| Repeatability Positioning accuracy-Z | mm | 0.010 | 0.014 | 0.014 | 0.014 | ||

| Repeatability Positioning accuracy-W | mm | 0.012 | 0.012 | 0.012 | 0.012 | ||

| Repeatability Positioning accuracy-V | mm | 0.012 | 0.012 | 0.012 | 0.012 | ||

| Overall dimension | mm | 6200×4500×4200 | 10000×5100×4800 | 10300×6200×5600 | 15000×6200×5600 | ||

| Weight | T | 17 | 34 | 50 | 62 | ||

Features

Combined by horizontal and vertical machining centers, it shares a set of working plane system and is equipped with rotary indexing device, which can be rotated at any angle to realize multi-face, turning and milling composite machining;

Equipped with a set of special processing CNC system, can efficiently complete the processing.

Vertical and horizontal combination structure design, that is, to expand the overall layout of the machine tool range, but also to avoid tool interference, a clamping, reduce the error of multiple clamping, improve accuracy.

The system is simplified and energy-saving, cost-saving, energy-saving, and reduced footprint.

Applications

- Vertical-horizontal compound gantry machining center is a highly flexible, high-precision machine tool, suitable for production environments that require a variety of machining methods and processing of large workpieces, especially suitable for high-efficiency, high-precision machining of complex shapes and polyhedral parts.

- This model is suitable for precision processing of large workpieces such as aerospace, automobiles, textile machinery, molds, packaging machinery, and mining equipment.

Related Products

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com