PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

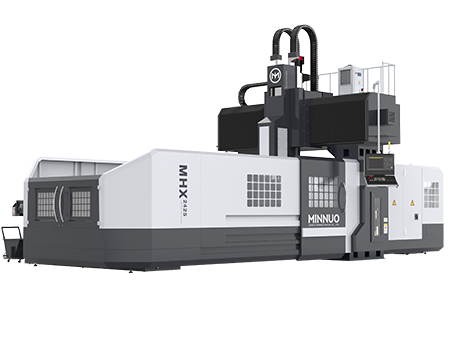

CNC Fixed Beam Gantry Type Machining Center XH Series

High-speed gantry machining center GH3022 is mainly applied to the machining of aluminum profiles, battery trays, frames, aviation aluminum parts and other non-ferrous metals, the machine tool runs at a fast speed and the spindle speed is high, the machine tool is the introduction of our company and digested and absorbed the advanced design and process technology of Europe, it has the characteristics of superior structural design, reliable accuracy stability and retention, easy operation, machining efficiency and so on.

- Table size: 3000×2000mm

- Table maximum load: 3000kg

- X/Y/Z axis travel: 3000/2000/700mm

| Specification | unit | XH6038 | XHG038 | XH8032 | XH6032 | XH5032 | XH4032 | XH8030 | XH6030 | XH4030 | XH3030 | XH6022 | XH4022 | XH3022 | XH3019 | XH2519 | XH2514 | XH2014 |

| table width | mm | 3000 | 2500 | 2200 | 1800 | 1500 | 1200 | |||||||||||

| table length | mm | 8000 | 6000 | 8000 | 6000 | 5000 | 4000 | 8000 | 6000 | 4000 | 3000 | 6000 | 4000 | 3000 | 3000 | 2500 | 2500 | 2000 |

| Max. load of table | kg | 40000 | 35000 | 38000 | 30000 | 26000 | 22000 | 30000 | 22000 | 15000 | 10000 | 15000 | 12000 | 10000 | 8000 | 7000 | 6000 | 5000 |

| T-slots(width/distance/number) | 28*200*15 | 28*200*11 | 28*200*11 | 28*180*9 | 22*160*9 | 22*14*7 | ||||||||||||

| X-axis Travel | mm | 8200 | 6200 | 8200 | 6200 | 5200 | 4200 | 8200 | 6200 | 4200 | 3200 | 6200 | 4200 | 3200 | 3100 | 2000 | 2600 | 2100 |

| Y-axis Travel | mm | 4200(4600、5800) | 3400 | 3150 | 2500 | 1900 | 1400 | |||||||||||

| Z-axis Travel | mm | 1200 | 1200 | 1000 | 1000 | 900 | 800 | |||||||||||

| Distance from spindle nose to worktable | mm | 250-1450 | 250-1450 | 250-1250 | 200-1200 | 150-1050 | 150-950 | |||||||||||

| Distance between two columns | mm | 3800(4200、5200) | 3200 | 3000 | 2200 | 1900 | 1400 | |||||||||||

| Spindle taper | BT50-190 | BT50-190 | BT50-190 | BT50-190 | BT50-190 | BT50-190 | ||||||||||||

| Spindle motor | kw | 22/26 | 22/26 | 22/26 | 15-18.5/22-26 | 15-18.5 | 15-18.5 | |||||||||||

| Spindle speed | rpm | 4000 | 6000 | 6000 | 6000 | 6000 | 6000 | |||||||||||

| Magazine capacity | 24 | 24 | 24 | 24 | 24 | 24 | ||||||||||||

| Feed speed(X/Y/Z axis) | mm/min | 1-8000 | 1-8000 | 1-8000 | 1-8000 | 1-8000 | 1-8000 | |||||||||||

| Rapid feed speed(X/Y/Z axis) | m/min | 10/12/10 | 10/12/10 | 10/12/10 | 12/12/10 | 12/12/10 | 12/12/10 | |||||||||||

| Positioning accuracy-X | mm | 0.050 | 0.040 | 0.050 | 0.040 | 0.035 | 0.025 | 0.060 | 0.040 | 0.025 | 0.020 | 0.040 | 0.025 | 0.020 | 0.020 | 0.018 | 0.018 | 0.016 |

| Positioning accuracy-Y | mm | 0.030 | 0.025 | 0.020 | 0.020 | 0.015 | 0.015 | |||||||||||

| Positioning accuracy-Z | mm | 0.020 | 0.020 | 0.020 | 0.018 | 0.015 | 0.015 | |||||||||||

| Re-positioning accuracy-X | mm | 0.035 | 0.030 | 0.035 | 0.030 | 0.025 | 0.016 | 0.035 | 0.025 | 0.016 | 0.013 | 0.026 | 0.016 | 0.012 | 0.012 | 0.012 | ||

| Re-positioning accuracy-Y | mm | 0.025 | 0.025(0.26/0.26) | 0.018 | 0.014 | 0.012 | 0.010 | 0.010 | ||||||||||

| Re-positioning accuracy-Z | mm | 0.014 | 0.014 | 0.013 | 0.012 | 0.010 | 0.010 | |||||||||||

| Dimension | m | 20*7.6*6.2 | 15*7.6*6.2 | 20*6.3*5.4 | 15*6.3*5.4 | 13*6.3*5.4 | 11*6.3*5.4 | 19*5.8*5.6 | 14.5*5.8*5.6 | 10.3*5.8*5.6 | 8.3*5.8*5.6 | 14.2*5.2*5.3 | 10.2*5.2*5.3 | 8.3*5.2*5.3 | 8.3*4.3*4.9 | 7.3*4.3*4.9 | 7.3*3.8*4.7 | 6.3*3.8*4.7 |

| Weight | T | 90 | 75 | 85 | 68 | 59 | 52 | 71 | 57 | 45 | 38 | 44 | 36 | 31 | 23 | 20 | 175 | 15 |

Features

The fixed beam type machining center machine tool for the gantry frame fixed, table moving structure, mainly consists of table, bed, column, beam, slide saddle, ram, hydraulic system, lubrication system, cooling and filtering system, chip removal device, rotary operating panel and electronic control system and other components.

- The bed, table, crossbeam and ram are all made of high-strength, high-quality cast iron to ensure the stability of the machining process;

- The transmission system adopts AC servo motor, through the imported low backlash reducer, directly drive the heavy load ball screw rotation, to realize the X-axis and Y-axis linear reciprocating motion, optional scale closed-loop detection.

- The spindle is made of high quality alloy steel, carburized and quenched, the spindle bearing assembly is made of imported high-precision spindle bearings, the spindle is equipped with thermostatic cooling system, the spindle is equipped with imported gearbox, synchronous toothed belt drive, high and low gears through the automatic shift to achieve the speed of the two gears, stepless speed regulation in each speed.

Applications

- The CNC fixed beam gantry machining center XH series is equipped with a variety of machining functions such as milling, boring, drilling (drilling, expanding, reaming), thread tapping and countersinking.

- It is suitable for the needs of various machining fields such as automotive, mold, aerospace, packaging, hardware and so on.

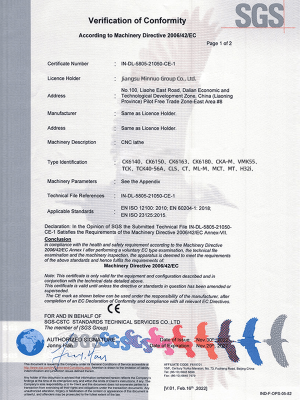

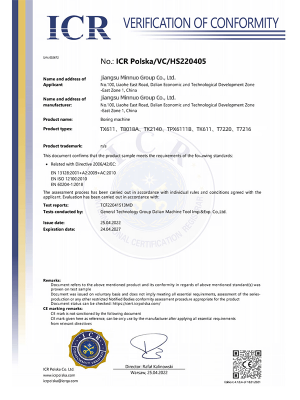

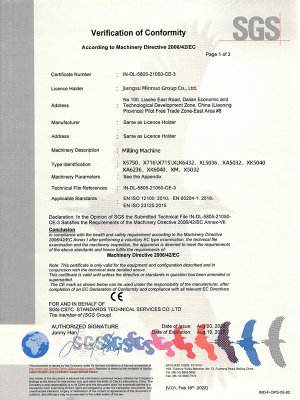

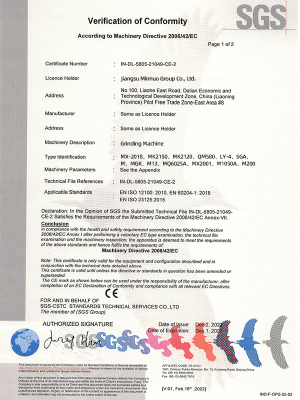

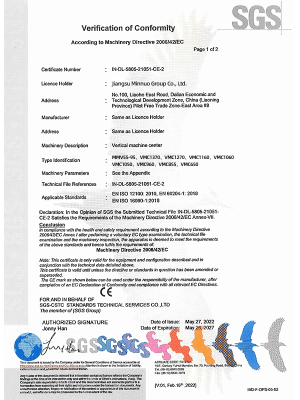

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com