PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

Y4830 CNC Internal Gear Honing Wheel Powerful Honing Machine

Gear honing machine is a gear processing machine that utilizes a gear-type or worm-type honing wheel to finish hardened cylindrical gears. The gear honing machine works on the principle of helical gear meshing, with the workpiece rotating freely driven by the honing wheel. Honing wheels are generally made of plastic and abrasive. The production efficiency of honing is high. Gear honing machine is widely used in automobile, tractor and machine tool manufacturing industries.

- Max. workpiece diameter: φ300mm

- Max. length of workpiece:400mm

- Max. gear width of workpiece: 120mm

Specifications | Unit | Y4830CNC |

Max. workpiece diameter | mm | φ300 |

Workpiece modulus | mm | 0.5~4 |

Workpiece pressure angle | ° | 14~40 |

Max. length of workpiece | mm | 400 |

Max. gear width of workpiece | mm | 120 |

Outside diameter of honer | mm | 400 |

Width of honer | mm | 20/24/30/40/50/60 |

Min. inside diameter of honer | mm | 220 |

Radial stroke of honer carrier (X-axis) | mm | -175~0 |

Max. radial feeding speed of honer carrier(X-axis) | mm/min | 7500 |

Axial stroke of honer carrier (Z1-axis) | mm | -403~97 |

Max. axial feeding speed of honer carrier (Z1-axis) | mm/min | 8000 |

Axial stroke of worktable (Z2-axis) | mm | -630~-100 |

Max. axial movement speed of worktable (Z2-axis) | m/min | 50 |

Tool post rotation angle (A-axis) | ° | 士45 |

Max. rotating speed of tool post (A-axis) | °/s | 112 |

Oscillating angle of column (B-axis) | ° | ±10 |

Max. oscillating speed of column (B-axis | °/s | 12 |

Max. speed of honer (Cl-axis) | rpm | 1500 |

Max. workpiece speed (C2-axis) | rpm | 6000 |

Max. honing force | N | 1000 |

Dimensions(L*W*H) | mm | 2650*2550*2650 |

Net weight | kg | 12000 |

Features

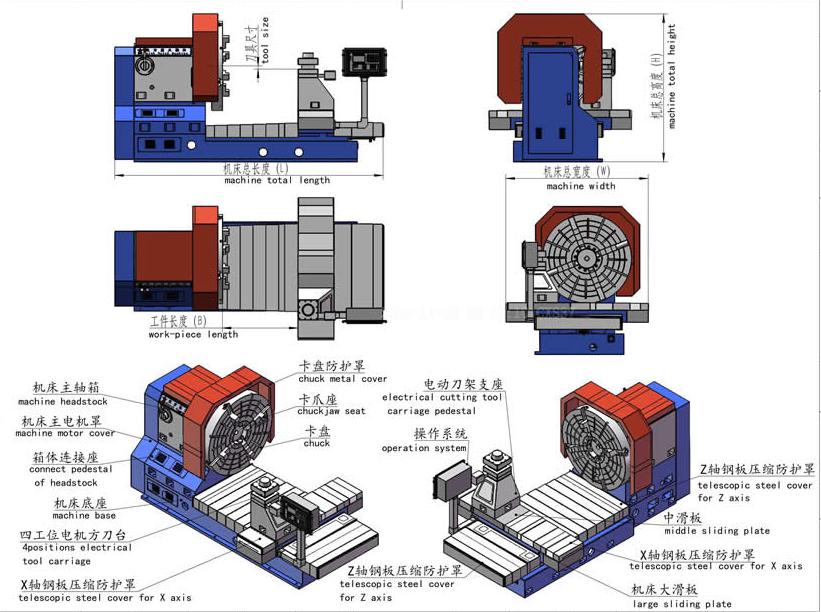

Y4830CNC belongs to 7-axis 5 linkage CNC internal gear honing wheel powerful honing machine, CNC axes are: honing wheel frame radial feed axis (X axis); honing wheel frame axial feed axis (Z1 axis); table axial feed axis (Z2 axis); honing wheel frame rotary angle rotary axis (A axis); column swing rotary axis (B axis); honing wheel rotary axis (C1 axis); worktable rotary axis (C2 axis). It can realize radial, axial and oscillating powerful honing processing mode, and the machine tool has seven-axis five linkage function.

- Gear honing significantly improves production efficiency, reduces gear noise, enhances gear load capacity, extends gear lifespan, and achieves a surface roughness of Ra0.63μm or lower, with gear precision reaching grades 5 to 6.

- The machine spindle and workpiece spindle use precision direct-drive technology, resulting in a short transmission chain and high machining accuracy.

- The user-friendly interface and proprietary software enable the automatic execution of powerful honing processes and automatic allowance compensation.

- The Z2 axis is driven directly by a linear motor, featuring intelligent clamping force control and automatic thermal deformation compensation technology to ensure the honing requirements for high-precision gears.

- For constant axis intersection angle machining, the system achieves constant force cutting. Workpiece phase detection and automatic gear alignment technology have been developed to automate the gear honing process.

- The machine utilizes the Siemens 840Dsl CNC system.

Applications

Gear Honing Machine is suitable for all kinds of straight teeth, helical teeth and shoulder gears after hardening, also can be used as gear grinding after finishing processing. Its function is to eliminate tooth surface burrs, oxidized skin, knocking injury, improve tooth shape, tooth direction, radial runout and circumference accuracy of tooth ring, reduce tooth surface roughness, reduce meshing noise.

Gear honing machine is widely used in automobile, tractor and machine tool manufacturing industries.

The above picture presents the internal structure of the CNC face lathe CK64 series machine and related details, if there is something you don’t understand you can contact us, our engineers will do one-to-one communication with you.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com