PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

YW5120 CNC Gear Shaping Machine

CNC gear shaping machine, a metal cutting machine tool, is a gear processing machine that uses a gear shaping cutter to process internal and external straight and helical cylindrical gears as well as other toothed parts according to the spreading method.

- Max. Workpiece diameter of external gear: 200mm

- Max. stroke length: 70mm

- Max. machineable gear width:60mm

Specifications | Unit | YW5120CNC | |

Max. workpiece | External gear | mm | 200 |

Internal gear | mm | 60+Tool | |

Max. modulus | mm | 6 | |

Max. stroke length | mm | 70 | |

Max. machineable gear width | mm | 60 | |

Spindle stroke number( Stepless) | str/ min | 400-2500 | |

Spindle diameter | mm | 85 | |

Distance from cutter installation plane to worktable plane | mm | 58-328 | |

Distance from cutter centerline to worktable centerline | mm | -30-200 | |

Diameter of worktable plane | mm | 200 | |

Worktable spindle bore diameter | mm | 75 | |

Worktable oscillating angle | 。 | ±10 | |

Radial back- off value at highest position of cutter spindle | mm | >0.5 | |

Radial feeding rate of column ( Stepless speed regulation) | mm/ str | 0.001 | |

Radial high- speed motion of column | mm/ min | 2000 | |

Max. rotating speed during fast running of worktable | rpm | 10.4 | |

Tool post slide stroke length | mm | 200 | |

Total power of machine | kW | 50 | |

Dimensions (L*W*H) | mm | 3305*2680*2800 | |

Net weight | kg | 10000 | |

Features

The YW5120 gear shaping machine is an eight-axis, five-linkage CNC gear shaper with a vertical layout where the column moves radially along the bed and the tool holder swings to accommodate the cutting movement. The eight axes are: radial feed movement X axis, tool circular movement C1 axis, workpiece circular movement C2 axis, crank rotation movement A axis, relieving cam movement B1 axis, worktable swing B2 axis, vertical movement of the tool holder slide Z axis, and stroke length adjustment Y axis. During gear shaping, the X, C1, C2, A, and B1 axes achieve five-axis linkage.

This machine is equipped with the Siemens 840DSL CNC system. It has the following features:

- The CNC gear shaper features an electronic helical guide function, allowing for the cutting of helical gears without the need for a special helical guide rail.

- It includes a tool holder slide lifting function, making it particularly suitable for shaping double gears with the same module but different tooth counts in a single clamping.

- The machine is designed with a CNC swing worktable, enabling the processing of not only small taper gears but also special tooth profiles.

- High production efficiency: The machine’s tool holder structure uses hydrostatic guides and hydrostatic bearings, meeting the needs for high-speed strokes with a maximum stroke speed of 2500 strokes per minute.

- High rigidity and thermal stability: The bed is made of high-density gray cast iron with a double-wall structure, providing excellent thermal stability and a stable foundation structure.

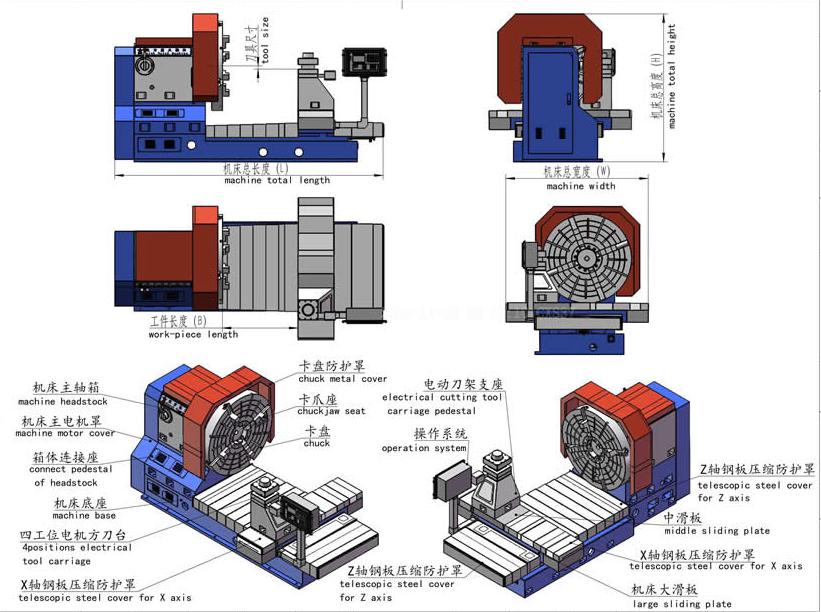

The above picture presents the internal structure of the CNC face lathe CK64 series machine and related details, if there is something you don’t understand you can contact us, our engineers will do one-to-one communication with you.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com