PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

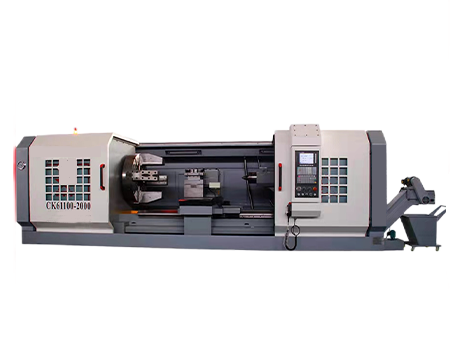

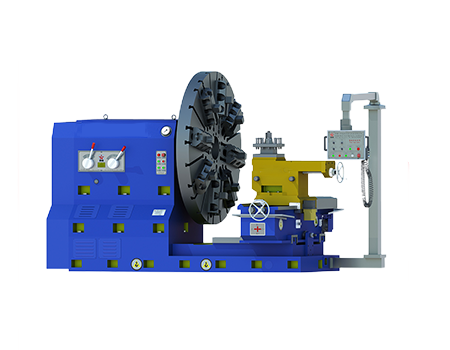

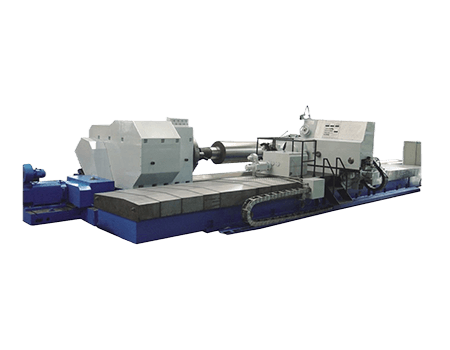

CNC Crankpin Lathe

CNC crankshaft connecting rod neck lathe is specially designed for turning crankshaft connecting rod diameter, the lathe has double spindle synchronization function, equipped with eccentric fixture, planetary center frame to ensure the accuracy of machining crankshaft connecting rod diameter. The machine is suitable for machining crankshafts for various large engines.

- Swing over carriage: 600~2000mm

- Max. load between centers: 0~300mm

- Bed width: 970~2050mm

Main specifications | Unit | CK43100 | CK43125 | CK43160 | CK43250 |

Swing over carriage | mm | 600 | 850 | 1250 | 2000 |

Adjustable range of eccentricity | mm | 0~105 | 0~160 | 0~260 | 0~300 |

Max. load between centers | ton | 6 | 6 | 10 | 63 |

Bed width | mm | 970 | 1100 | 1600 | 2050 |

Spindle speed | rpm | 16~200 | 12~ 160 | 2~120 | 0.8~ 160 |

Spindle motor | kW | AC17/22 | AC30/42 | DC55 | DC110 |

Machine weightof 3 meters | Kg | 18500 | 19500 | 30000 | 65 |

Add weight per meter | Kg | 1200 | 1250 | 2250 | 3200 |

Machine outlinesize of 3 meters | L*W*H | 7350*1850*1950 | 7850*2550*1950 | 15200*2450*2475 | 10500*4100*3100 |

Features

Electric servo bending machine realizes fast response and precise control through electric servo system, which improves productivity, reduces energy consumption, and lowers noise pollution. Its high-precision positioning capability ensures machining quality while reducing maintenance costs and enhancing the safety of the working environment.- Multi-axis linkage: CNC crankshaft connecting rod neck lathes are usually equipped with multi-axis linkage capability, which is capable of machining multiple surfaces at the same time, improving machining efficiency and machining quality.

- High precision: the adoption of high-precision CNC system and servo drive device can ensure high precision and repeatability in the machining process.

- High degree of automation: CNC crankshaft connecting rod neck lathe usually has a high level of automation, which can realize automatic loading and unloading, automatic measurement and automatic adjustment, reduce manual intervention and improve production efficiency.

- Strong adaptability: able to adapt to different specifications and models of crankshaft machining needs, by replacing or adjusting the CNC program, quickly adapt to product changes.

- Good rigidity and stability: the machine tool structure is reasonably designed, with good rigidity and stability, able to withstand large cutting force, to ensure the stability of the machining process and machining quality.

Applications

- CNC crankpin lathe is a special CNC equipment for machining various large eccentric shafts and crankshaft connecting rod journals. It can complete semi-finishing and finishing of crankshaft main journal and connecting rod journal: outer circle, round root, outer circle of crank arm, inner side of crank arm, inner corner of intersection of connecting rod neck and chamfering of outer circle of crank. It also has the function of processing the main shaft diameter of crankshaft. Suitable for carbon steel, alloy steel, cast steel, cast iron processing.

- It is suitable for precision turning of connecting rod necks of compressors, motorcycles, automobiles, diesel units, heavy trucks and large marine crankshafts, replacing the rough grinding process with high-speed and high-precision turning.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com