PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

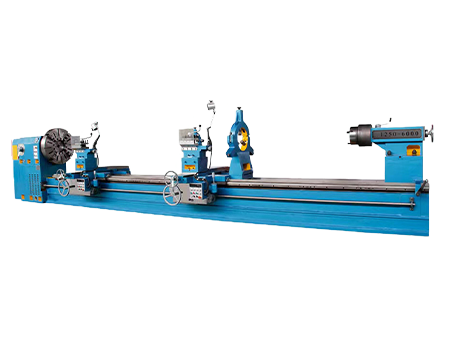

CNC Heavy Duty Flange Conventional Floor Lathe CK60Series

CNC Heavy Duty Flange Lathe CK60 series is a traditional floor lathe, which can be mainly used for all kinds of turning work, and is capable of turning the end face, outer circle and taper of all kinds of parts. The machine tool has the features of strong rigidity, high efficiency, energy saving, safety and reliability, easy operation and beautiful modelling.

- Max.swing diameter over machine bed : 1600/2000/2500/3000mm

- Max.swing diameter over cutting tool carriage: 1250/1600/2000/2500mm

- Max.work-piece weight: 1~3T

- Max.work-piece length: 500/750mm

Features

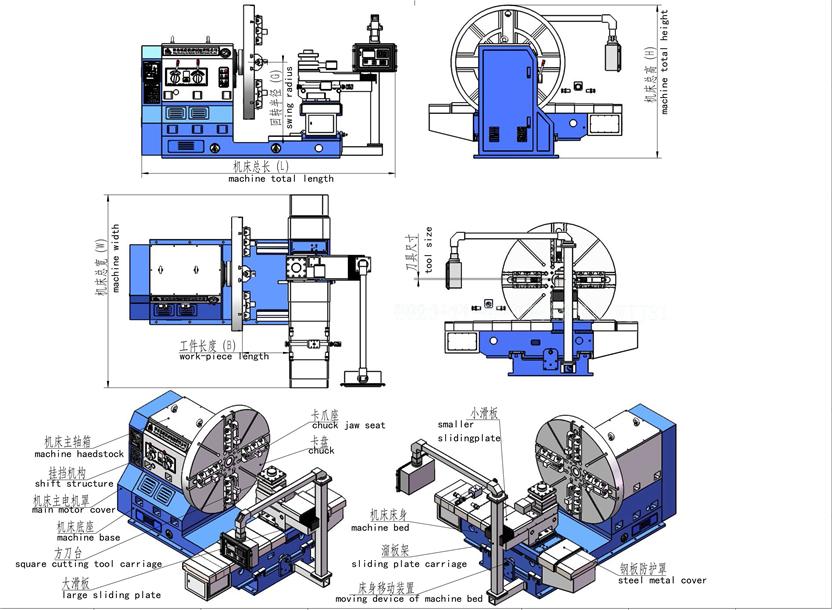

- The base rail adopts rectangular structure with large span, good rigidity and suitable for low-speed heavy-duty cutting.

- The structure of the floor lathe adopts the bed guideway with the head box spindle perpendicular to the movement of the pallet, and the head box and the transverse bed are connected to the same base, which is a mountain-type guideway structure, and the transverse movement of the pallet can be adjusted manually.

- This CK60 series lathe adopts frequency conversion speed control system as the main transmission system; the spindle speed is driven by the frequency conversion speed control motor to realise stepless speed regulation, with different speeds to meet the requirements of reasonable cutting speed for the processing of different types of workpieces.

Applications

- CNC Heavy Duty Flange Lathe CK60 series of machine tools have large load capacity, strong rigidity, beautiful appearance, easy to operate, capable of turning all kinds of parts inside and outside the cylindrical surface, end face, arc and other forming surfaces, is the processing of all kinds of wheels, tyre moulds and large plane discs, rings and other parts of the ideal equipment.

- Floor lathe is mainly used for turning heavy mechanical parts with large diameter, such as tyre moulds, large-diameter flange tube plate, turbine fittings, head, etc. It is widely used in the processing and manufacturing of petrochemical industry, heavy machinery, automobile manufacturing, mining and railway equipments as well as aeronautical parts.

CNC Heavy Duty Flange Conventional Floor Lathe CK60Series | ||||||

| Model | Unit | CK6016 | CK6020 | CK6025 | CK6030 |

Machining Technical Parameters | Max.swing diameter over machine bed | mm | 1600 | 2000 | 2500 | 3000 |

Max.swing diameter over cutting tool carriage | mm | 1250 | 1600 | 2000 | 2500 | |

Max.work-piece weight | T | 2T | 3T | |||

Max.work-piece length | mm | 500 | 750 | |||

Machine Bed Parameters | Guide rail type |

| Stepless variable frequency | |||

Guide rail width | r/min | 10-156 | 4-106 | |||

Headstock | Spindle speed | KW | 15 | 18.5 | 22 | |

Spindle speed range | mm | 1250 | 1600 | 2000 | 2500 | |

Main motor power | knm | 20 | 40 | |||

Max.X Axis stroke | mm | 800 | 1000 | 1250 | 1575 | |

Max.Z Axis stroke | mm | 500 | 750 | |||

Feed Data | Feed range of X Axis | mm/min | 1-200 | |||

Feed range of Z Axis | mm/min | 1-200 | ||||

Rapid moving range of X Axis | mm/min | 2000 | ||||

Rapid moving range of Z Axis | mm/min | 1500 | ||||

Other Data | Machine Length | mm | 3500 | 3500 | 4500 | 4500 |

Machine Width | mm | 2500 | 2800 | 3200 | 3500 | |

Machine Height | mm | 1800 | 2000 | 2500 | 3000 | |

Control System |

| Semi-automatic | ||||

The above picture presents the internal structure of the CNC face lathe CK60 series machine and related details, if there is something you don’t understand you can contact us, our engineers will do one-to-one communication with you.

Bus termination operation system

The machine adopts bus termination operation system.High advanced optional control system like GSK,SIEMENS, FANUC, etc with manual pulse generator to realize convenient operation with stable signal transmission and high accuracy control.

High accuracy head-stock

40Cr forged and ground gears are used in the headstock with 4 gear shifts speed regulation.All shafts are spline structure with tight fit. The standard configuration of bearings are brands with high accuracy. The gear meshes with high accuracy and low noise.

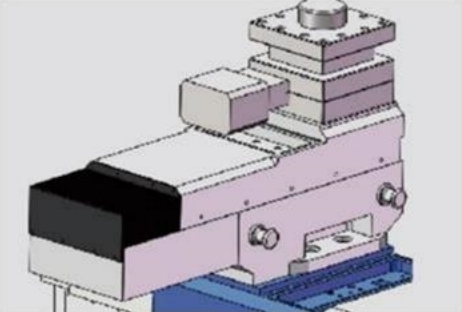

New designed heavy duty cutting tool carriage structure

Uniformed and reasonable layout of each layer of sliding plate. Excellent design of cutting tool carriage with large cutting volume and high stability. The smaller sliding plate directly connects with servo motor with large torque and high feed accuracy. 4 positions electrical circulation water outlet function for convenient cooling.

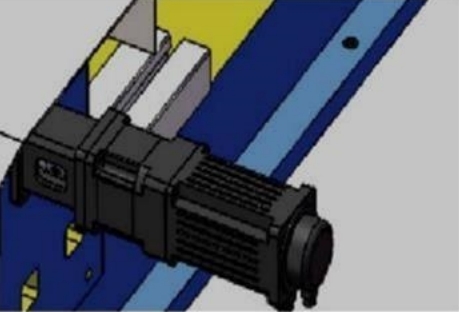

Large torque design of Z axis

Z axis servo motor directly connects with reduction box to drive the bail screw. Through the high precision planetary reduction box, the transmission torque is increased to ensure the power of tool carriage and cutting force of machine.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com