PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

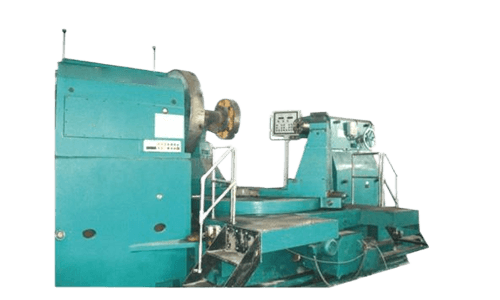

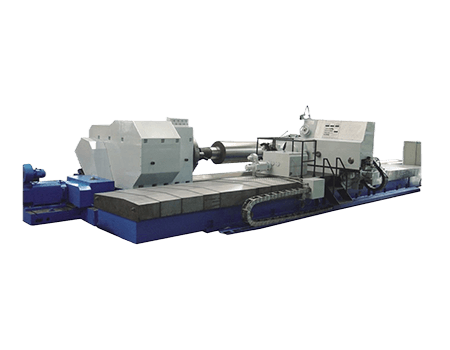

CNC Large Spindle Bore Lathe CK6628/CK6636/CK6646/CK6663 Series

CNC large bore tube lathe CK66 series is a high-precision CNC machine tool designed for large diameter tubular workpieces with automation control, multi-axis machining and automatic tool changer, suitable for machining all kinds of tubular threads, pipe hoops, drill rods and other parts. Its user-friendly operator interface and high stability design ensure machining efficiency and product quality, while providing customized solutions to meet specific needs.

- Swing over bed: 1000~1400mm

- Swing over carriage: 640~1100mm

- Spindle bore: 280~630mm

Specifications | Unit | CK6628 | CK6636 | CK6646 | CK6663 |

Swing over bed | mm | 1000 | 1000 | 1200 | 1400 |

Swing over carriage | mm | 650 | 640 | 800 | 1100 |

Spindle bore | mm | 280 | 360 | 460 | 630 |

Max. load between centers | ton | 4 | 6 | 6 | 10 |

Bed width | mm | 600 | 755 | 970 | 970 |

Spindle speed | rpm | 5~500 | 3.15~315 | 3.15~315 | 2~200 |

Spindle motor | Kw | AC18.5 | AC22 | AC30 | AC37 |

Machine weight of 3 meters | Kg | 6800 | 12000 | 14000 | 17000 |

Add weight per meter | Kg | 800 | 1000 | 1200 | 1200 |

Machine outline size of 3 meters | L*W*H | 5750*1650*1550 | 6300*1650*1700 | 6300*2550*1850 | 6300*2875*1850 |

Features

Large spindle bore CNC lathe CK66 series adopts pulse encoder as the detecting element, longitudinal and transverse feeding are driven by the same service motor to drive the ball screw, constituting semi-closed-loop control, equipped with CRT display, featuring tool compensation, graphic display, fault diagnosis, machining and programming at the same time, graphic display and fast programming, etc. The main transmission realizes automatic stepless speed change with sliding gears. The layout of the whole machine tool is compact and reasonable, with good habitability.

- Imported original German SIEMENS802DSL numerical control system and full digital AC servo system and spindle servo motor.

- The main turning motion realizes automatic stepless speed change with sliding gears, two linked control axes, and semi-closed-loop control for both X and Z axes.

- Ball screws are made of imported precision ball screws produced by German WMH company, which makes the machine have good positioning accuracy and repeatability.

- The tool rest is made of high performance 4-position CNC vertical tool rest from Yantai Machine Tool Accessory Factory (MTAF).

Applications

- The large spindle bore CNC lathe CK66 series is mainly used for processing all kinds of pipe threads, pipe hoops and drilling rods, and it can also process internal and external cylindrical surfaces, end surfaces, internal holes and all kinds of rotary surfaces.

- Widely used in oil and gas, electric power chemical industry, shipbuilding, water conservancy engineering and other industries.

Standard Accessories

- 4-jaw chuck

- Lighting unit

- Cooling unit

- Special tools

- Taper turning device

- Feed support device for work piece

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com