PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

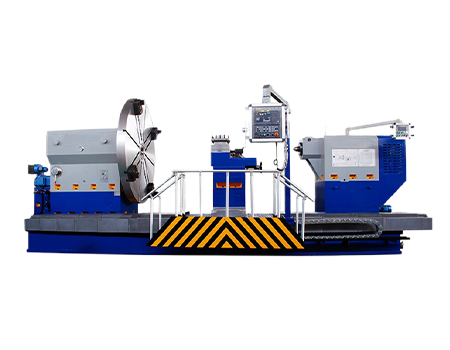

CNC Roll Grinding Machine M8480/M84100/M84125/M84160/M84200 Series

CNC roll grinding machine M84 series, the overall layout of which adopts the structure of separating workpiece bed and drag plate bed, is suitable for grinding work rolls and support rolls on roll machines in the metallurgical industry, rolls on paper machines in the papermaking industry, all kinds of pressure rolls in the rubber industry, and all kinds of metal rolls and non-metallic pressure rolls in the printing and dyeing industry.

- Max. grinding diameter: 800~2000mm

- Min. grinding diameter: 120~400mm

- Max. load of center rest: 12~63T

Specifications | Unit | M8480 | M84100/125 | M84160/200 |

Max. grinding diameter | mm | 800 | 1000/1250 | 1600/2000 |

Min. grinding diameter | mm | 120 | 150/200 | 300/400 |

Max. load of center rest | ton | 12 | 20/25 | 32~63 |

Convex(concave)(in radial) | mm | 1.5 | 1.5 | 1.5 |

Bed width | mm | Workpiece bed 725 | Workpiece bed 1100 | Workpiece bed 1320 |

Spindle speed | rpm | 8~80 | 6~60 | 4~40 |

Power of workpiece motor | Kw | 45 | 55/75 | 75/90 |

Power of grinding-wheel motor | Kw | 45 | 55/75 | 75/90 |

Machine weight of 5 meters | Kg | 38000 | 56000/62000 | 110000/128000 |

Add weight per meter | Kg | 3000 | 3500 | 5000 |

Machine outline sizeof 5 meters | L*W*H | 11500*3800*2600 | 12500*4600*2900/13500*5100*3100 | 14000*5300*3200/14000*5500*3300 |

Features

- CNC roll grinding machine overall layout adopts separated structure, which can avoid the influence of deformation caused by the weight of workpiece on the bed of grinding wheel holder on machining accuracy.

- The bed is designed by finite element method, with reasonable layout of ribbed plate, and the material is made of HT300 high grade high quality gray cast iron.

- The headstock of the roll grinder is driven by a high-performance DC motor, featuring a large starting torque and good low-speed performance.

- The tailstock consists of upper and lower bodies, the double-layer tailstock is convenient for adjusting the accuracy of the horizontal direction of the two centers, and the tailstock is equipped with an electronic display meter of the workpiece holding force, which is convenient for observing the holding force of the workpiece, and at the same time, according to the weight of the workpiece and the angle of the centers, the appropriate holding force can be selected.

- The grinding wheel holder is one of the core components of the roll grinder, and its rotary accuracy and smoothness of movement directly affect the grinding quality of the surface of the workpiece. The grinding wheel holder of Minnuo’s roll grinding machine has reached the international advanced level.

- The large drag plate guide rail is in the form of V-flat structure and adopts the paste plastic static pressure technology, the movement of the large drag plate has good low-speed movement characteristics, which can effectively eradicate the crawling, and the movement has high precision and no wear and tear.

Applications

- CNC roll grinding machines can accomplish the grinding of cylindrical, medium-convex or medium-concave curved roll surfaces.

- It is widely used for grinding work rolls and support rolls on roll machines in the metallurgical industry, rolls on paper machines in the papermaking industry, various kinds of pressure rolls in the rubber industry, and various kinds of metal rolls and non-metal pressure rolls in the printing and dyeing industry.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com