PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

Conventional End Face Lathe

Conventional mechanical end face lathe is a manually operated metal cutting machine tool with mechanical transmission, high rigidity structure and multi-functional tooling system for external round, end face and thread machining of various metal materials. It is characterized by manual control, intuitive operation, cost-effectiveness and easy maintenance, and still has application value in single-piece and small-lot production.

- Max.swing diameter over machine bed: 1250~3000mm

- Max.swing diameter over cutting tool carriage: 800~2500mm

- Max.workpiece weight: 2~3T

- Max.workpiece length: 500~750mm

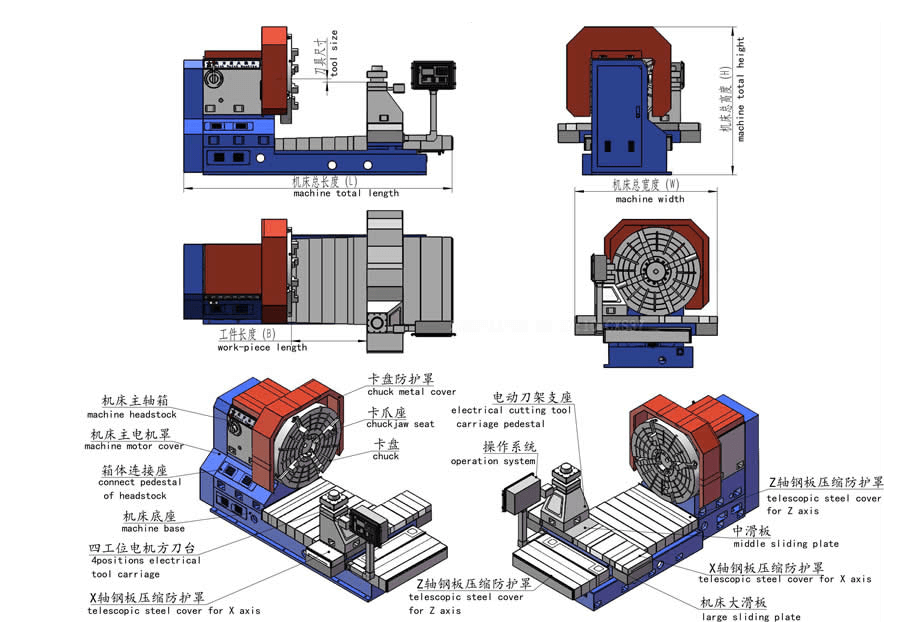

CK64 Facing CNC Lathe | |||||||

| Model | Unit | CK64125 | CK64160 | CK64200 | CK64250 | CK64300 |

Machining Technical Parameters | Max.swing diameter over machine bed | mm | 1250 | 1600 | 2000 | 2500 | 3000 |

Max.swing diameter over cutting tool carriage | mm | 800 | 1250 | 1600 | 2000 | 2500 | |

Max.work-piece weight | T | 2T | 3T | ||||

Max.work-piece length | mm | 500 | 750 | ||||

Machine Bed Parameters | Guide rail type |

| Stepless variable frequency | ||||

Guide rail width | r/min | 6-210 | 5-140 | 4-106 | 2-70 | ||

Headstock | Spindle speed | KW | 15 | 22 | 30 | ||

Spindle speed range | mm | 1000 | 1250 | 1600 | 2000 | 2500 | |

Main motor power | knm | 20 | 40 | ||||

Max.X Axis stroke | mm | 625 | 800 | 1000 | 1250 | 1500 | |

Max.Z Axis stroke | mm | 500 | 750 | 1000 | |||

Feed Data | Feed range of X Axis | mm/min |

| 1-200 | |||

Feed range of Z Axis | mm/min |

| 1-200 | ||||

Rapid moving range of X Axis | mm/min |

| 2000 | ||||

Rapid moving range of Z Axis | mm/min |

| 1500 | ||||

Other Data | Machine Length | mm | 3000 | 3500 | 3500 | 4500 | 4500 |

Machine Width | mm | 2000 | 2500 | 2800 | 3200 | 3500 | |

Machine Height | mm | 1500 | 1800 | 2000 | 2500 | 3000 | |

Control System |

| SIEMENS, FANUC, GSK,KND etc | |||||

Features

Electric servo bending machine realizes fast response and precise control through electric servo system, which improves productivity, reduces energy consumption, and lowers noise pollution. Its high-precision positioning capability ensures machining quality while reducing maintenance costs and enhancing the safety of the working environment.

- Conventional mechanical end face lathe spindle adopts double-row roller bearings, which makes the spindle have high rigidity and precision.

- The spindle speed is driven by AC frequency converter governor and the same service motor to realize stepless speed regulation of large transmission torque.

- The machine guideway adopts double/three-layer rectangular structure with large spacing and high degree, especially suitable for low-speed heavy-duty cutting.

- Intermittent centralized lubrication makes machine maintenance more convenient.

Applications

- The conventional end face lathe adopts mechatronic design with good flexibility, which is suitable for turning various tire molds, large disk parts, ring parts and so on. In addition, it can realize different machining processes such as inner hole, outer circle, end face, taper face, arc face, thread and so on. It is the ideal equipment for machining all kinds of tire molds, large flat disk-type parts and ring-type parts.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com