PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

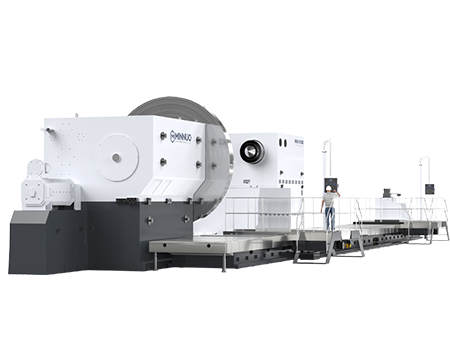

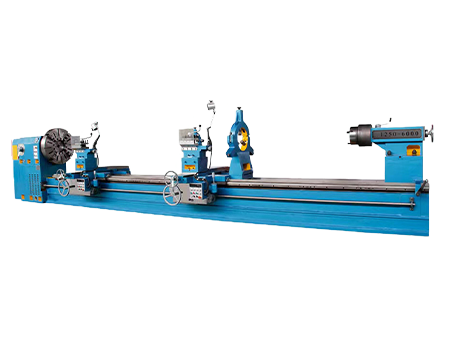

Conventional Mechanical Horizontal Lathe CX61 Series

Conventional mechanical horizontal lathe CX61 series are designed by international advanced computer technology and optimized finite element analysis method, so that the machine tool can carry the maximum load as far as possible, with reasonable design and exquisite material selection. All castings are made of high-strength dense baked cast iron, so that the whole machine tool has excellent rigidity, stability, accuracy retention, especially suitable for heavy cutting. It can mainly undertake all kinds of turning work, capable of turning the outer circle, end face, inner hole, grooving and other processes of all kinds of parts, and it is also suitable for hard alloy tools for powerful turning and processing of all kinds of ferrous and non-ferrous metals.

- Max.swing diameter over machine bed : 800/1250/1600/2000/2500mm

- Max.swing diameter over cutting tool carriage: 450/850/1250/1650/2050mm

- Max.work-piece weight: 2/6/15T

- Max.work-piece length: 1500-20000mm

Features

- All large castings are strictly annealed, plus aging treatment, completely eliminate internal stress, greatly improving the accuracy of the machine, the machined parts have excellent geometric accuracy, machine base for the cross-shaped structure, rectangular force design, organization, stability, reliability, and long retention.

- The bed guide rail adopts rectangular hard rail design, and the surface of the guide rail is processed by high-frequency and high precision surface grinding. The sliding surface is pasted with guide tape, which makes the surface of the guide rail smoother and more wear-resistant. The wider hard-rail design ensures to provide the machine with the required resistance and stability during heavy cutting.

- The spindle of the machine adopts triple bearing structure, which has good rigidity.

- The machine adopts side chip removal method, which is convenient for chip removal.

- The machine is also equipped with a separate oil pump for forced lubrication, as well as rapid traverse and terminal safety features.

- The speed, feed and power characteristics are reasonably designed and can well meet the needs of rough and finish machining.

Applications

- The conventional mechanical horizontal lathe CX61 series has large power, strong rigidity and wide range of spindle speed regulation, which is suitable for strong or high-speed cutting. it can turn end face, outer circle and inner hole, and can undertake drilling, nesting, boring and other processes.

Conventional Mechanical Horizontal Lathe CX61 Series | |||||||

| Model | Unit | CX6180 | CX61125 | CX61160 | CX61200 | CX61250 |

Machining Technical Parameters | Max.swing diameter over machine bed | mm | 800 | 1250 | 1600 | 2000 | 2500 |

Max.swing diameter over cutting tool carriage | mm | 450 | 850 | 1250 | 1650 | 2050 | |

Max.work-piece weight | T | 2 | 6 | 15 | |||

Max.work-piece length | mm | 1500-20000 | |||||

Machine Bed Parameters | Guide rail type | Rectangle | 2 guide rail | ||||

Guide rail width | mm | 600 | 755 | 1600 | 2000 | ||

Headstock | Spindle speed |

| Stepless variable frequency | ||||

Spindle speed range | r/min | 20-400 | 10-210 | 6-160 | 4-106 | ||

Main motor power | KW | 11 | 15 | 22 | 30 | ||

Centers | ° | 60 | |||||

Max.chuck diameter | mm | 500 | 800 | 1250 | 1600 | 2000 | |

Max. chuck torque | knm | 10 | 15 | 20 | 30 | ||

Feed Data | Max.X axis stroke | mm | 400 | 625 | 800 | 1000 | 1250 |

Max.Z axis stroke | mm | 1500-20000 | |||||

Feed range of X Axis | mm | 1-200 | |||||

Feed range of Z Axis | mm | 1-200 | |||||

Feed speed of X axis | mm/min |

|

| 3000 | |||

Feed speed of Z axis | mm/min |

|

| 2500 | |||

Tailstock | Diameter of tailstock sleeve | mm | 140 | 180 | 240 | 300 | |

Stroke of tailstock sleeve | mm | 300 | |||||

Taper of tailstock sleeve | ° | 60 | |||||

Rapid moving speed of tailstock | mm/min | Manually | 1500 | ||||

Other datas | Machine Length | mm | According to work-piece length | ||||

Machine Width | mm | 1500 | 2000 | 3500 | 3800 | 4000 | |

Machine Height | mm | 1400 | 1800 | 2300 | 2600 | 3000 | |

Control system |

| Semi-automatic | |||||

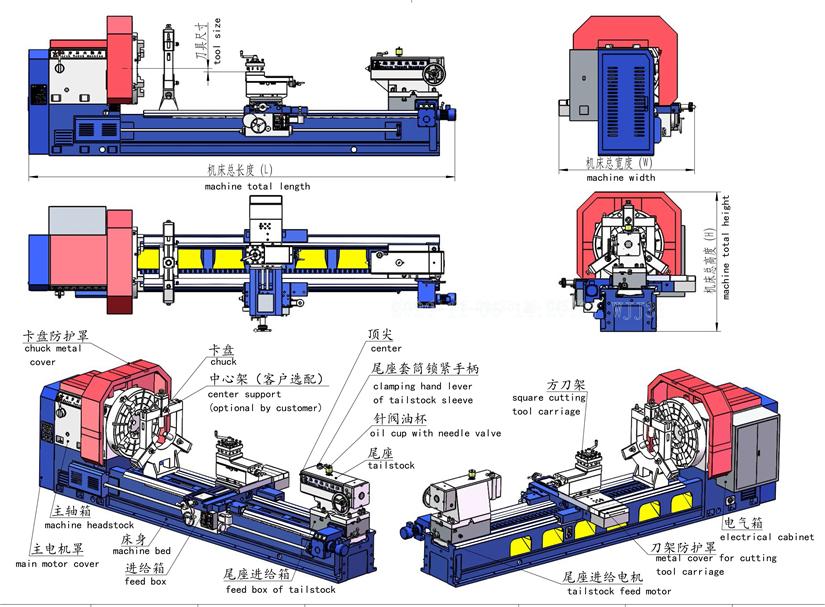

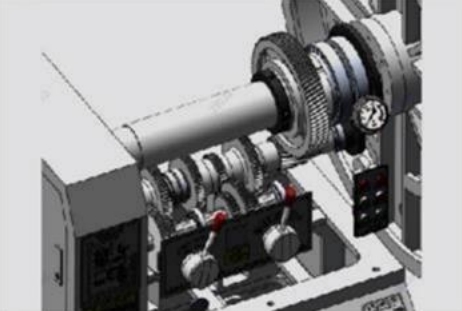

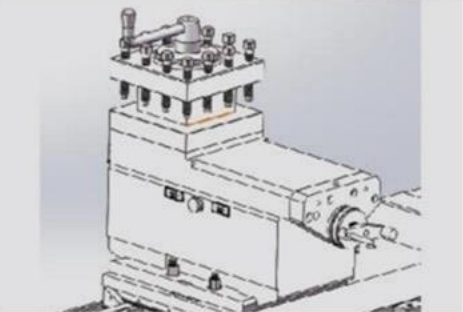

The above picture presents the internal structure of the CNC face lathe CX61 series machine and related details, if there is something you don’t understand you can contact us, our engineers will do one-to-one communication with you.

Tail-stock 2 gear shifts variable speeds +rotary spindle

Built-in rotary spindle design for the tail-stock,the main shaft is installed in the rotary bearing with high rotation accuracy. The tail-stock is 2gear shifts variable speeds design .The sleeve movement can realize quick and slow speeds with arbitrary switching according to operation demands.

Integrated electrical movement control of tail-stock

The overall design of upper and bottom parts oft ail-stock is electrical control. The gear meshing rack is driven by the motor to reduce the output of manual operation and improve the production efficiency.

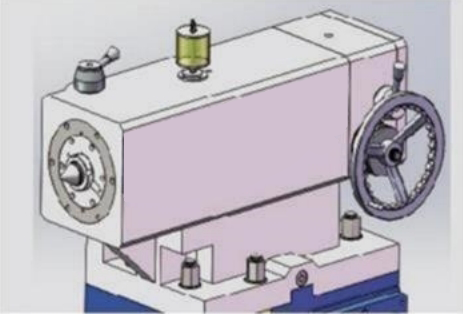

High accuracy head-stock

40Cr forged and ground gears are used in the head stock with 4 gear shifts speed regulation.All shafts are spline structure with tight fit. The standard configuration of bearings are brands with high accuracy.The gear meshes with high accuracy and low noise.

Heavy duty cutting tool carriage

The machine is equipped with heavy duty cutting tool carriage. Relying on the variable speed mechanism of sliding box to control both X & Z axis and fast & slow movement of tool carriage by frequency conversion. The vertical turret with 4 positions can realize +/-90rotation.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com