PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

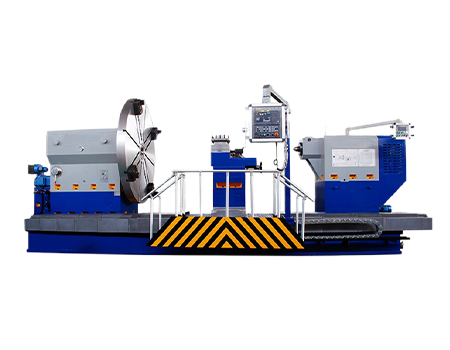

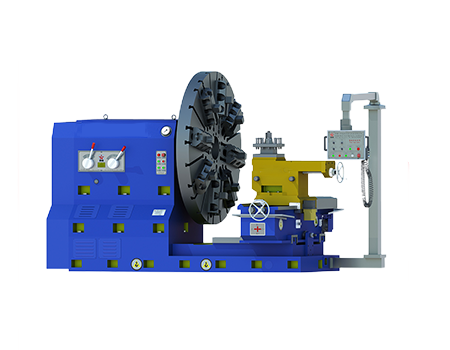

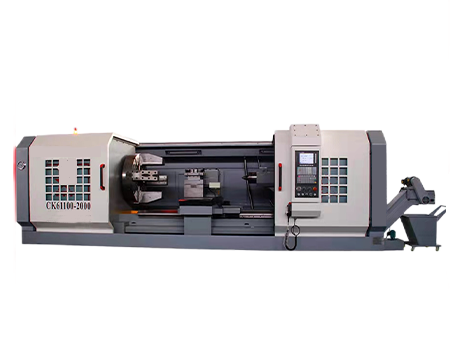

Digital Display Heavy Horizontal Lathe CX61 Series

The digital display heavy duty horizontal lathe is automaticaly controlled by the digital display integrated control system.Through PLC contact command, the lathe can realize various turning process for internal holes, outer circle, part body,conical surface and arc surface. The cutting instructions of the lathe machine abandon the traditional button-type control command and realize the all kinds of operations by jogging control function on the touch screen. The touch screen can realize simple programming and operation instructions.

- Max.swing diameter over machine bed : 1600/2000/2500/3150mm

- Max.swing diameter over cutting tool carriage: 1250/1650/2050/2650mm

- Max.work-piece weight: 32/63T

- Max.work-piece length: 4000-20000mm

Digital Display Heavy Horizontal Lathe CX61 Series | ||||||

| Model | Unit | CX61160 | CX61200 | CX61250 | CX61315 |

Machining Technical Parameters | Max.swing diameter over machine bed | mm | 1600 | 2000 | 2500 | 3150 |

Max.swing diameter over cutting tool carriage | mm | 1250 | 1650 | 2050 | 2650 | |

Max.work-piece weight | T | 32 | 63 | |||

Max.work-piece length | mm | 4000-20000 | ||||

Machine Bed Parameters | Guide rail type | Rectangle | 4 guide rails | |||

Guide rail width | mm | 1600 | 2000 | |||

Head stock | Spindle speed |

| Step-less variable frequency | |||

Spindle speed range | r/min | 1-100 | 1-100 | 1-100 | 0.5-80 | |

Main motor power | KW | 45 | 55 | 75 | 90 | |

Centers | ° | 75 | ||||

Max.chuck diameter | mm | 1400 | 1600 | 2000 | 2500 | |

Max. chuck torque | knm | 80 | 120 | |||

Feed Data | Max.X axis stroke | mm | 800 | 1000 | 1250 | 1575 |

Max.Z axis stroke | mm | 4000-20000 | ||||

Feed range of X Axis | mm | 1-200 | ||||

Feed range of Z Axis | mm | 1-200 | ||||

Rapid moving speed of X axis | mm/min | 3000 | ||||

Rapid moving speed of Z axis | mm/min | 2500 | ||||

Tail stock | Diameter of tail stock sleeve | mm | 300 | 420 | ||

Stroke of tail stock sleeve | mm | 300 | ||||

Taper of tail stock sleeve | ° | 75 | ||||

Rapid moving speed of tail stock | mm/min | 1500 | ||||

Other datas | Machine Length | mm | Depends on the work-piece length | |||

Machine Width | mm | 3500 | 3800 | 4000 | 4200 | |

Machine Height | mm | 2300 | 2600 | 3000 | 3500 | |

Control system |

| Touch Operation Panel | ||||

Features

Digital display heavy horizontal lathe CX61 series heavy-duty horizontal lathe adopts the international advanced design means and manufacturing technology, carefully designed a set of electrical, automatic control, hydraulic control and modern mechanical design and other multidisciplinary, multi-disciplinary precision manufacturing technology as one of the electromechanical integration machine tool products. The structure and performance of the machine tool is applicable, and the machine tool is characterized by high dynamic and static rigidity, long service life, high processing efficiency, safe and reliable functions, convenient operation and beautiful modeling.

- The main drive and feed drive adopt separate structure, the main drive is driven by DC motor, and the speed range of spindle is realized by mechanical three-speed gear change.

- The bed adopts integral three guide rails, and the bed guide rail adopts low friction vice sliding flat guide rail with grinding processing or inlaid steel structure.

- The spindle box spindle is of through-axis structure, adopting high-precision adjustable radial clearance double-row short cylindrical roller bearings, and the optimized design adopts a larger spindle diameter and the best support span, which improves the rotary accuracy and dynamic and static rigidity of the spindle. The top of the spindle adopts flange type short taper structure, which improves the rigidity of the connection between the top of the spindle and the spindle.

- The tool holder adopts trapezoidal screw or ball screw in the transverse direction, and adopts high-precision rack and double tooth bar backlash structure in the longitudinal direction, which improves the transmission precision of the tool holder.

- The tailstock is a whole box structure, the mandrel in the sleeve adopts double-row short cylindrical roller bearing with high precision adjustable radial clearance, the top is flanged short tapered shank top, which makes the tailstock have high rigidity, the sleeve and tailstock are motorized and equipped with hydraulic force measuring device.

- Double tool holders, milling and boring devices, grinding devices, coolant devices, etc. can be provided according to user requirements.

Applications

- The digital display heavy duty horizontal lathe is suitable for high-speed steel, carbide steel and other tools, for ferrous metals, non-ferrous metals and some non-metallic shafts, cylinders and disks, turning cylindrical, end face, groove cutting, cutting off, boring and so on.

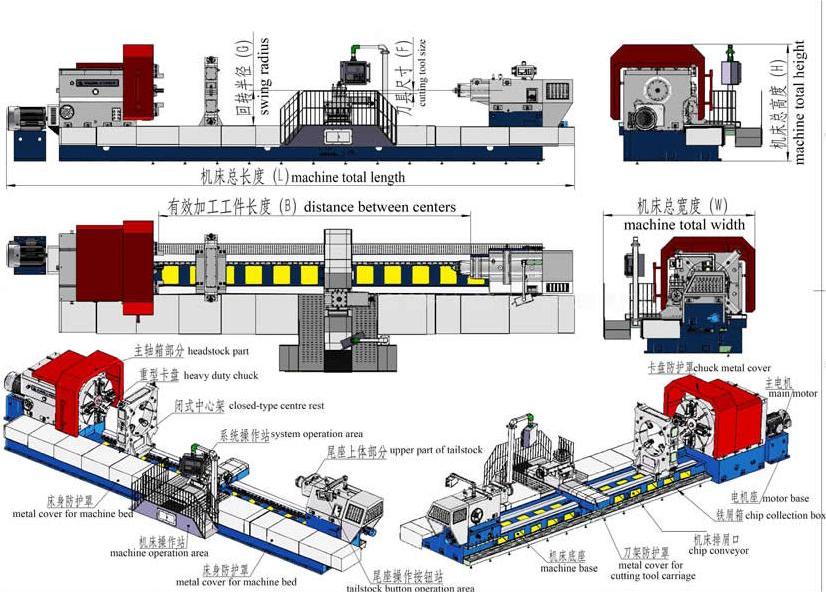

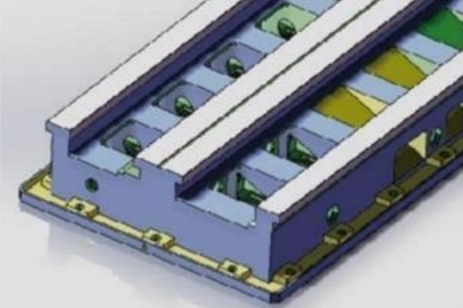

The above picture presents the internal structure of the digital display heavy horizontal lathe CX61 series machine and related details, if there is something you don’t understand you can contact us, our engineers will do one-to-one communication with you.

Integrated operation station of tool carriage

This lathe is installed an integrated operation station of tool carriage for the operator.Dual-layer barrier is mounted around the worktable to prevent the operator falling accident from the high place and keep the operator safe. There is tool collection box in the front of worktable used for placing machine tools and operation manual documents.

Backlash gearbox with double set of teeth:

My company designed a transmission structure of backlash gearbox with double set of teeth.By two sets worm and worm wheel mechanism,that a worm meshes with a worm gear to realize the transmission.This structure effectively replaces the transmission mechanism of traditional lead screw that avoid the droop phenomenon if the screw is too long. This structure is not affected by the work-piece length and meet with the request of long-shaft turning lathe machine.

4 guide rails of machine bed base + lateral chip removal + water circulation:

The machine bed is a kind of 4 guide rails structure to meet with heavy cutting request.The machine base adopts lateral chip removal structure with 45 ° angle of inclination, which is very convenient to collect the iron chips. The 4sides of machine base are one-piece castings with recycling tank for recycling the cooling water and grease oil.

Integrated operation station:

The integrated operation button station of machine has beautiful layout and comprehensive function. All operation buttons +manual pulse generator+ touching operation panel with convenient and sensitive operation can perfectly replace the traditional mechanical control mode to realize semi-automatic programming control of mechanical lathe machine.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com