PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

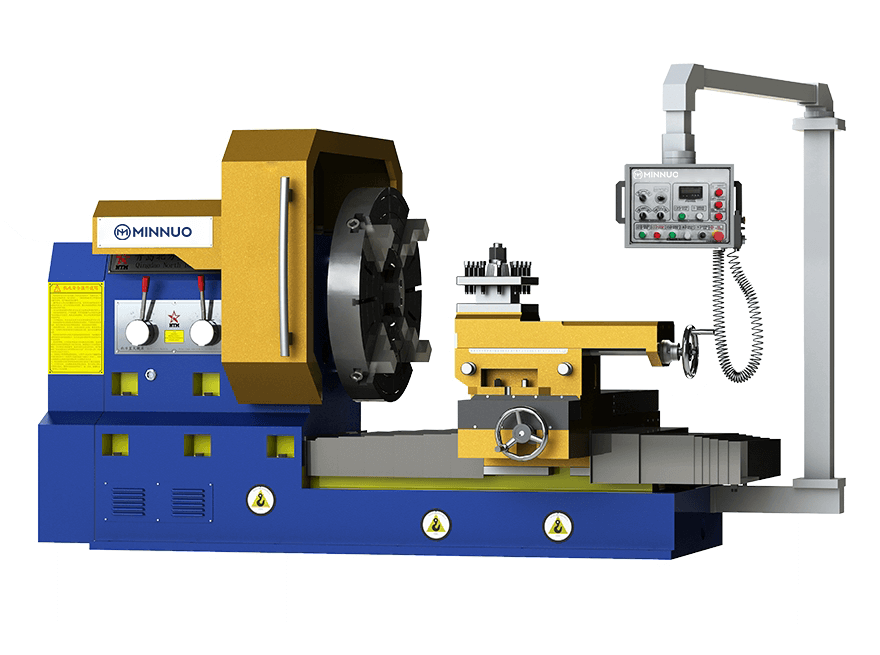

Flange Lathe Machine Floor Type CX60 Series

Flange turning lathe is also known as big head lathe, disc lathe and pit lathe. Minnuo produces flange lathe machinery floor-type CX60 series, the machine tool has large loading capacity, strong rigidity, beautiful appearance, easy to operate, can process all kinds of internal and external cylindrical surfaces, end surfaces, arc surfaces and other molding surface parts, it is the ideal equipment for processing all kinds of wheels, tires, and large-scale flat plate and ring parts. Floor-type lathe is mainly used for processing large and heavy mechanical parts, such as tire molds, large diameter flange tube plate, turbine parts, sealing head, etc. It is widely used in petrochemical industry, heavy machinery, automobile manufacturing, mining, railroad equipment and aviation parts processing and manufacturing.

- Max.swing diameter over machine bed : 1600/2000/2500/3000mm

- Max.swing diameter over cutting tool carriage: 1250/1600/2000/2500mm

- Max.work-piece weight: 2/3T

- Max.work-piece length: 500/750mm

Features

The mechanical floor type of flange lathe can be displayed by LED digital display, and the spindle speed can be realized by wave switch to achieve 20 levels of infinite speed regulation within the block, which can satisfy the machining needs of different workpieces for different spindle speeds, and realize the individual action commands.

- Flange lathe CX60 series base guideway adopts rectangular structure with large span and high rigidity, suitable for low-speed heavy-duty turning.

- The operation desk is installed on the word position of the machine tool, which is easy to operate and the coordinate display is clear.

- The structure of floor-type flange lathe adopts bed guideway, and the spindle box spindle is perpendicular to the supporting plate.

- The spindle box and horizontal bed are a single unit attached to the same machine base. The machine base is a mountain-shaped guideway structure that can be manually adjusted for horizontal movement. Clearances in the machine tool castings can be eliminated by vibratory movements.

Applications

- Flange lathe is suitable for manufacturing parts such as flange, bearing seat, etc. The machining range is relatively small, and the process precision is high, meanwhile, it is less affected by the mechanical stiffness, and can realize high machining precision.

- This flange lathe can be used to turn disk workpieces within the range of 1250mm-2500mm in diameter, such as tire molds, large-diameter flange pipe plates, turbine fittings, head end caps, etc. It is widely used in the processing and manufacturing of petrochemical industry, heavy machinery, automobile manufacturing, mining and railroad equipments as well as aeronautical components.

Flange Lathe Machine Floor Type CX60 Series | ||||||

| Model | Unit | CX6016 | CX6020 | CX6025 | CX6030 |

Machining Technical Parameters | Max.swing diameter over machine bed | mm | 1600 | 2000 | 2500 | 3000 |

Max.swing diameter over cutting tool carriage | mm | 1250 | 1600 | 2000 | 2500 | |

Max.work-piece weight | T | 2T | 3T | |||

Max.work-piece length | mm | 500 | 750 | |||

Machine Bed Parameters | Guide rail type |

| Stepless variable frequency | |||

Guide rail width | r/min | 10-156 | 4-106 | |||

Headstock | Spindle speed | KW | 15 | 18.5 | 22 | |

Spindle speed range | mm | 1250 | 1600 | 2000 | 2500 | |

Main motor power | knm | 20 | 40 | |||

Max.X Axis stroke | mm | 800 | 1000 | 1250 | 1575 | |

Max.Z Axis stroke | mm | 500 | 750 | |||

Feed Data | Feed range of X Axis | mm/min | 1-200 | |||

Feed range of Z Axis | mm/min | 1-200 | ||||

Rapid moving range of X Axis | mm/min | 2000 | ||||

Rapid moving range of Z Axis | mm/min | 1500 | ||||

Other Data | Machine Length | mm | 3500 | 3500 | 4500 | 4500 |

Machine Width | mm | 2500 | 2800 | 3200 | 3500 | |

Machine Height | mm | 1800 | 2000 | 2500 | 3000 | |

Control System |

| Semi-automatic | ||||

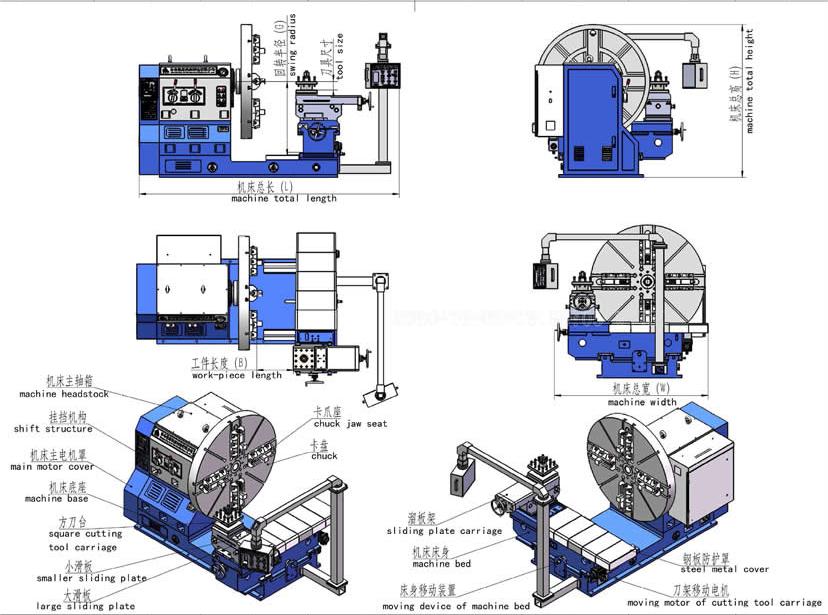

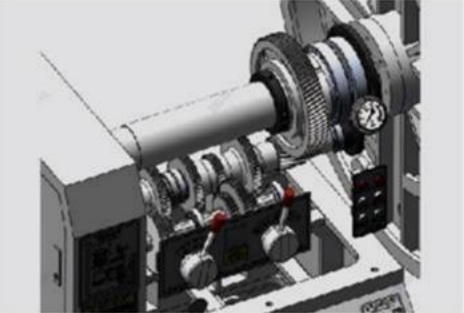

The above picture presents the internal structure of the flange lathe machine floor type CX60 series machine and related details, if there is something you don’t understand you can contact us, our engineers will do one-to-one communication with you.

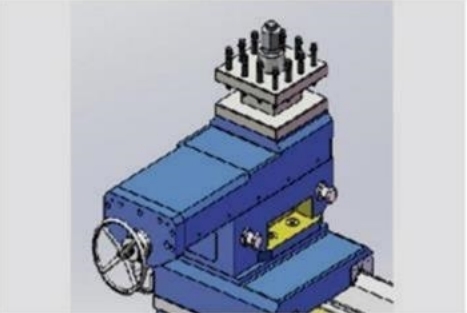

New Designed cutting tool carriage

New designed heavy duty cutting tool carriage structure. The layout of each layer of cutting tool carriage is uniformed and reasonable. The smaller sliding plate can realize +/- 90 °rotation with automatic feed function. During machining process, it has advantages of large cutting volume, high accuracy,simple operation and high stability.

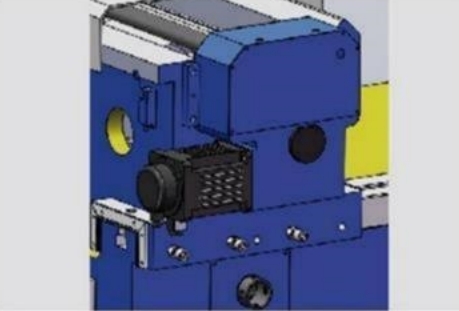

Servo feed mechanism

Both X and Z axis are controlled by servomotor with 20 gear shifts variable speeds. Dual axis electromagnetic pull-in with free switching,accuracy cutting, large torque and high accuracy control.

High accuracy head-stock

40Cr forged and ground gears are used in the headstock with 4 gear shifts speed regulation.All shafts are spline structure with tight fit. High-precision slewing bearings are standard. The gear meshes with high accuracy and low noise.

Integrated operation station

The integrated operation button station of machine has beautiful layout and comprehensive function. All operation buttons, manual pulse generator, touching operation panel with convenient and sensitive operation can perfectly replace the traditional mechanical control mode to realize semi-automatic programming control of mechanical lathe machine.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com