PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

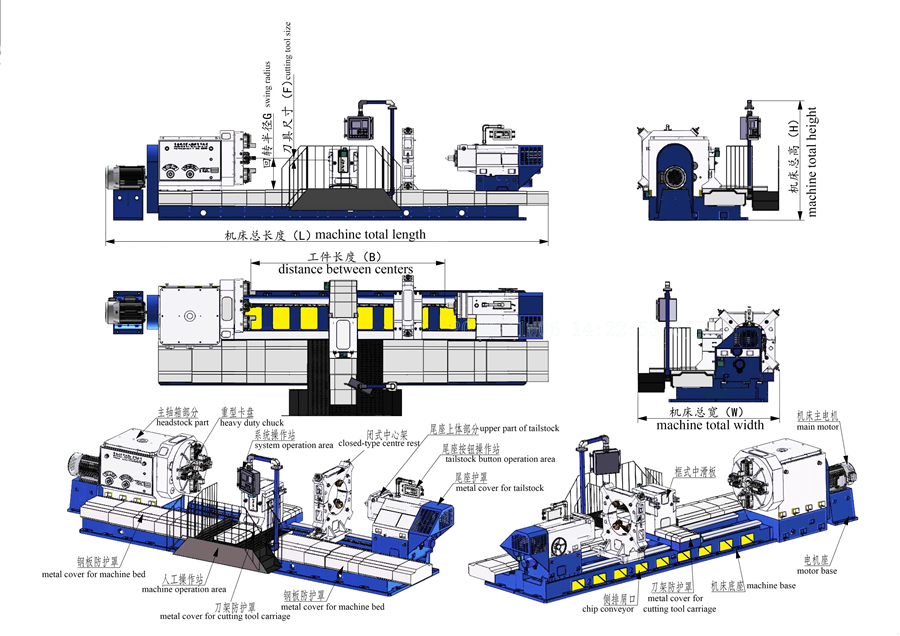

Heavy Duty CNC Roll Lathe CK84 Series

Heavy duty CNC roll lathe CK84 series is suitable for rough and finish machining of cast iron, steel and non-ferrous metal rolls, capable of turning and repairing external rounds, end faces and complex profiles. Equipped with high-speed steel and other cutting tools, the spindle three-support structure ensures rigidity, and the side chip removal system facilitates chip removal and other advantages. Reasonable design of speed, feed and power characteristics to meet the processing needs, the machine is characterized by high efficiency, energy saving, safety, easy to operate and beautiful.

- Max.swing diameter over machine bed : 800/1000/1250/1400mm

- Max.swing diameter over cutting tool carriage: 650/800/1000/1250mm

- Max.work-piece weight: 6/15/25/32T

- Max.work-piece length: 2500-6000mm

Features

- The spindle of the machine adopts a three-support structure with good rigidity.

- Adopting side chip discharge method, the chip discharge is convenient.

- The machine tool also has a separate oil pump for forced lubrication, as well as rapid movement and terminal insurance.

- The tailstock moving adopts motorized moving suit.

- The speed, feed and power characteristics are reasonably designed to meet the needs of rough and finish machining.

Applications

- Heavy duty CNC roll lathe CK84 series is mainly used for cast iron, steel and non-ferrous metal roll rough turning and finish turning processing, the use of high-speed steel, hardened gold or other materials of the tool can be carried out on the outer circle of the roll, the end face and a variety of complex holes and surfaces of the turning process and repair processing.

- It is widely used in high-precision metal processing in automobile manufacturing, machine tool manufacturing, shipbuilding, petroleum and chemical industries.

Heavy Duty CNC Roll Lathe CK84 Series | ||||||

| Model | Unit | CK8465 | CK8480 | CK84100 | CK84125 |

Machining Technical Parameters | Max.swing diameter over machine bed | mm | 800 | 1000 | 1250 | 1400 |

Max.swing diameter over cutting tool carriage | mm | 650 | 800 | 1000 | 1250 | |

Max.work-piece weight | T | 6 | 15 | 25 | 32 | |

Max.work-piece length | mm | 2500-6000 | ||||

Machine Bed Parameters | Guide rail type | Rectangle | 4 guide rails | |||

Guide rail width | mm | 1000 | 1250 | 1400 | 1600 | |

Headstock | Spindle speed |

| Stepless variable frequency | |||

Spindle speed range | r/min | 1-160 | 1-160 | 0.5-100 | 0.5-100 | |

Main motor power | KW | 30 | 37 | 45 | 75 | |

Centers | ° | 60 | 75 | |||

Max.chuck diameter | mm | 600 | 800 | 1000 | 1250 | |

Max. chuck torque | knm | 80 | 120 | |||

Feed Data | Max.X axis stroke | mm | 300 | 400 | 400 | 500 |

Max.Z axis stroke | mm | 2500-6000 | ||||

Feed range of X Axis | mm | 1-200 | ||||

Feed range of Z Axis | mm | 1-200 | ||||

Feed speed of X axis | mm/min | 3000 | ||||

Feed speed of Z axis | mm/min | 2500 | ||||

Tailstock | Diameter of tailstock sleeve | mm | 180 | 180 | 240 | 300 |

Stroke of tailstock sleeve | mm | 300 | ||||

Taper of tailstock sleeve | ° | 60 | 75 | |||

Rapid moving speed of tailstock | mm/min | 1500 | ||||

Other datas | Machine Length | mm | Depends on the work-piece length | |||

Machine Width | mm | 2000 | 2500 | 3000 | 3500 | |

Machine Height | mm | 1500 | 1800 | 2000 | 2200 | |

Control system |

| SIEMENS, FANUC, GSK,KND etc | ||||

The above picture presents the internal structure of the heavy duty CNC roll lathe CK84 series machine and related details, if there is something you don’t understand you can contact us, our engineers will do one-to-one communication with you.

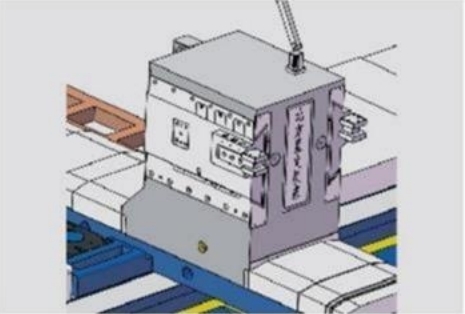

Independent electrical cabinet

The heavy duty horizontal lathe machine is designed a kind of separate electrical cabinet with 2 ways and 4 doors, which has a complete electrical interlocking and power-off leakage protection device. The electrical cabinet is installed a separate air-conditioning heat dissipation device to guarantee the safety and effective power supply of lathe machine.

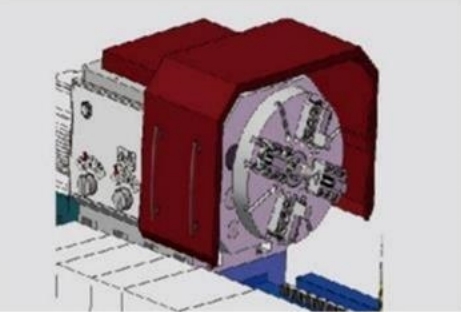

Double square type cutting tool carriage

The lathe is installed double square type cutting tool carriage.During the machining process,both sides of cutting plates can realize machining process at the same time with high effciency. The universal tool mounted on the front side can meet with different machining processes of work-piece.

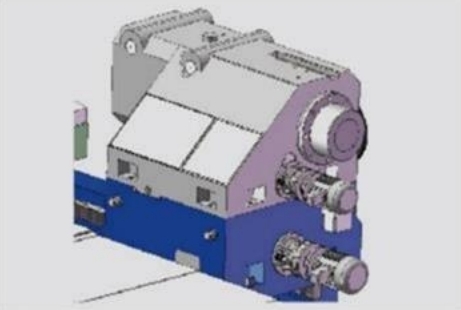

Protection device of machine rotation part

The pull & push device is installed on the machine rotation part (such as chuck and motor) to prevent the fall off of work piece due to centrifugal force,and ensure the machine and operator’s safety.This design meets with safety standard of machine design.

Electrical movement of tail-stock upper part & bottom part +dual clamping of tail-stock sleeve

The upper and bottom parts of tail-stock are all electrical control to realize the movement in both quick and low speeds. Meanwhile, it has function of clutch overload protection, The tail-stock sleeve adopts dual circular arc clamping structure to ensure the camping force.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com