PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

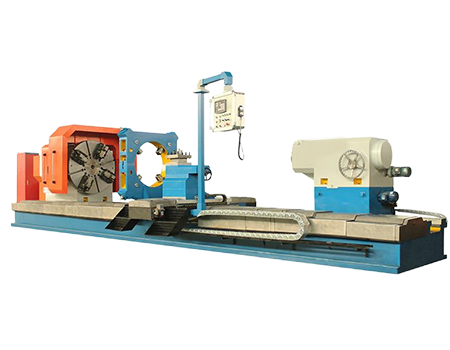

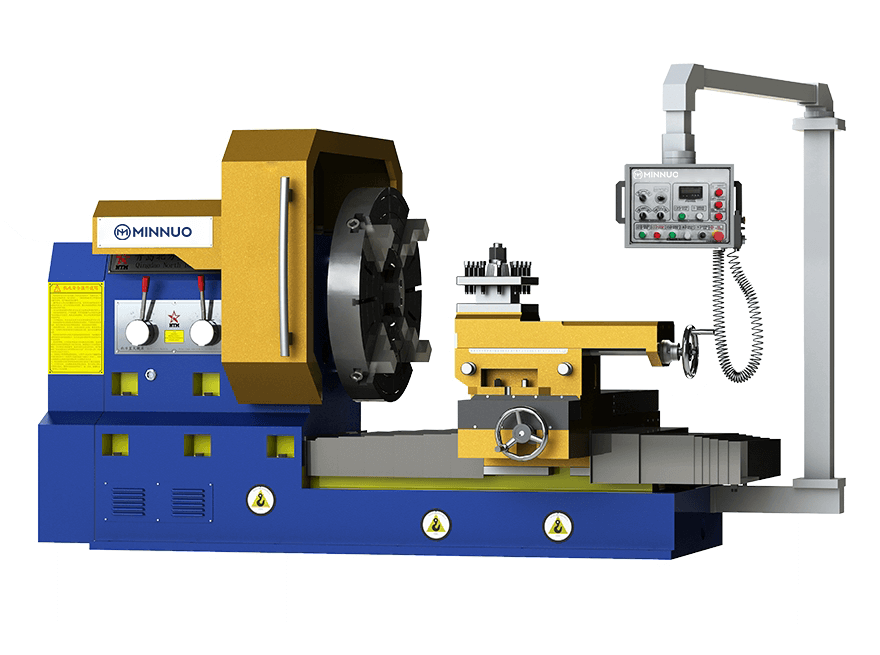

Heavy Duty Horizontal Lathe CK61 Series

The CNC heavy-duty horizontal lathe CK61 series produced by Minnuo is suitable for machining workpieces made of high-speed steel, carbide steel and other materials, and turning outer circle, end face, grooving, cutting, boring, threading, curved surfaces and conical surfaces of ferrous, non-ferrous and partially non-metallic shafts, rolls and discs, and other processes.

- Max.swing diameter over machine bed : 1600/2000/2500/3150mm

- Max.swing diameter over cutting tool carriage: 1250/1650/2050/2650mm

- Max.work-piece weight:32/63T

- Max.work-piece length: 4000-20000mm

Features

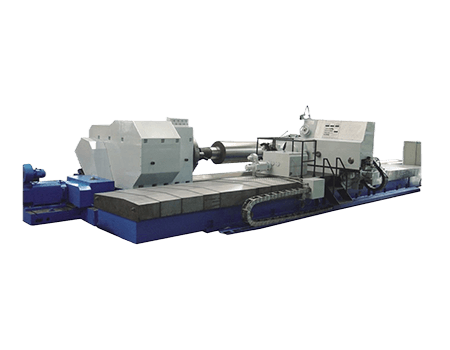

- The CNC heavy-duty horizontal lathe CK61 series produced by Minnuo, the machine bed adopts the whole three guide rails, the drag plate and the bed guide rail adopts the paste moulding structure, the telescopic steel plate shield is fully closed for protection, the machine tool adopts the downward chip-removal method, which is convenient for chip-removal, and the tool carrier transversely adopts the ball screw, and longitudinally adopts the high-precision tooth rack and double-tooth bar backlash structure, which improves the transmission precision of the tool carrier.

- The machine also has a separate oil pump for forced lubrication, as well as rapid movement, terminal insurance and other functions. The speed, feed and power characteristics are reasonably designed to meet the needs of rough and finish machining of a wide range of parts.

Applications

- Heavy Duty Horizontal Lathe CK61 Series through the automatic control of CNC system (FANUC/Siemens/GSK/KND, etc.), can be used for turning various kinds of inner hole, outer circle, conical surface, circular arc surface and thread.

- It is suitable for machining shaft parts and disc parts.it is widely used in steel, paper industry and maintenance of large equipment.

Heavy Duty Horizontal Lathe CK61 Series | ||||||

| Model | Unit | CK61160 | CK61200 | CK61250 | CK61315 |

Machining Technical Parameters | Max.swing diameter over machine bed | mm | 1600 | 2000 | 2500 | 3150 |

Max.swing diameter over cutting tool carriage | mm | 1250 | 1650 | 2050 | 2650 | |

Max.work-piece weight | T | 32 | 63 | |||

Max.work-piece length | mm | 4000-20000 | ||||

Machine Bed Parameters | Guide rail type | Rectangle | 4 guide rails | |||

Guide rail width | mm | 1600 | 2000 | |||

Headstock | Spindle speed |

| Stepless variable frequency | |||

Spindle speed range | r/min | 1-100 | 1-100 | 1-100 | 1-100 | |

Main motor power | KW | 45 | 55 | 75 | 90 | |

Centers | ° | 75 | ||||

Max.chuck diameter | mm | 1400 | 1600 | 2000 | 2500 | |

Max. chuck torque | knm | 80 | 120 | |||

Feed Data | Max.X axis stroke | mm | 800 | 1000 | 1250 | 1575 |

Max.Z axis stroke | mm | 4000-20000 | ||||

Feed range of X Axis | mm | 1-200 | ||||

Feed range of Z Axis | mm | 1-200 | ||||

Feed speed of X axis | mm/min | 3000 | ||||

Feed speed of Z axis | mm/min | 2500 | ||||

Tailstock | Diameter of tailstock sleeve | mm | 300 | 420 | ||

Stroke of tailstock sleeve | mm | 300 | ||||

Taper of tailstock sleeve | ° | 75 | ||||

Rapid moving speed of tailstock | mm/min | 1500 | ||||

Other datas | Machine Length | mm | Depends on the work-piece length | |||

Machine Width | mm | 3500 | 3800 | 4000 | 4200 | |

Machine Height | mm | 2300 | 2600 | 3000 | 3500 | |

Control system |

| SIEMENS, FANUC, GSK, etc | ||||

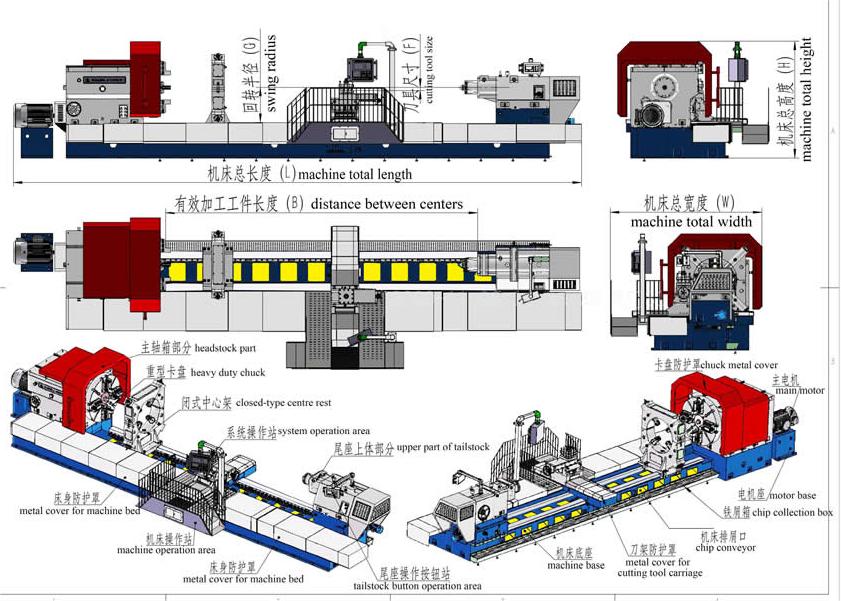

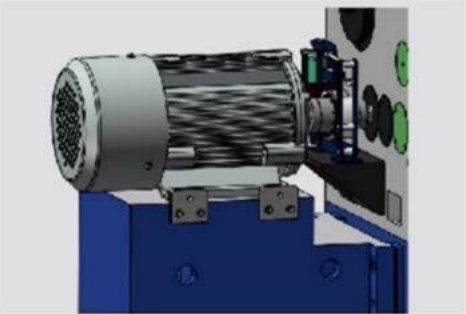

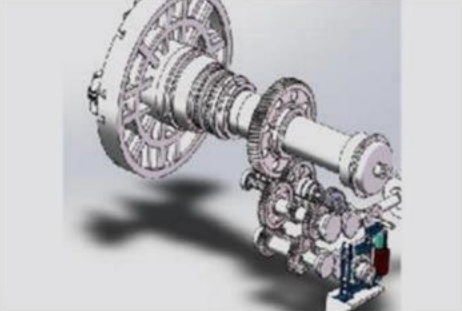

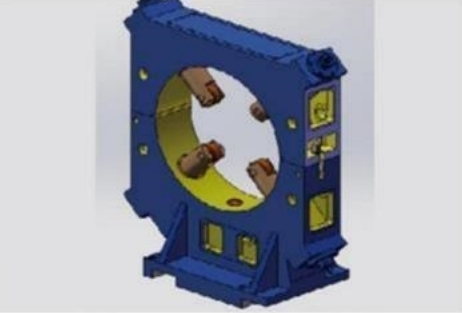

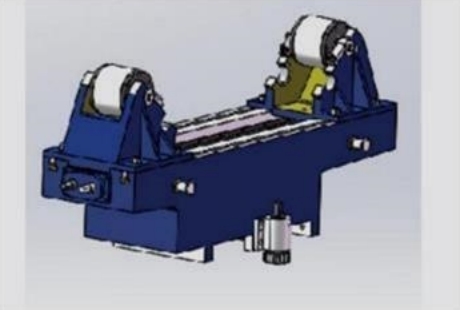

The above picture presents the internal structure of the heavy duty horizontal lathe CK61 series machine and related details, if there is something you don’t understand you can contact us, our engineers will do one-to-one communication with you.

Main motor directly coupling with head-stock

The main motor is directly connected with variable-speed shaft by the elastic coupler, which can effectively avoid the power loss caused by the structure of traditional and synchronous belts,and ensure the output torque of spindle gear box and power output of machine.

High accuracy head-stock

The internal gears in the head-stock are all 40Crforged gears with ground teeth. Shafts are spline structure with tight fit, high accuracy and low noise.The head-stock is lubricated automatically by the oil pump unit.The spindle adopts the principle of 4 points unloading support to guarantee the head-stock stability.

Closed-type roll rest with 4 columns

The machine is equipped with a heavy closed-type roll rest with 4 columns. The bearing-roller type support roller can realize high strong support for different irregular work-pieces.The 4 columns can be adjusted separately by the screw. This roll rest is positioning by dual flat guide rails with large contact surface, high positioning accuracy, high stability and strong support force.

Open-type center rest

The open-type center rest is used for reducing the deformation of head-stock and tail-stock main shafts during heavy cutting process or replacing the tail-stock when the center is not suitable for machining the long work-piece.Dual rotation roller sleeve can be adjusted separately to meet with the support demands of different diameter work-pieces.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com