PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

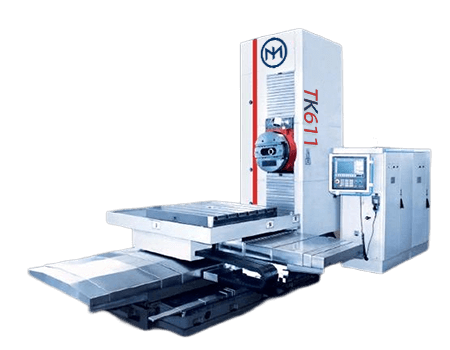

CNC Horizontal Boring and Milling Machine TK611 Series

CNC Horizontal Milling and Boring Machine TK611 series is a high-performance machine tool characterized by high torque, high rigidity and high efficiency. Equipped with rotary table and cross slide structure, the machine is capable of realizing a variety of machining processes such as boring, milling, drilling, reaming, etc. It is especially suitable for the machining of complex parts with multiple hole systems and precise hole spacing requirements. It also supports six-axis control and four-axis linkage, and is capable of arc interpolation and three-dimensional surface machining, making it a versatile and powerful universal machine tool in the field of machining.

- Table size: 1400×1600mm

- Spindle dia.: φ130mm

- X/Y/Z Travel: 2000/2000/2000mm

- Table loading: 8T

Program | Unit | TK6111 | TK6113 | ||

Table size | mm | 1250×1400 | 1400×1600 | ||

Spindle dia. | mm | φ110 | φ130 | ||

X Travel | mm | 1800-2000 | 1800-2000 | ||

Y Travel | mm | 1200-1600 | 1600-2000 | ||

Z Travel | mm | 1200-1600 | 1200-2000 | ||

W Travel | mm | 600 | 800 | ||

B Travel |

| CNC rotary | CNC rotary | ||

T slot | mm | 22×125 | 22×125 | ||

Table loading | T | 5 | 8 | ||

CNC controller |

| SIEMENS B28D or FANUC OI MD | |||

Axis quantity |

| X/Y/Z/W(U) | X/Y/Z/W(U) | ||

Spindle taper |

| BT50(P50T-1) | |||

Spindle speed | rpm | 2-2000 | 2-2000rpm | ||

Main motor power δ torque | kw | 18kw( 1300Nm) | 30kw(2200Nm) | ||

Max. boring/drilling dia. | mm | φ240/250 | φ300/80 | ||

Max. axial feeding force on spindle | mm/min | 13000 | 23000 | ||

X/Y/Z Rapid traverse | mm/min | 3000 | 3000 | ||

X/Y/Z Feeding Speed | mm/min | 5-1000 | 5-2000 | ||

W axis Feeding speed | mm/min | 0.5-1000 | 5-2000 | ||

W axis Rapid traverse | mm/min | 2000 | 2000 | ||

Radial stroke of facing head tool holder | mm | 160 | 200 | ||

Facinghead speed | rpm | 4-125 | 2-125 | ||

Max. Machining dia. of facing head tool holder | mm | φ630(Optional) | φ800(Optional) | ||

Max. permitted torque of facing head | Nm | 1300(Optional) | 2600(Optional) | ||

Feeding speed of facing head | mm/min | 0.2-500(Optional) | 0.2-500(Optional) | ||

Rapid traverse of facing head tool holder | mm/min | 1000(Optional ) | 1000(Optional) | ||

X/Y/Z (GB/T17421.2-2000) Positioning accuracy | mm | 0.026/0.03/0.03 | 0.03/0.03/0.03 | 0.04/0.03/0.03 | 0.03/0.03/0.03 |

W axis( GB/T17421.2-2000) Positioning accuracy | mm |

| 0.03 | ||

B axis Positioning accuracy |

| 0.08 | |||

X/Y/Z/W (GB/T17421.2-2000) Repeated accuracy | mm | 0.015/0.015/0.015 | 0.015/0.015/0.015/0.015 | ||

B axis Repeated accuracy |

| 4*90°±6″ | |||

Machine sizes | m | 6.3×3.9×3.7 | 6.5×4.2×3.9 | ||

Machine weight | T | 25 | 32 | ||

Features

- The whole machine adopts six-axis four linkage automatic numerical control (the system can choose Siemens and Fanuc), X, Y, Z are driven by servo motors ball screw rotation, well-known brands of linear guide, high geometric accuracy, long service life.

- The bed and table support use linear guide.

- Boring axis is equipped with hydraulic loose pulling tool mechanism, loading and unloading tool is convenient and fast, improve work efficiency.

- The rotary table can be selected as high-precision arbitrary indexing 4 X 90° positioning rotary table (manual rotation, 90° positioning, hydraulic locking).

- The rotary contact surface adopts rolling structure, and the use of advanced backlash gear box double gear output drives the rotation of large gear ring, so that the rotary light and flexible, high precision.

- The table rotary adopts hydraulic locking and loosening, with large locking torque and good dynamic response, and is equipped with cooling and water return device.

Applications

- TK611 series CNC horizontal boring and milling machine can process plane milling, hole machining, curved surface milling, as well as milling, drilling, boring, reaming, tapping and countersinking, etc., which is the necessary choice for large parts machining and mass production.

Machine environment

- Power supply: 3AC 380V+10% 50HZ±1HZ

- Altitude:s1500m

- Temperature:5~45

- Relative humidity:<85%

- Environment: no harmful and corrosive gases, liquidsdust; No strong vibration, strong magnetic field, strong

Related Products

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com