PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

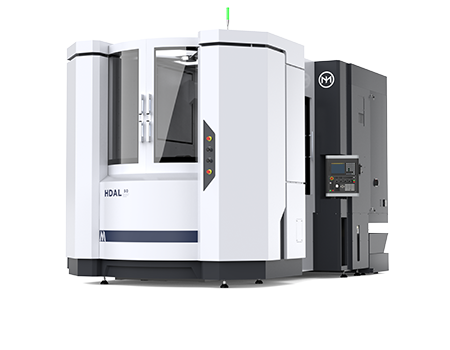

High Precision Horizontal Machining Center HDAL Series

HDAL series horizontal machining center is a new generation of CNC machine tool with high stability, precision ball screw drive, equipped with fast automatic tool changer system and advanced CNC system, which is specially designed to improve the efficiency and precision of complex parts machining in automobile, mold and machinery manufacturing industries.

- Table size: 630*630mm

- Table maximum load: 1300kg

- X/Y/Z axis travel: 900/800/800mm

- Max.work-piece length: 500/750mm

Specifications | Unit | HDAL50 | HDAL63 | |

Table size | mm | 500×500 | 630×630 | |

Max table load | kg | 800 | 1300 | |

Table indexing | ° | 1°×360° | 1°×360° | |

Travel: X/Y/Z | mm | 700/650/650 | 900/800/800 | |

Max rapid traverse: X/Y/Z | m/min | 36/30/36 | 36/30/36 | |

Spindle speed | rpm | 6000 | 4000 | |

Tool magazine |

| BT40 | OP: BT50 | BT50 |

Tool capacity |

| 24 | 24 | 24 |

Tool change time | s | 4(Tool-Tool) | 5(Tool-Tool) | 5(Tool-Tool) |

Max. tool weight | kg | 8 | 18 | 18 |

Max. tool diameter | mm | φ75/φ150 | φ110/φ220 | φ110/φ220 |

Max. tool length | mm | 300 | 400 | 400 |

Net. weight | kg | 8500 | 9000 | 11500 |

Machine dimensions(L*W*H) | mm | 3737×3642 | 3737×3642 | 3880×3080 |

Features

Horizontal machining centers HDAL series have high speed, high rigidity and high torque, equipped with advanced spindle cooling system and double table auto-rotation to enhance machining efficiency and increase economic benefits.

- Machine base, column, spindle box, cross slide, table and other basic parts are all made of high-strength cast iron, which has stable organization and permanently ensures the quality. The machine tool casting structure has been analyzed by machine dynamics and finite element analysis, and reasonably matched with the reinforcement structure to ensure the high rigidity of the base parts. The wide and solid machine base, portal column, and fully load-supported cross slide can ensure the heavy load capacity during machining. The indexing table adopts high-precision mouse tooth positioning. Sliding guideway ensures high rigidity of the machine.

- Ball screws and servo motors are directly coupled with flexible couplings for high efficiency and low backlash. Three-axis ballscrews are pre-stretched to minimize temperature rise elongation. After the ball screw is pre-stretched, it greatly increases the transmission rigidity and eliminates the effect of thermal deformation generated during rapid movement, thus ensuring the positioning accuracy and repeatability of the machine tool.

- The tool magazine adopts bi-directional shortest path tool selection, and the machine adopts double-arm automatic tool changing arm and cam wheel tool changing machinery, which is fast and stable.

- High-precision spindle/tool magazine: High-precision design, supported by precision grade angled ball bearings, to ensure high strength and high stability of cutting of machined workpieces. The spindle is driven by high torque gears.

- CNC system: rich software functions, strong functions, CNC system can be equipped with workpiece/tool measurement interface, standard RS-232 interface. The machine realizes electromechanical integration, compact structure, small footprint, easy installation, debugging and operation.

- Electricity: The wiring in the electrical box is in accordance with CE safety standards to ensure that the control system operates without external interference. Adopt heat exchanger, make the hot air inside the electric box quickly discharged, keep the constant temperature inside the box, make the control system can operate stably for a long time.

High speed horizontal machining center HDAL series machine tool with perfect performance and stable accuracy, it is suitable for machining various types of box parts and two-dimensional and three-dimensional surfaces.

Widely used in automotive, mold, machinery manufacturing and other industries, box parts, shell parts, disk parts, shaped parts processing, parts can be automatically completed after a clamping four-face milling, boring, drilling, expanding, reaming, tapping and other multi-processing.

Standard accessories:

- Automatic tool changer system (MG24, ATC)

- Screw chip conveyor (both sides)

- Enclosed guard

- Automatic lubrication system

- Rigid tapping

- Adjustable pad iron

- Spindle cooling device

- Workpiece cooling device

- Tools and tool box RS-232 transmission system

- Electrical cabinet and heat exchange system

- Gear head spindle

- Machine Tool Working Lights

- Warning light

- USB interface

- Ground and leakage circuit breakers

Optional accessories:

- Elevated chip conveyor

- High pressure cooling unit

- Cleaning water gun

- Cleaning air gun

- Raster scale

- Electrical cabinet air conditioning

- Workpiece automatic inspection system

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com