PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

High Speed Horizontal Machining Center MDU Series

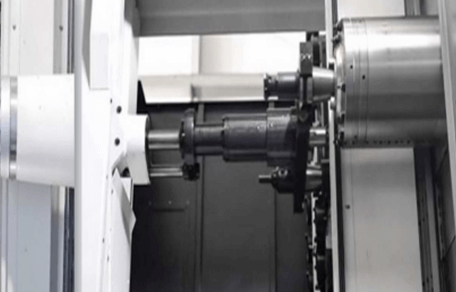

Horizontal machining center MDU series overall bed, adopting positive “T” structure, the machine tool is mainly made of resin sand casting, the screw adopts hollow cooling technology, the spindle is an electric spindle structure, to ensure the overall machine tool of high rigidity, high accuracy and high performance, to ensure high efficiency, high speed, and high cost-effective machining of parts.

- Table size: 1250×1250mm

- Table maximum load: 3000kg

- X/Y/Z axis travel: 1700/1400/1240mm

| Specifications | Unit | MDU40P | MDU50PS | MDU50 | MDU50A | MDU65S | MDU65 | MDU65A | MDU80S | MDU80 | MDU80A | MDU100S | MDU125 |

| Worktable size (L*W) | mm | 400×400 | 500×500 | 500×500 | 500×500 | 630×630 | 630×630 | 630×630 | 800×800 | 800×800 | 800×800 | 1000×1000 | 1250×1250 |

| No. of Pallet | 2 | 2 | 2 | 2 | 2 | ||||||||

| Table type | IT Opt:BRT | IT Opt:BRT | IT Opt:BRT | IT Opt:BRT | IT Opt:BRT | ||||||||

| Table indexing | IT (1°×360°) BRT (0.001°×360°) | IT (1°×360°) BRT (0.001°×360°) | IT (1°×360°) BRT (0.001°×360°) | IT (1°×360°) BRT (0.001°×360°) | IT (1°×360°) BRT(0.001°×360°) | ||||||||

| Table indexing time | s | 1.9(90°) | 1.7(90°) | 1.7(90°) | 4.5(90°) | 5(90°) | |||||||

| Pallet changing time | s | 5 | 6 | – | 6 | 12 | — | 12 | 12.5 | — | 12.5 | 35 | |

| mm | φ700×1000 | φ800×1050 | φ1110×1220 | φ1300×1320 | φ1900×1520 | ||||||||

| Max. table load | Kg | 400 | 800 | 1300 | 2000 | 3000 | |||||||

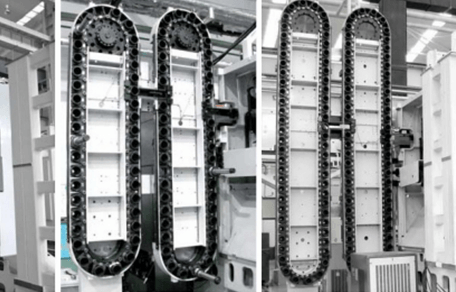

| Tool magazine capacity | T | 40 (Opt:60/80/120) | 40 (Opt:60/80/120) | 40 (Opt:60/80/120) | 40 (Opt:60/80/120) | 40 (Opt:60/80) | |||||||

| Tool shank type | BT40 | BT50 | BT50 | BT50 | BT50 | ||||||||

| Max. tool length | mm | 350 | 500 | 500 | 500 | 500 | |||||||

| Max. tool weight | Kg | 8 | 25 | 25 | 25 | 25 | |||||||

| Max. tool diameter (w/o adjacent tools) | mm | φ82(φ150) | φ115(φ270) | φ115(φ270) | φ115(φ270) | φ115(φ270) | |||||||

| Tool changing time(T-T) | s | 1.2 | 2 | 2 | 2.5 | 2.5 | |||||||

| X/Y/Z axis positioning accuracy | mm | 0.008 | 0.008 | 0.010 | 0.010 | X:0.015 Y:0.012Z:0.012 | |||||||

| X/Y/Z axis repeatability accuracy | mm | 0.005 | 0.005 | 0.006 | 0.006 | X:0.007 Y:0.007Z:0.007 | |||||||

| Spindle taper | No.40(7:24) | No.50(7:24) | No.50(7:24) | No.50(7:24) | No.50(7:24) | ||||||||

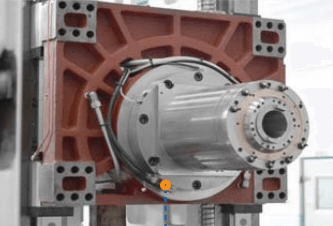

| Standard configuration Max spindle speed | rpm | 10000(Direct-Drive) | 8000(Electric spindles) | 8000(Electric spindles) | 8000(Electric spindles) | 6000(Electric spindles) | |||||||

| Optional configurations Max spindle speed | rpm | 12000(Direct-Drive) | 12000(Electric spindles) 6000(Gear spindle) | 12000(Electric spindles)6000(Gear spindle) | 12000(Electric spindles) 4000(①Gear spindle) 4000(②Gear spindle) | 8000(Electric spindles)12000(Electric spindles)6000(Gear spindle) | |||||||

| Standard configuration Spindle motor power (Continueous /30 min) | kW | 7.5/11/15(10000rpm) | 18.5/22(8000rpm) | 18.5/22(8000rpm) | 25/30(8000rpm) | 37/45(6000rpm) | |||||||

| Optional configurations Spindle motor power (Continueous/30 min) | kW | 7.5/11/15(12000rpm) | 25/30(12000rpm)22/26(6000rpm) | 25/30(12000rpm)22/26(6000rpm) | 25/30(12000rpm) 22/26(①4000rpm) 30/37(②4000rpm) | 25/30(8000rpm)25/30(12000rpm)22/26(6000rpm) | |||||||

| Standard configuration Max spindle output torque | Nm | 95.5(10000rpm) | 292(8000rpm) | 292(8000rpm) | 420(8000rpm) | 653(6000rpm) | |||||||

| Optional configurations Max spindle output torque | Nm | 95.5(12000rpm) | 420(12000rpm)1025(6000rpm) | 420(12000rpm)1025(6000rpm) | 420(12000rpm) 827.7(①4000rpm) 1529(②4000rpm) | 420(8000rpm)420(12000rpm)2049(6000rpm) | |||||||

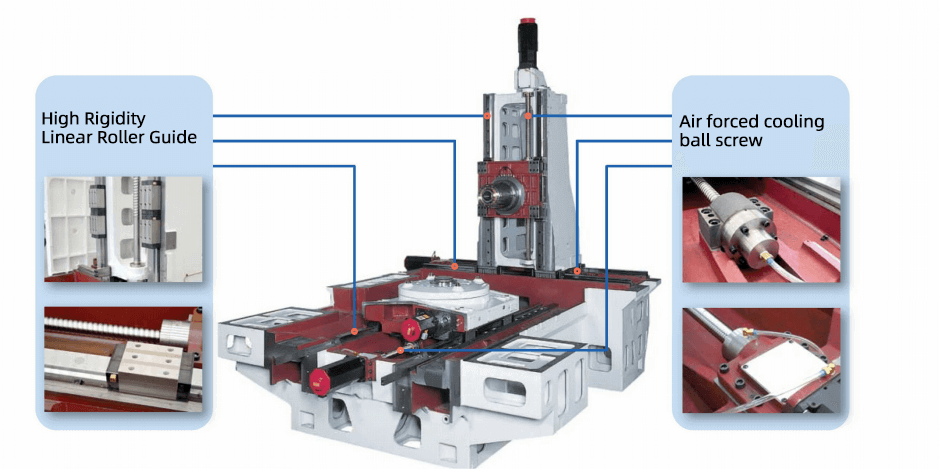

| Guideway form | Roller Linear Guideway | Roller Linear Guideway | Roller Linear Guideway | Roller Linear Guideway | Roller Linear Guideway | ||||||||

| Coordinate travel | mm | 630/620/710 | 780/750/800 | 1050/900/900 | 1050/900/800 | 1400/1100/1050 | 1400/1100/1000 | 1700/1400/1240 | |||||

| Rapid Movement Speed | m/min | 60 | 54 | 54 | 45 | 45 | |||||||

| Max cutting speed | m/min | 40 | 20 | 20 | 20 | 20 | |||||||

| CNC system | FANUC 31i-B | ||||||||||||

| Machine dimensions | mm | 5952*2558*2771 | 4912*3200*3125 | 5145*3342*3355 | 6153*3717*3827 | 8180*6087*3702 | |||||||

| Net weight | kg | 8000 | 8000 | 15000 | 14000 | 15000 | 18000 | 16500 | 18500 | 24000 | 21000 | 24500 | 32500 |

Features

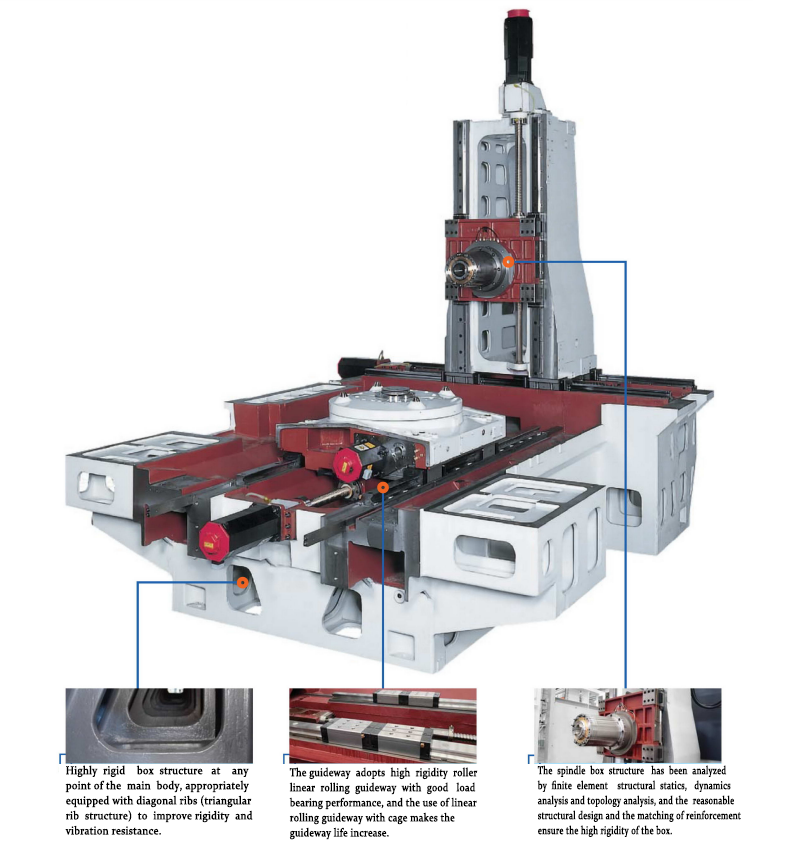

The machine tool as a whole is applied to the digital simulation model by optimizing the design and the characteristic parameters of the bonding surfaces of the moving parts to improve the rigidity of the machine components. In the process of structural optimization design of the machine tool, topology optimization design of the main components is carried out to improve the static and dynamic characteristics of the machine tool.

- The main parts are all resin sand castings, and the bed is a monolithic casting on which the column, slide table, and table move. The exchange table and tool magazine manipulator are fixed on the bed to ensure the overall rigidity of the machine.

- Positive “T” type integral casting bed structure, bed design after finite element analysis, its structure is reasonable, the rib plate arrangement is appropriate, so as to have sufficiently high static and dynamic stiffness and accuracy retention.

| Gearbox housings |

Engine block |

Engine cylinder head |

Reduction gear housing |

Communication equipment housing |

Gearbox end caps |

Electric vehicl water cooler housing |

Electric vehicle controller shell |

Machine internal rigidity diagram

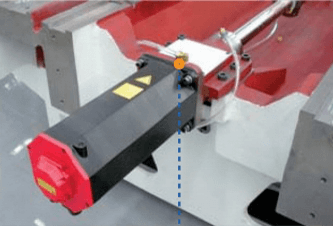

- This horizontal machining center series’ cooling device for the spindle and ball screws of each axis is realized by circulating the cooling liquid compulsorily through the pump in the thermostatic controller oil cooler.

- The X, Y and 2 coordinate screws all adopt hollow strong cooling technology, and the temperature of the cooling oil is controlled in real time so that it changes in a small temperature range, thus reducing the thermal deformation of the screws in the process of cutting force and rapid movement.

- High-performance hollow and strongly cooled ball screws will be semi-closed-loop CNC machine tool positioning accuracy greatly improved to ensure that the machining center can be a long time in high-precision operation; and, high-performance hollow and strongly cooled ball screws effectively reduce the inertia of high-speed movement, increasing the twisted stiffness of the screw.

Spindle temperature compensation technology

- Spindle temperature compensation function is an effective means to improve spindle precision machining accuracy, MDU series horizontal machining centers successfully apply this technology to make the machine tool accuracy has been effectively improved.

- The principle is to collect the temperature and deformation data of the spindle through the stereotyped machine tool, and then mathematically analyze these data and establish mathematical models, and then establish the compensation software through the mathematical models.

- In the process of using the machine tool, the temperature sensor outside the spindle dynamically feeds back the temperature to the temperature compensation software of the numerical control system and compensates through the X, Y and Z coordinates.

Reliable automatic pallet exchange and positioning

High-precision rotary table positioning and clamping mechanism adopts imported positioning taper pins, which improves the positioning accuracy and repetitive positioning accuracy of pallet exchange. When the pallet is exchanged, strong gas is injected from the cone head to remove the chips on the cone surface to ensure the accurate positioning of the pallet.

T-turn table 1°x360° (standard configuration)

The indexing is positioned by a rat-tooth disk, which ensures indexing positioning and withstands large loads, and locking and unlocking are controlled hydraulically. The use of air seals and gear-driven construction extends service life and increases reliability even under overload conditions. This table can realize a minimum indexing angle of 1°.

BRT rotary table 0.001°x360° (optional)

Indexing by servo motor driven gear reducer or worm gear, rotary encoder positioning, can realize four-axis linkage processing, locking and unlocking are controlled by hydraulic pressure to increase reliability. This table can realize the minimum indexing angle of 0.001°.

Automatic tool change system

Automatic tool change system

Automatic tool change system

Automatic tool change system

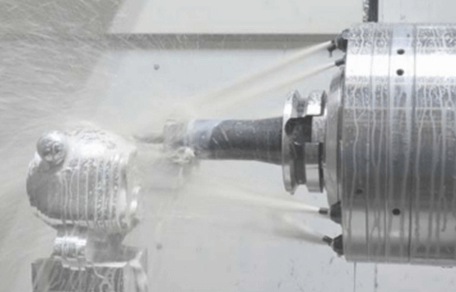

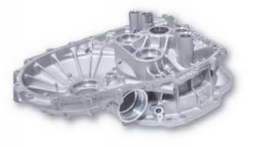

Applications

Horizontal machining center MDH series is suitable for the machining of precision box parts, shell parts, disk parts and shaped parts in the machinery manufacturing industry, which can automatically complete the multi-process machining of milling, boring, drilling, expanding, hinging and tapping of four surfaces after one clamping. It has the advantages of high degree of automation, strong reliability, simple, convenient and pleasant operation, beautiful and generous overall shape, and high degree of mechatronics.

Gearbox housings

Engine block

Engine cylinder head

Reduction gear housing

Communication equipment housing

Gearbox end caps

Electric vehicle water cooler housing

Electric vehicle controller shell

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com