PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

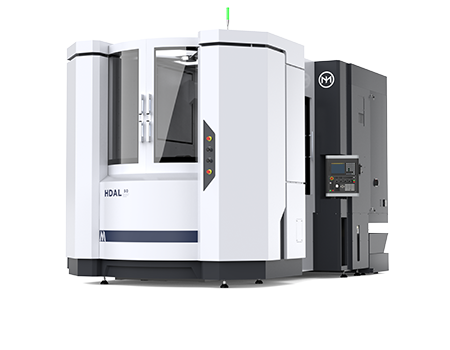

Horizontal Flexible Manufacturing Cell FMC Series

Horizontal flexible manufacturing cell FMC series, a highly efficient automated machine tool designed for automotive, mold and machinery manufacturing industries, is suitable for multi-species and small batch production. Features of the machine include high-precision hollow-cooled screws, high-speed electric spindles, high-rigidity resin sand casting structures, rapid traverse speeds and linked tool-changing mechanisms to ensure machining accuracy and efficiency. In addition, it is equipped with FANUC31i-B numerical control system, which realizes high automation and flexibility of the machine.

- Table size: 500×500mm

- Max.load: 400kg

- X/Y/Z axis travel: 780/750/800mm

Specification | Unit | FMC4008 | FMC5008 |

Table size | mm | 400×400 | 500×500 |

Max. table load | kg | 400 | 400 |

Table indexing(A×C) | ° | 1°×360° | 1°×360° |

Number of switching tables |

| 8 | 8 |

Travel X/Y/Z | mm | 630/620/710 | 780/750/800 |

Rapid Movement Speed | m/min | 60 | 54 |

Spindle speed | rpm | 10000 | 8000 |

Tool shank form |

| BT40 | BT50 |

Tool magazine capacity |

| 40 | 40 |

Tool change time | s | 1.2 (Tool-tool) | 2 (tool-tool) |

Max. tool weight | kg | 8 | 25 |

Max. tool diameter | mm | φ82 | φ115 |

Max. tool length | mm | 350 | 500 |

Workstation switching time | s | 5 | 6 |

Machine weight | kg | 10000 | 19000 |

Machine floor space | mm | 4000×7400 | 4090×7955 |

Features

- High precision – machine tool X, Y, Z three coordinates of the screw all use advanced hollow cooling technology, effective control of the machine tool machining movement in the process of heat deformation problems, improve the machining accuracy of the machine tool, in addition, the machine tool has a temperature compensation function in the body of the main position is equipped with temperature sensing elements through the CNC system to analyze and compensate for the coordinates of the bit to achieve the accuracy of the machine tool bones

- High speed – machine tool spindle adopts electric spindle structure, speed up to 12,000rpm and has internal two-speed, can meet the requirements of low-speed cutting at the same time to meet the requirements of high-speed machining; X, V, Z three coordinate guideway adopts a high rigidity of the linear rolling guideway, its rapid traverse speed up to 60m/min; machine tool adopts a linkage tool changer (tool change time: 2 seconds).

- 3, high rigidity – the main part of the machine tool are all resin sand castings, the bed is a whole casting, column, slide table, table movement on it. Exchange table and tool magazine manipulator are fixed on the bed bodyensure the overall rigidity of the machine tool. In addition, the machine tool in the design process through the finite element analysis to make the structure more reasonable.

- Multi-station–The machine tool adopts advanced CNC system to control the automatic exchange of 8 stations, which can realize loading 8 workpieces at one time and can automatically complete the milling, boring drilling, expanding, hinging, tapping, and space curved surfaces and other processes of 4 surfaces and the circumference of each workpiece, so as to realize flexible machining.

Applications

- Horizontal flexible manufacturing cell FMC series is widely used in automobile, mold, machinery manufacturing and other industries for the processing of box parts, shell parts, disk parts, shaped parts. This machine tool adopts advanced digital control system which can load 8 workpieces at one time and can automatically complete the milling, boring, drilling, expanding, hinging, tapping and space curve surface processing of 4 surfaces and circumference of each workpiece, which is suitable for the processing of small batch and multi-species parts.

- the use of internal two-speed variable speed high-speed spindle to ensure that the machine tool high and low speed machining performance and high-speed machining;

- High-precision hollow cooling screw technology improves the machining accuracy of the machine tool;

- Temperature compensation technology improves machining accuracy;

- the machine tool 60m/min rapid traverse speed shortens the machining time and improves the machining efficiency;

- The machine tool adopts linkage tool change mechanism (tool change time: 2 seconds);

- the bed is a whole casting, machine tool in the design process through finite element analysis to make the structure more reasonable;

- FANUC31i-B numerical control system.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com