PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

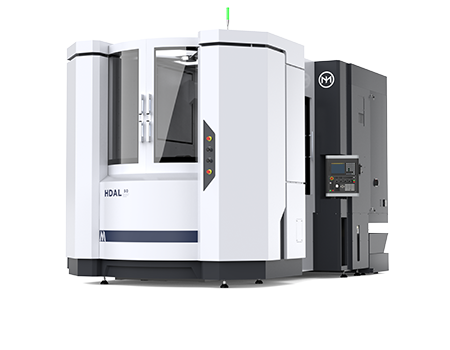

Horizontal Machining Center MDL Series

Horizontal machining center MDL series realizes high-precision and high-efficiency multi-process automated machining with its linear tool magazine, on-line manual tool change, flexible logistics loading and unloading methods, oil-air lubrication, spindle temperature compensation, high-speed cooling, dynamic balance experiment and thermal deformation compensation technology, as well as fast moving speed, which is especially suitable for mass production of precision parts such as plates, disks and boxes.

- X/Y/Z axis travel: 1000/800/630mm

- Spindle speed: 50~6000rpm

- X/Y/Z axis feed speed: 1~10000mm/min

Specifications | Unit | MDL50 | MDL63 | MDL63A |

X/Y/Z axis travel | mm | 800/800/630(Inline spindles)800/800/610(electric spindle) | 800/800/630(Inline spindles)800/800/600(electric spindle) | 1000/800/630 |

X/Y/Z axis Max. rapid traverse | m/min | 54 | 40 | 40 |

X/Y/Z axis feed speed | mm/min | 1~10000 | 1~10000 | 1~10000 |

Spindle speed | rpm | 50~10000(Inline spindlesⅠ)50~5000 (Inline spindlesⅠ型)50~18000(electric spindle) | 50~6000(Inline spindles)50~12000(electric spindle) | 50~6000(Inline spindles) |

Spindle taper | mm | HSK63A | HSK100A | HSK100A |

Spindle diameter | φ80 | φ100 | φ100 | |

Transmission type | Stepless | |||

Spindle motor power | kw | 15/18.5(Inline spindles)25/35 (electric spindle) | 22/26(Inline spindles25/55(electric spindle) | 22/26 |

Spindle lubrication | Oil and grease lubrication(Inline spindles)Oil-air lubrication(electric spindle) | Oil and grease lubrication(Inline spindles)Oil-air lubrication(electric spindle) | Oil and grease lubrication | |

Tool capacity | 24 | 28 | 28 | |

Tool selection | Randomization | Randomization | Randomization | |

Tool change time | s | 7(cut – cut) | 7(cut – cut) | 7(cut – cut) |

Max. tool diameter | mm | φ75 (empty space: φ150) | φ110 (empty space: φ230) | φ110(empty space:φ230) |

Max. tool length | mm | 360 | 390 | 390 |

Max. tool weight | kg | 8 | 20 | 20 |

Positioning Accuracy | mm | 0.008 | 0.008 | 0.008 |

Repeat positioning accuracy | mm | 0.004 | 0.004 | 0.004 |

Machine dimensions(L*W) | mm*mm | 2000×4800 | 2100×5050 | 2300×5050 |

Net. weight | kg | 9000 | 11000 | 12000 |

CNC system | FANUC 31i | FANUC 31i | FANUC 31i |

Features

- Horizontal machining center MDL series adopts three-coordinate form in structure, and the tool magazine is a linear tool magazine, which is placed on the top of the machine, narrowing the width of the machine, making the structure of the machine more disciplined and compact, and realizing the tandem and parallel grouping of the machine very well. It improves the utilization rate of the plant floor and saves cost for users.

- Configuration for the machine tool online manual tool changer can not affect the work of the machine tool to complete the task of tool exchange, improve the degree of automation of the machine tool.

- In terms of logistics, relying on the simple and compact layout of the machine tool, a variety of workpiece loading and unloading methods can be selected such as truss manipulator, machine by-pass type, machine front through type, etc., which is convenient for the layout of the production line.

Key technical indicators

- Spindle bearing adopts oil and gas lubrication technology, which prolongs the working life of the bearing and improves the reliability of high-speed operation of the spindle;

- Advanced spindle temperature compensation technology is applied to realize dynamic compensation of thermal error of machine tool and improve machining precision;

- Applying high-speed spindle circulating water cooling technology effectively reduces the heat generation of spindle stator and front-end bearing, ensures the spindle rotary runout precision, and meets the machining precision of workpiece;

- High-speed electric spindle dynamic balance experiments, so that the spindle in the high speed operation is reliable, the machine tool to achieve high-speed cutting.

- Use machine tool drive thermal deformation compensation technology to offset the error generated by thermal deformation of the screw during high-speed operation;

- The fast moving speed of machine tool 54m/min shortens the machining time and improves the machining efficiency;

- The bed is a whole casting, machine tool in the design process through the finite element analysis to make the structure more reasonable.

Applications

- Line three coordinate horizontal machining center HDL series the machine tool can be widely used for plate, plate, box, shell and precision parts processing, parts can be machined after a clamping to complete the milling, boring, drilling, expanding, hinging, tapping and other processes, not only for the process of concentrated parts of the many varieties of small and medium batch machining, but also for the composition of flexible machining automatic line, complete the automotive industry, the engine cylinder, the cylinder head of the large-scale production of the cylinder head.

- Widely used in automobile manufacturing, machinery manufacturing, aerospace and new energy industries.

| Configuration | HDL50 | HDL63 | HDL63A |

| Automatic Tool Changer System | ● | ● | ● |

| Enclosures | ● | ● | ● |

| Automatic lubrication system | ● | ● | ● |

| Rigid tapping | ● | ● | ● |

| Spindle cooling unit | ● | ● | ● |

| RS-232 transmission system | ● | ● | ● |

| Electrical cabinet and heat exchange system | ● | ● | ● |

| Inline spindles(10000rpm) | ● | × | × |

| Inline spindle (5000rpm) | O | × | × |

| Inline spindle (6000rpm) | × | ● | ● |

| Electric spindle (18000rpm) | O | × | × |

| Electric spindle(12000rpm) | × | O | × |

| Hydraulic systems | o | O | × |

| Earth leakage breaker | ● | ● | ● |

| Tool magazines: 24 | ● | × | × |

| Tool magazines: 28 | × | ● | ● |

| Spindle internal cooling | ● | ● | ● |

| Optical encoder | O | O | ○ |

| Manual tool changing systems | ● | ● | ● |

| Tool breakage detection device | ● | ● | ● |

| Spindle oil-air lubrication system | O | O | × |

Note: ● is standard ○ is optional × is not optional

If you have problems with the attachments inside the configuration, you can contact our engineers to do a customized configuration.

Related Products

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com