PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

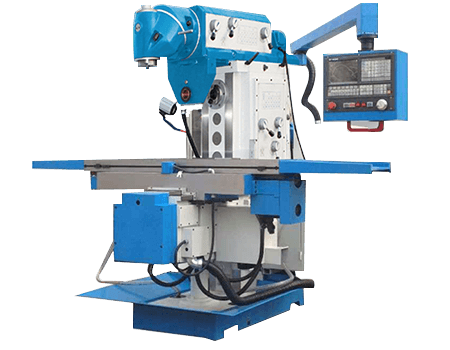

Conventional Horizontal Lift Table Milling Machine Series

Horizontal milling machine its spindle and table parallel, horizontal position, speed 12 levels, available in a variety of cylindrical milling cutter, circular slice milling cutter, angle milling cutter, molding milling cutter and end milling cutter processing a variety of flat, oblique, groove, etc.. It is characterized by wide machining range and large cutting force, and is suitable for machining large workpieces.

- Table size: 1600×360mm

- Table travel(X/Y/Z): 1300/320/450mm

- Table rapid speed (X/Y/Z): 1300/320/450mm

Specification | Unit | XL6036C | XL6036CL | XQ6032A | XQ6032C |

Table size | mm | 1325×360 | 1600×360 | 1370×320 | |

Table travel(X/Y/Z) | mm | 1100/320/450 | 1300/320/450 | 820/300/400 | 1000/380/400 |

Table feed(X/Y/Z) | mm/min | 8 steps30-750/20-500/15-375 | XY:30-830 Z:23-625 | ||

Table rapid speed (X/Y/Z) | mm/min | 1200/800/600 | 1335/1335/1000 | ||

T-slots(NO:/width/pitch) | mm | 3/18/80 | 3/14/80 | ||

Spindle taper | 一 | 7:24 ISO50 | 7:24 ISO40 | ||

Horiontal spindle speed range | r/min | 12 steps 60-1800 | 12 steps 35-1500 | ||

Distance between spindle nose and table | mm | 20-470 | 75-475 | ||

Distance from spindle axis to arm | mm | 175 | 155 | ||

Main motor power | kw | 5.5 | 3 | ||

Torque of X/Y/Z axis AC servo motor | N. m | 15 | 15 | ||

Overall size | mm | 2245×2100×1870 | 2520×2100×1870 | 1820×1680×1730 | |

Net weight | kg | 2500 | 2550 | 1600 | 1700 |

Features

- The spindle taper can be fitted with a variety of cylindrical/blade/milling cutters, form milling cutters, face milling cutters and other tools either directly or through accessories.

- Table and guide rail are audio quenched for high strength.

- The automatic tool walker X/Y/Z direction can realize manual feeding and electric feeding, and the feeding speed can meet different machining requirements.

- The spindle adopts energy-consumption braking, with large braking torque, fast and reliable stopping.

Applications

- Conventional horizontal milling machines excel at machining parts such as flat surfaces, grooves, gears and complex curved surfaces with their stable table and precise tool control. They are usually equipped with milling heads in horizontal or vertical layouts, enabling multi-directional milling operations and are suitable for heavy cutting and precision milling.

- Suitable for mass production and restorative work, they are widely used in a variety of fields such as machine building, automotive industry, aerospace and mold making.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com