PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

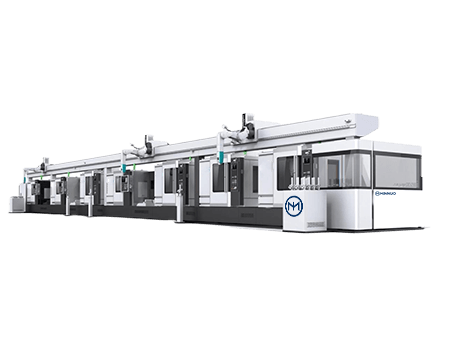

Motor stator housing machining automatic line

The Motor Stator Housing Machining Automatic Line is a precision manufacturing solution launched by Minnuo to improve the productivity of machining motor stator housings.

Production line composition

- The automatic line consists of 11 main machines, including DL-20MHS dual spindle CNC lathe, CL-20A/I CNC lathe and VDR600 vertical machining center.

- Auxiliary equipment includes 8 loading machines, cleaning machines, inspection machines, press-fit machines, leak-testing machines, measuring machines and unloading devices.

- The line is equipped with two independent truss manipulators for automated loading, unloading and conveying of components.

Production Line Highlights

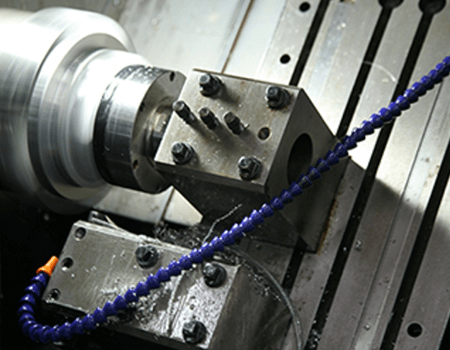

- Integration of dual-spindle CNC lathes allows for simultaneous machining from both sides, increasing productivity.

- Vertical machining centers are critical for complex operations requiring vertical tool movement.

- The use of a truss robot minimizes manual intervention, reduces the potential for human error and improves safety.

Range of Applications

This automated line is particularly well suited to industries that require high volume production of motor stator housings, such as automotive, industrial machinery and appliance manufacturing.

Advantages

- Efficiency: the automated nature significantly reduces the time from raw material to finished product.

- Accuracy: The use of CNC technology ensures high precision in the manufacturing process.

- Consistency: Automated processes reduce variability, leading to more consistent product quality.

- Cost-effectiveness: Although the initial investment can be considerable, reduced labor costs and increased efficiency can reduce total production costs over time.

- Designed for efficiency, the entire line has a total length of 62.3 meters and a cycle time of 1.91 minutes per piece, indicating the entire processing time from raw material to finished product.

Customization and scalability

- The line can be customized to meet specific production requirements, such as type of stator housing, material specifications and throughput needs.

- The modular design allows for scalability, meaning additional machines or robots can be integrated to meet growth in production demand.

The automated motor stator housing machining line represents a major advance in manufacturing technology, providing a comprehensive solution for the efficient and accurate mass production of motor stator assemblies. It is ideal for manufacturers seeking to automate and optimize their production processes.

Minnuo Machinery, as an advanced machine tool manufacturer in China, has designed and developed the motor stator housing machining automation Line. Interested parties can contact our company via the contact information provided for more detailed information or to discuss specific requirements. Minnuo provides after-sales service including maintenance, spare parts and technical support to ensure that the line operates at optimum performance.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com