PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

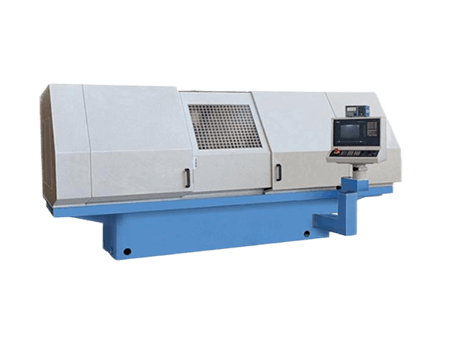

Automatic CNC Internal Grinding Machine MK2150 Series

MK2150 is a high-precision multifunctional internal grinding machine designed for automatic grinding of internal bores and internal and external end faces. It adopts Siemens servo system control to realize precise movement of table Z-axis and grinding wheel X-axis. The machine is equipped with a hydraulic membrane chuck and various clamping methods to ensure stable workpiece clamping. With bore roundness up to 0.003mm and surface roughness as low as Ra0.4μm, it is a high-quality choice for single-piece small-lot to high-volume production.

- Grinding hole diameter: 50-500mm

- Max. grinding depth: 450mm

- Max. swinging over the table: 725mm

Specifications | Unit | MK2150 |

Grinding hole diameter | mm | 50-500 |

Max. grinding depth | mm | 450 |

Max. swinging over the table | mm | 725 |

Max. table travel (Z-axis) | mm | 700 |

Max. travel of the wheel head (X-axis) | mm | 180 |

Max. speed of Z-axis | m/min | 8 |

Max. speed of X-axis | m/min | 5 |

Workpiece spindle speed | r/min | 30~300 |

Bore roundness | mm | 0.003 |

Cylindricity of bore | mm | 0.005 |

Surface roughness of bore | μm | Ra0.4 |

Surface roughness of end face | μm | Ra0.8 |

Perpendicularity of end face to bore | μm | 0.005 |

Max. turning angle of headstock | ° | 15 |

Total power of machine | kw | 19 |

Machine weight | kg | 6000 |

Features

The CNC Internal Grinding Machine MK2150 series is characterized by its highly efficient automated grinding capability and sophisticated control system. It is capable of automatically completing the grinding of bore and endface after the workpiece is clamped in one setup, ensuring the continuity and consistency of the machining process. The key moving parts of the machine, including the Z-axis of the table and the X-axis of the grinding wheel, are controlled by the Siemens AC servo system through high-precision ball screws, which ensures the precise movement of each axis.

- The grinding wheel holder and table of the machine are respectively equipped with linear rolling guideway and flat V-type molded guideway, which provide stable support and smooth movement. The high-precision roller bearings used in the headstock and the AC frequency conversion speed control system provide the machine with smooth speed changes.

- The workpiece clamping system includes a hydraulic membrane chuck, a tilting wedge type sliding jaw chuck and an end face chuck. These diverse clamping methods accommodate workpieces of different shapes and sizes, enhancing the versatility and flexibility of the machine.

- For dimensional control, the machine adopts fixed-range grinding and measurement in gauge machining to improve machining accuracy. The magnetic plus paper precision filter of the cooling system ensures the cleanliness of the coolant and prolongs the service life of the machine.

- The grinding wheel spindle is driven by a mechanical grinding head through a high-precision belt drive, providing stable grinding performance. The machine’s fully enclosed hood and mist absorbing device not only enhance the safety of operation, but also meet the safety and protection standards of modern machine tools.

- In addition, the machine’s guideways and ball screws are lubricated by a centralized automatic lubrication station, which reduces maintenance workload and improves the machine’s operating efficiency. The integrated design of the electrical box and the machine simplifies the installation process and saves space.

Applications

- Fully automatic CNC internal grinding machine MK2150 series is mainly used for grinding internal bore, internal concave endface, external endface, multi-stage internal bore, multi-stage endface, and is a multi-purpose production machine tool. The entire grinding cycle of the machine is completed automatically, including automatic feeding, automatic dressing of the grinding wheel, automatic compensation, automatic size control, and the operator only needs to assemble and disassemble the workpiece. The machine is suitable for both single-piece, small-lot and large-lot production.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com