PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

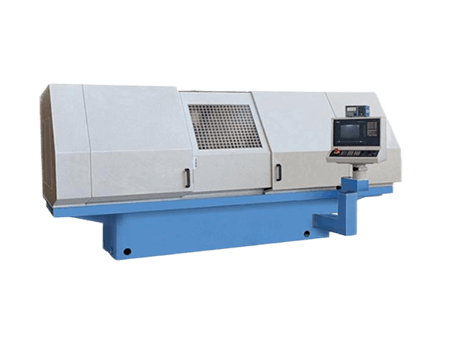

CNC Deep Hole Internal Grinding Machine MX2001 Series

Deep hole internal grinding machine MX-2001 is a 3-axis Siemens CNC composite grinding machine, which can grind deep holes, end faces and internal arc surfaces in a single clamping; as well as on-line inspection of machining accuracy of hole diameter and step depth after grinding. It can complete the grinding of internal concave end face, internal arc surface, multi-stage bore, multi-stage end face and so on.

- Grinding hole diameter: φ40-φ100mm

- Effective grinding depth: 900mm

- Max. swinging of the workpiece: φ400mm

Specifications | Unit | MX-2001 |

Grinding hole diameter | mm | φ40-φ100 |

Effective grinding depth | mm | 900 |

Max. swinging of the workpiece | mm | φ400 |

Max. table travel(axis Z) | mm | 1200 |

Max. table travel(axis X) | mm | 500 |

Work speed | r/min | 5-500 |

Wheel spindle speed | r/min | 5000-12000 |

Total power | KW | 25 |

Roundness of the bore | mm | 0.005 |

Cylindricity of the bore | mm | 0.01 |

Surface roughness of the bore | μm | Ra0.4 |

Surface roughness of the endface | μm | Ra0.5 |

Coaxiality of bore to OD | mm | 0.01 |

Machine weight | Kg | 10000 |

Features

- Deep hole internal grinding MX2001 series table longitudinal movement (Z-axis), grinding wheel transverse feeding movement (X-axis) and workpiece servo rotary movement (B-axis) are driven by Siemens servo motors.

- The table longitudinal motion (Z-axis) and grinding wheel transverse feeding motion (X-axis) guideway adopts INA high-precision roller linear guideway, and the transmission adopts THK high-precision ball screw; the position control adopts HEIDENHAIN grating closed-loop control.

- The workpiece box adopts high-precision sleeve rolling spindle, Siemens spindle motor driven by synchronous belt rotation. It can realize stepless speed change, quick start/stop and any position positioning, three-axis interpolation linkage and other functions.

- Workpiece clamping adopts three-jaw chuck + center frame, or other special clamping methods.

- The machine is equipped with imported fluid sensor for quick tool setting and anti-collision system.

- The machine tool is equipped with an endoscopic camera, which is convenient to observe the internal situation of the processed products.

- The grinding wheel spindle adopts the imported electric spindle directly connected to the front end of the grinding rod, and the grinding rod can be replaced according to the processed parts. Its rotational speed adopts static frequency converter stepless speed regulation.

- The machine is equipped with automatic measuring device after grinding, which can measure the size and shape error and feedback to the machine control system.

- It adopts fully enclosed cover with mist absorbing device and reliable safety protection measures.

Applications

- Deep Hole Internal Grinding Machine is a multi-purpose production machine mainly used for grinding deep holes, concave internal end faces, internal curved surfaces, multi-stage bores and multi-stage end faces. The whole cycle of the machine can be carried out automatically, including automatic feeding, automatic dressing and automatic measuring. The machine is suitable for both single-piece small-lot and large-lot production.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com