PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

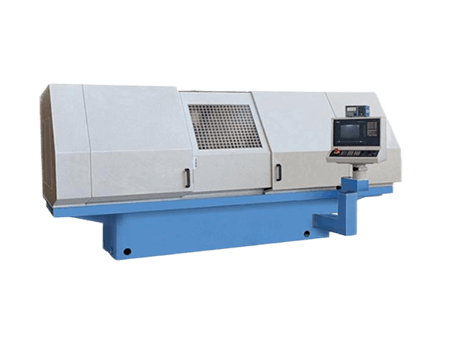

CNC Turret Internal Grinding Machine MK2120 Series

CNC turret internal cylindrical grinding machines MK2120 series are capable of automatic completion of the entire grinding cycle, including automatic feed, automatic dressing of the grinding wheel, automatic compensation, automatic control of dimensions, and the operator only needs to assemble and disassemble the workpiece. The machine is suitable for both single-piece, small-lot and large-lot production.

- Grinding hole diameter: 20-220mm

- Max. grinding depth: 200mm

- Max. swinging over the table: 620mm

Specifications | Unit | MK2120 |

Grinding hole diameter | mm | 20-220 |

Max. grinding depth | mm | 200 |

Max. swinging over the table | mm | 620 |

Max. table travel (Z-axis) | mm | 600 |

Max. travel of the wheel head (X-axis) | mm | 200 |

Max. speed of Z-axis | m/min | 8 |

Max. speed of X-axis | m/min | 5 |

Workpiece spindle speed | r/min | 100~500 |

Bore roundness | mm | 0.002 |

Cylindricity of bore | mm | 0.004 |

Surface roughness of bore | μm | Ra0.32 |

Surface roughness of end face | μm | Ra0.63 |

Perpendicularity of end face to bore | μm | 0.005 |

Max. turning angle of headstock | ° | 30 |

Total power of machine | kw | 18 |

Machine weight | kg | 4500 |

Features

- The workpiece is clamped once and automatically grinds the inner hole and inner and outer end faces.

- The table longitudinal movement Z-axis and grinding wheel transverse feeding X-axis drive are controlled by Siemens AC servo system with high-precision ball screws.

- The grinding wheel holder adopts linear rolling guide.

- The working table adopts flat V-shaped plasticized guide rail.

- The headbox adopts high-precision roller bearings and AC frequency conversion speed control.

- Workpiece clamping adopts hydraulic film chuck, inclined wedge type sliding jaw chuck and end face clamping chuck.

- Dimension control adopts fixed-range grinding and measuring instrument measurement in processing, fixed-range grinding accuracy of 0.015mm, measuring instrument grinding accuracy of less than 0.01mm.

- The coolant filtration adopts magnetic plus paper precision filtration device.

- The grinding wheel axis adopts high-precision belt-driven mechanical grinding head or electric grinding head.

- The machine tool adopts a fully enclosed cover with a mist-absorbing device and reliable safety protection measures.

- All rails and ball screws of the machine tool are centralized and automatically lubricated by the lubrication station.

- The electric box and the machine tool are of integral structure, so users do not need to connect the machine tool and the electric box, which occupies a small area.

Applications

- CNC turret internal grinding machine is mainly used for grinding internal bore, internal concave endface, external endface, multi-stage bore, multi-stage endface, it is a multi-purpose production machine tool.

- The machine tool is suitable for military single piece small lot production and can also be used for mass production in automobile and other industries.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com