PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

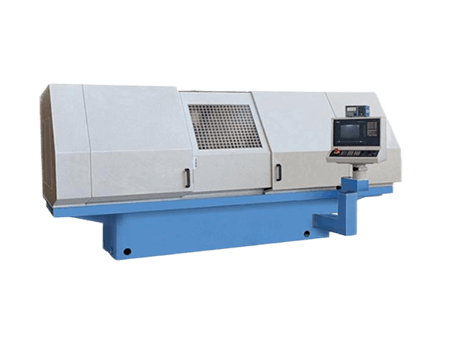

External Center Hole Face Compound Grinding Machine MX-2018

The internal grinding machine MX-2018 series is designed for the automotive fuel injection industry and is used for the center hole, internal end face, external circle and end face grinding processing of the valve parts of high pressure common rail hydraulic parts. The machine adopts a steel-inlaid artificial marble bed with good vibration absorption and dynamic stability. The Siemens 840 DSI servo control system and linear motor drive technology with high-precision scales ensure fast movement and precise control. Three grinding heads are arranged on the grinding frame of the machine, which are clamped once and chipped in separate processes. Imported high-precision pneumatic fixtures and automatic intelligent robot loading and unloading methods are adopted to meet the demand of intelligent mass production.

- Grinding diameter: 3-20mm

- Max. grinding depth: 20mm

- Max. clamping diameter: 30mm

Specifications | Unit | MX-2018 |

Grinding diameter | mm | 3-20 |

Max. grinding depth | mm | 20 |

Max. clamping diameter of workpiece | mm | 30 |

Max. movement of worktable (axis Z) | mm | 250 |

Max. movement of wheelhead(axis X) | mm | 680 |

Moving speed of worktable(axis Z) | m/min | 0-20 |

Moving speed of worktable(axis Y) | m/min | 0-20 |

Resolution of axis Z | mm | 0.0001 |

Resolution of axis X | mm | 0.0001 |

Rotating speed of work spindle | r/min | 0-4000 |

Swivel angle of the workhead | ° | ±1 |

Positional accuracy | mm | ±0.0025 |

Relocation accuracy | mm | ±0.0015 |

Max. speed of bore spindle | r/min | 105000 |

Max . power of bore spindle | KW | 2 |

Max. speed of OD spindle | r/min | 3000 |

Max . power of OD spindle | KW | 10 |

Grinding accuracy | ||

Roundness of bore | mm | 0.0005 |

Cylindricity of bore | mm | 0.001 |

Size deviation of bore | mm | ±0.002 |

Roundness of OD | mm | 0.001 |

Vertical deviation between OD and end face | mm | 0.0015 |

Size deviation of OD | mm | 0.008 |

Coaxiality of ID and OD | mm | 0.0015 |

Parallel deviation between internal end face and datum end face | mm | 0.01 |

Thickness deviation of internal end face | mm | ±0.01 |

Roughness | μm | Ra0.1 |

Machine size | mm | 2250×1700×2000 |

Total weight of machine | Kg | 5500 |

Features

- The machine is equipped with a steel and artificial marble bed with good vibration absorption and high dynamic stability.

- The machine has a fixed grinding frame, longitudinal reciprocating oscillation of the workpiece and transverse feeding grinding mode.

- Adopting Siemens 840DsI servo control system, the X-axis of feeding and Z-axis of reciprocating are directly driven by linear motors, equipped with high-precision absolute scales, with fast moving speed and high precision.

- The X-axis and Z-axis movement guideway of the machine tool adopts high-precision hydrostatic guideway imported from INA Company of Germany, which has high accuracy retention, high speed and good vibration resistance.

- Three grinding heads are arranged on the grinding frame of the machine, which are clamped at one time and chipped in separate processes. Among them, two German GMN imported high-speed spindles with center cooling are used for the processing of inner hole and inner end face respectively; the external grinding head is used for the processing of external circle and external end face.

- Diamond disc dressing grinding wheel, small grinding wheel adopts CBN grinding wheel, the whole cemented carbide joint rod, large grinding wheel adopts ceramic grinding wheel.

- Imported high-precision pneumatic fixture, fixture rotary accuracy and high repeat positioning accuracy.

- Automatic intelligent robot loading and unloading mode, to meet the needs of intelligent mass production.

Applications

- External round center hole and end face compound grinding machine MX-2018 series is mainly used for the grinding of internal hole and internal end face, external round and external end face of the valve parts of the hydraulic parts of the common rail for automobile fuel high pressure. It can also be used for the machining of center hole and seat surface and end surface of common rail injector valve body.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com