PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

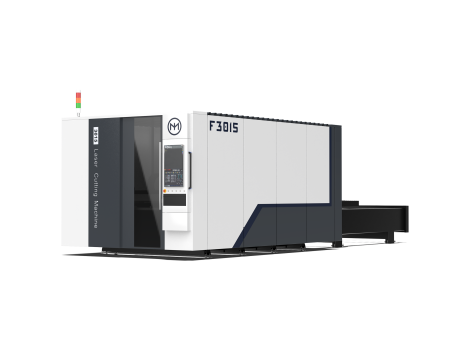

Precision Metal Sheet Laser Cutting Machine

Precision sheet fiber laser cutting machine small power models used with sheet metal industry, sheet metal cutting using gantry structure, integral welding beam, with high rigidity, stability, shock resistance. The use of high level control system, Yasukawa servo motors, powerful, to meet the processing of a variety of sheet metal, its AC co-servicing motor inertia is small, good dynamic performance.

- Laser power:1000w/1500w/2000w/3000w

- Cutting range: 1500*3000mm

- X/Y Positioning Accuracy: ±0.02mm

- Max Acceleration: 120m/Min

Machine table | 3015/4015/4020/6015/6020 | Repeat Positioning Accuracy | ±0.02mm |

Cutting range | 1500*3000mm | Working Voltage | 380v/50hz |

Laser power | 1000w/1500w/2000w/3000w | Maximum operating speed | 120m/min |

Acceleration | 1.5G | X/Y axis positioning accuracy | ±0.02mm/min |

Power consumption of the whole machine | ≤10kw | Idle speed | 100mm/min |

Machine operating humidity | <90% | Operating temperature | 0-40℃ |

Remarks: The worktable can be customized according to the customer’s requirements, such as the bed. | |||

Features

Precision metal sheet laser cutting machine adopts high-quality imported accessories and a high-level control system, with high rigidity, high accuracy, and superior dynamic performance, to meet the needs of efficient and accurate cutting of various metal sheets, widely used in sheet metal processing and other industries.

- In terms of accessories: servo motors, reducers, guide rails, etc. are selected from imported originals.

- In terms of precision: the selection of high-precision grinding teeth, imported guide rails, imported cutting head, etc., after a rigorous assembly process, to ensure the speed and precision of the machine cutting: the selection of the original imported cutting head, with a combination of high-speed and high-precision accessories, the perfect guarantee of the quality of cutting.

- Laser can be imported or domestically according to the customer’s own needs, and are free maintenance products.

Applications

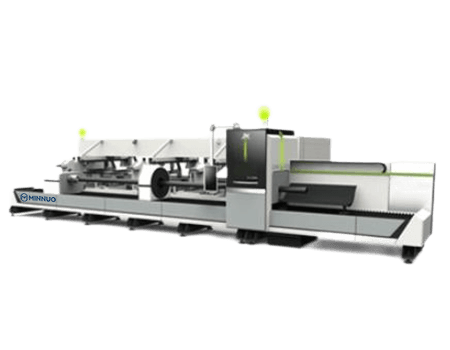

- Metal sheet laser cutting machine is widely used in kitchen appliances, sheet metal chassis cabinets, mechanical accessories, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment, various metal products, and sheet metal cutting and processing industries.

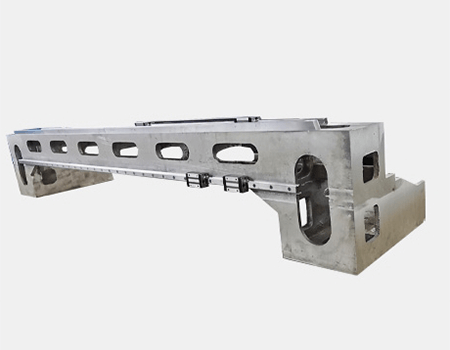

- Heavy plate welding bed: large mechanical mass, good stability, will not vibrate, high cutting precision, good integrity, high-temperature quenching bed does not deform, long service life.

- Laser generator: cost-effective, service life up to 100,000 hours, good cutting effect, strong stability (optional higher).

- Fiber optic cutting head: RAYTOOLS Jiaqiang or Wanshunxing WSX or imported PRECITEC international brands, long service life, stable, cost-effective.

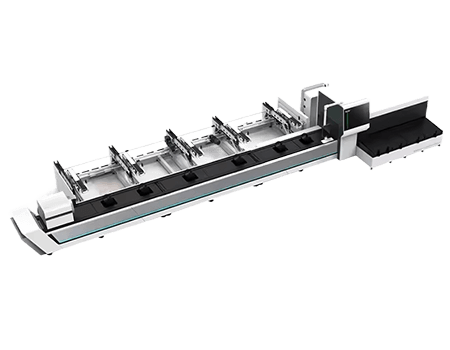

- Cast aluminum beam: lightweight, good steel, high precision, good dynamic characteristics to save power costs fast operation, and improve machining efficiency

- Guide rail: Taiwan on the silver or PMI or imported, the force is uniform, improves processing accuracy and stability, and life expectancy of up to 10 years

- Professional CNC cutting system: Bertru or Weihong can be chosen to operate to support a variety of CAD drawings to identify stable models.

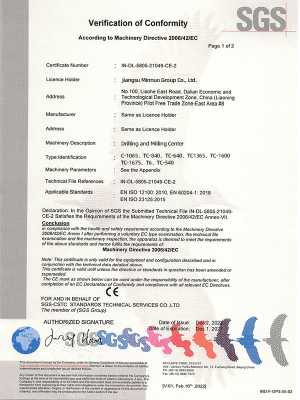

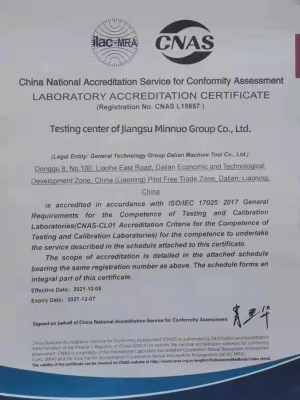

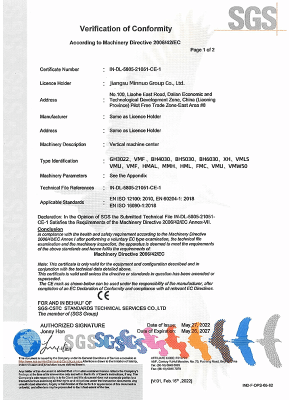

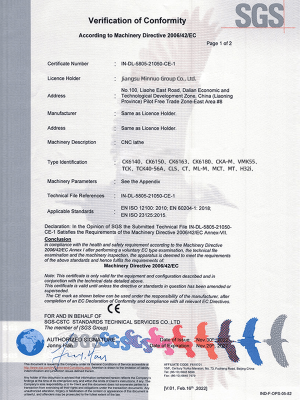

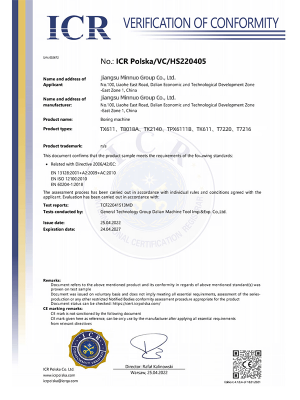

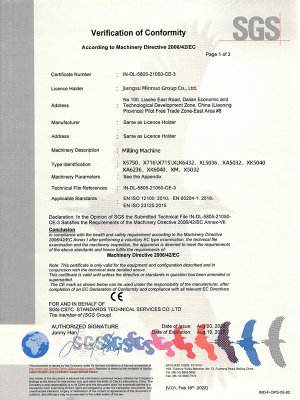

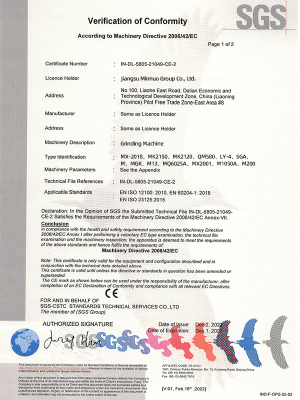

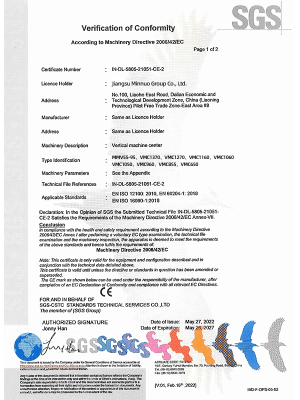

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com