PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

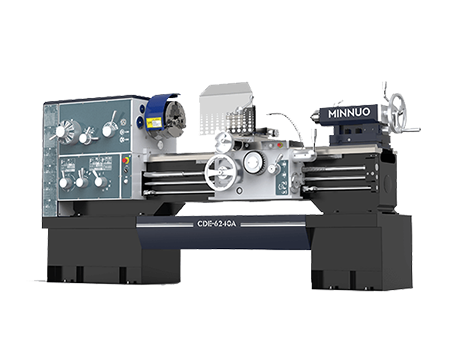

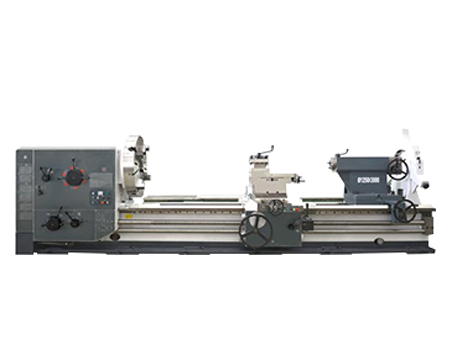

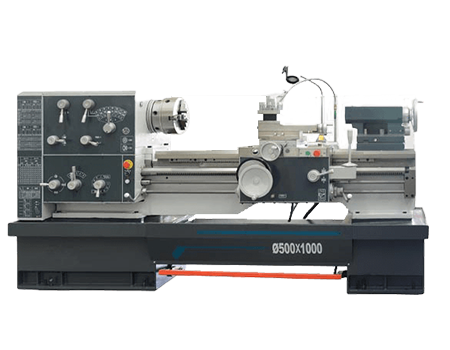

Conventional Lathe CDS series

The CDS-B/C series of conventional lathe incorporates the advanced technology of world-renowned lathe manufacturers to design a user-friendly machine. Its exterior design follows the modern minimalist style with spacious front and rear support legs. The machine’s guideways are high-frequency hardened and precision ground to a hardened hardness of G50. The gears in the headstock box are high-frequency hardened and finely ground to ensure that the gears are of grade 6 to 7 accuracy. This lathe is capable of machining a wide range of workpieces including steel, cast iron, non-ferrous metals and non-metallic materials, and the dimensional accuracy of the machined parts is up to grade IT7 and the surface roughness is up to grade 1.6, which meets the demand for high-precision machining.

- Max.Swing diameter over bed: Φ500/Φ660

- Max.Swing diameter over cross slide: Φ290/Φ440

- Maximum workpiece length: 1000/1500/2000/3000

Features

- Large Spindle Bore: B-type with 82mm, C-type with 105mm.

- High Spindle Speed: The spindle system is dynamically balanced, allowing for high rotational speeds and comprehensive adaptability to tooling techniques.

- High Rigidity: The main body of the machine tool is made entirely of resin-bonded high-phosphorus castings, and the structure of the main body of the machine tool is made more rational through finite element analysis and optimization.

- Aging Treatment for Bed Body, High-Frequency Quenching for Guide Rails: Enhances the machine tool’s longevity.

- Precision Grinding for Bed Guide Rails: Ensures high precision along the entire length of the guide rails.

- Vertical Lead Screw Equipped with Metal Protective Cover: Enhances the personal safety of operators.

- Rapid Traverse Mechanism in Both Vertical and Horizontal Directions on the Carriage: Makes the operation of the machine tool more convenient and efficient for operators.

Key technical indicators

- The bed head box adopts forced lubrication system.

- Bed headbox gears are processed with high-quality equipment.

- Produced and assembled with high-quality manufacturing mode.

Specification | Unit | CDS6150B/C | CDS6250B/C | CDS6166B/C | CDS6266B/C | |

Max.Swing diameter over bed | mm | Φ500 | Φ660 | |||

Max.Swing diameter over cross slide | mm | Φ290 | Φ440 | |||

Max.Swing diameter in gap | mm | – | Φ760 | – | Φ870 | |

Length in gap | mm | – | 280 | – | 280 | |

Max. workpiece length | mm | 1000/1500/2000/3000 | ||||

Max.cutting length | mm | 950/1450/1950/2950 | ||||

Bed guideway width | mm | 394 | ||||

Spindle nose |

| D8 | ||||

Spindle bore | mm | CDS-BΦ82/CDS-CΦ105 | ||||

Taper of spindle bore |

| CDS-B Metric 90(1:20)/CDS-C Metric 110(1:20) | ||||

Chuck size | mm | CDS-B 中Φ250/CDS-CΦ315 | Φ315 |

| ||

Max. Spindle torque | Nm | 1100 | 1100 | |||

Spindle speed ranges | rpm | CDS-B 26-2000(16 Speeds) / CDS-C 26-1700(16 Speeds) | ||||

Spindle centre height | mm | 250 | 325 | |||

Spindle motor power | kw | 7.5(10 HP) | ||||

Diameter of tailstock quill | mm | Φ75 | ||||

Travel of tailstock quill | mm | 150 | ||||

Taper of tailstock quill |

| No.5 MT | ||||

Longitudinal feed | mm/r | 0.044~1.48 (45 Kinds) ; *0.044~0.148 in/rpm (45 Kinds) | ||||

Cross feed | mm/r | 0.022~0.74 (45 Kinds) ; *0.031~ 0.092in/rpm (45 Kinds) | ||||

Metric threads | mm | 0.5~80 (73 Kinds *53 Kinds) | ||||

Modular threads | mm | 0.5~40 (45 Kinds *66 Kinds) | ||||

Inch threads | TP | 7/16~80(47 Kinds *47 Kinds) | ||||

Diametral pitch threads | DP | 7/8~160 (47 Kinds *48 Kinds) | ||||

Max. tool shank size | mm | 25X25 | ||||

Travel of top slide | mm | 150 | ||||

Swivel angle of top slide | ° | 士45° | ||||

Max. Travel of Tool post | X-axis | mm | 315 | 340 | ||

Z-axis | mm | 950/1450/1950/2950 | ||||

Machine dimensions(L×W×H) | mm | 2930×1223×1295(1000) | 2930×1223×1370(1000) | |||

3430×1223×1295(1500) | 3430×1223×1370(1500) | |||||

3930×1223×1295(2000) | 3930×1223×1370(2000) | |||||

4930×1223×1295(3000) | 4930×1223×1370(3000) | |||||

Machine weight | kg | 2170/2420/2620/3120 | 2500/2700/2900/3400 | |||

Standard accessories:

- 3-Jaw chuck.

- Rear splash guard.

- Tool post guard.

- Fixed center of tailstock.

- 4-way tool post.

- Chuck guard.

- Foot brake.

- Standard toolkit & Oil gun.

Optional accessories:

- 4-Jaw chuck.

- Spindle center and center sleeve.

- Face plate.

- Thread dial.

- Electromagnetic brake.

- 11Kw spindle motor.

- Stead rest &Follow rest

- Drive Plate.

- Large-sized Steady rest&Follow rest.

- DRO.

- Carriage stop.

- Quick-change tool post.

- Live center of tailstock.

- Electromagnetic clutch.

- Taper-turning attachment.

- Anti-vibration/Adjustable pads.

- Gear for special thread(Metric machine).

For customised and optional accessories and parameters of large-scale conventional lathe CDS series, please contact us for more information.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com