PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

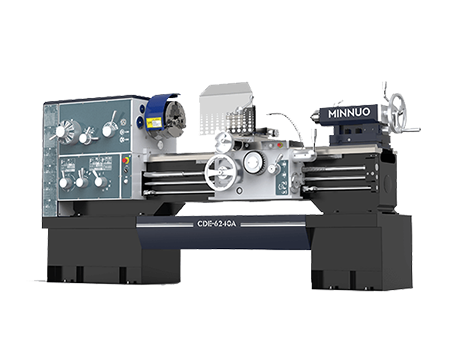

General Lathe CDE-A Series

General lathe CDE-A series is a horizontal lathe suitable for small batch production workshop and mechanical maintenance workshop.CDE-A adopts the popular right-angle plane shape in appearance, and the front and rear legs are wide. The bed guideway is surface high-frequency quenching and grinding processed with quenching hardness of G50. the gears of the headstock box are high-frequency quenching and precision grinding processed at the teeth, and the gear precision can reach grade 7. The dimensional accuracy of the parts processed on this machine can reach IT7 grade, and the surface roughness can reach Ra1.6 grade.

- Maximum workpiece rotation diameter on the bed: Φ400mm(16”)/Φ500mm(20”)/Φ660mm(26”)

- Maximum workpiece turning diameter on the tool holder: 220mm(8 3/5”)/290mm(11 3/8”)/430mm(17”)

- Maximum workpiece length: 750mm(30")/1000mm(40")/1500mm(60")/2000mm(80")/3000mm(120")

Model | CDE6140A | CDE6240A | CDE6150A | CDE6250A | CDE6166A | CDE6266A |

Maximum workpiece rotation diameter on the bed | Φ400mm(16”) | Φ500mm(20”) | Φ660mm(26”) | |||

Maximum workpiece turning diameter on the tool holder | 220mm(8 3/5”) | 290mm(11 3/8”) | 430mm(17”) | |||

Maximum workpiece diameter in the saddle |

| 700mm(27 1/2”) |

| 760mm(30”) |

| 910mm(35″) |

Maximum workpiece length | 750mm(30″)/1000mm(40″)/1500mm(60″)/2000mm(80″)/3000mm(120″) | |||||

Spindle head form | C6 | |||||

Main shaft hole diameter | Φ52mm(maximum rod diameter allowed through Φ50mm) | |||||

Taper of front end of main shaft hole | Morse taper No. 6 | |||||

Spindle speed series | 22 | |||||

Maximum spindle torque | 1586(Nm) | |||||

Spindle speed range | 11-1400 rpm | |||||

Distance from spindle center to Daoxian supporting surface | 27mm(11/16”) | |||||

The maximum size of the tool bar | 25x25mm(1”x1″) | |||||

Maximum transverse travel of the tool holder | 348mm(136/8”) | 373mm(145/8”) | ||||

Maximum longitudinal travel of the tool holder | 700mm(28”)/950mm(38”)/1450mm(57”)/1950mm(77”)/2950mm(116 ”) | |||||

Tail seat sleeve diameter | 75mm(25/16”) | |||||

Tailstock sleeve stroke | 150mm(6”) | |||||

Tail seat sleeve taper | Morse taper No. 5 | |||||

Features

- Configured according to different needs of users. The left and right handwheel skateboard boxes are available in metric, imperial, and metric/english control.

- The spindle box of the machine tool adopts mechanical friction plate clutch, which can realise the speed change, stop and direction change of the spindle without changing the speed of the motor and stopping the motor.

- The sliding plate box of the machine tool is equipped with a fast moving device and an overload safety protection device; the longitudinal and transverse cross manipulation handle and the opening and closing nut handles.

- The feed box of the machine can turn metric, imperial, modulus and diameter threads without changing the hanging wheel.

- Various combinations of metric machine tools, imperial machine tools and left hand wheel slide boxes are available;

- The spindle bore diameter of this series of machine tools is 52mm.

- The spindle head of the machine is C6;

- The power of the main motor of this series of machine tools is 7.5kW/50Hz (5.5Kw/60Hz); special order 5.5kW/50Hz2.10 machine tool headstock box, feed box with oil pump forced lubrication;

Applications

- General lathe CDE-A series can be used for turning bore and end face of cylindrical parts, and drilling and reaming, processing all kinds of metric threads, imperial threads, modulus and diameter pitch, and also processing pitch threads by special order from users.

Standard accessories:

- Three-jaw chucks

- Machine Lights

- Standard tools

- Opening and closing nuts and lateral movement nuts made of tin-bronze

- Y series main motor.

- Cooling unit.

For customised and optional accessories and parameters of general lathe CDE-A series, please contact us for more information.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com