PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

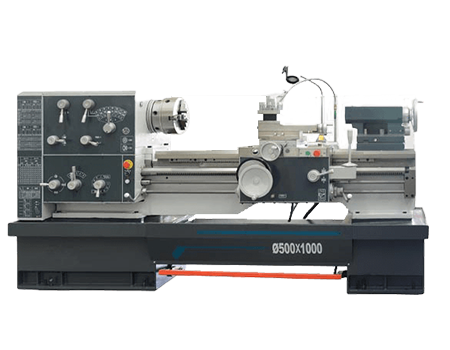

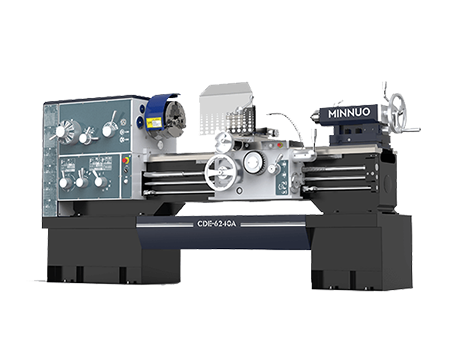

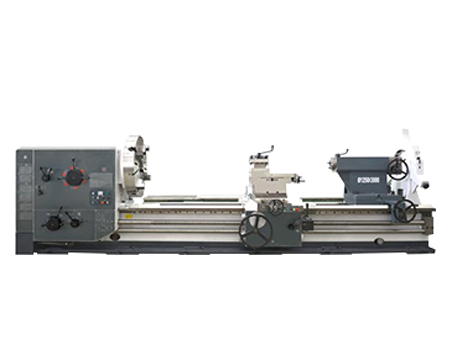

Large-scale Conventional Lathe CW-M Series

The CW-M series large-scale conventional lathe features a mature structure, high power, strong rigidity, and a wide range of spindle speed adjustments. It is suitable for heavy-duty or high-speed cutting, capable of completing various turning operations on shafts and disc-shaped parts, including inner and outer cylindrical surfaces, tapered surfaces, end faces, grooving, chamfering, drilling, tapping, and more. It can also handle commonly used metric threads, imperial threads, module threads, and pitch threads. When equipped with a taper attachment, it can handle commonly used taper threads, and for special threads, consultation is recommended. The compound movement of the longitudinal feed and the tool holder feed allows for the machining of long tapers, while the tool holder can be maneuvered for short tapers. This lathe demonstrates its superiority in machining large and complex parts.

- Max.Swing diameter over bed: Φ1000/Φ1250/Φ1400/Φ1600

- Max.Swing diameter over cross slide: Φ630/Φ880/Φ1030/Φ1230

- Max. workpiece length: 1500/3000/4000/5000/6000/8000

Features

- Strong power: standard main motor power is 22kW, special order 30kW is available.

- Integrated bed, integrated head box: high-quality design and manufacturing technology to provide high rigidity and high precision retention of the equipment.

- Bed body is treated by aging, and the guideway is hardened by high frequency: it makes the service life of the machine longer.

- Bed guideway is precision ground: overall casting, machining and grinding can ensure high precision on the whole length of the guideway.

Key technical indicators:

- High-strength cast iron bed.

- Bed guide rails designed with a combination of V-shaped and flat guide layouts.

- High-rigidity mechanical tool post.

- Capable of machining commonly used metric, imperial, module, and pitch threads.

Specification | Unit | CW61100M | CW61125M | CW61140M | CW61160M |

Max.Swing diameter over bed | mm | Φ1000 | Φ1250 | Φ1400 | Φ1600 |

Max.Swing diameter over cross slide | mm | Φ630 | Φ880 | Φ1030 | Φ1230 |

Max. workpiece length | mm | 1500/3000/4000/5000/6000/8000 | |||

Max.cutting length | mm | 1300/2800/3800/4800/5800/7800 | |||

Max workpiece weight | kg | 6000(Opt:8000 10000) | |||

Bed guideway width | mm | 755 | |||

Spindle nose |

| A2-15 | |||

Spindle bore | mm | Φ130 | |||

Chuck size | mm | Φ1000 | Φ1000 | Φ1250 | Φ1600 |

Taper of spindle bore |

| Metric 140(1:20)(With No.6MT Reducing sleeve) | |||

Max. Spindle torque | Nm | 10.5 kNm (22kW) Opt:12.5kNm (30 kW) | |||

Spindle speed ranges | rpm | 3.15-315(21 Speeds) (Reversal 4.5 ~ 390 12Speeds) | |||

Spindle centre height | mm | 500 | 625 | 700 | 800 |

Spindle motor power | kw | 22 0pt:30 | |||

Diameter of tailstock quill | mm | Φ160 (Max. workpiece weight 6T) | |||

Opt: Φ200 Max. workpiece weight 8T | |||||

Φ240 Max. workpiece weight 10T | |||||

Travel of tailstock quill | mm | 300 | |||

Taper of tailstock quill | mm | Metric 80(With No.6MT Reducing sleeve) | |||

Opt:No.6 MT (Φ200&240) | |||||

Longitudinal feed | mm/r | 0.1~12 (56 Kinds); * 0.0032 ~ 0.40 in/rpm (56 Kinds) | |||

Cross feed | mm/r | 0.05~6(56 Kinds); * 0.0016 ~ 0.20 in/rpm (56 Kinds) | |||

Metric threads | mm | 1~120 (52 Kinds); *1~120 (52 Kinds) | |||

Modular threads | mm | 0.5~60(46 Kinds); * 0.5~60 (46 Kinds) | |||

Inch threads | TPI | 1/4~30 (43 Kinds); * 1/4~30 (43 Kinds) | |||

Diametral pitch threads | DP | 1/2~60(49 Kinds); * 1/2~60 (49 Kinds) | |||

Tool shank size | mm | 45X45 | |||

Travel of top slide | mm | 300 | |||

Machine dimensions(L×W×H) | mm | 4450×1855×1890(1500) | 4450×1955×2015(1500) | 4450×2010×2165(1500) | 4450×2110×2355(1500) |

5950×1855×1890(3000) | 5950×1955×2015(3000) | 5950×2010×2165(3000) | 5950×2110×2355(3000) | ||

6950×1855×1890(4000) | 6950×1955×2015(4000) | 6950×2010×2165(4000) | 6950×2110×2355(4000) | ||

7950×1855×1890(5000) | 7950×1955×2015(5000) | 7950×2010×2165(5000) | 7950×2110×2355(5000) | ||

8950×1855×1890(6000) | 8950×1955×2015(6000) | 8950×2010×2165(6000) | 8950×2110×2355(6000) | ||

10950×1855×1890(8000) | 10950×1955×2015(8000) | 10950×2010×2165(8000) | 10950×2110×2355(8000) | ||

Machine weight | kg | 9650/11000/11900/ | 10650/12000/12900/ | 11350/12700/13600/ | 12050/13400/14300/ |

12800/13700/15500 | 13800/14700/16500 | 14500/15400/17200 | 15200/16100/17900 | ||

Standard accessories:

- 4-Jaw chuck.

- Live&fixed center of tailstock.

- Tool post guard.

- Anchor bolt.

- 4-way tool post.

- Spindle center and center sleeve.

- Chuck quard.

- Standard toolkit & Oil gun.

Optional accessories:

- Thread dial.

- 30kW spindle motor.

- Large-sized steady rest.

- Heady duty tailstock.

- Anti-vibration/Adiustable pads.

- Quick-change tool post.

- DRO.

- Electrical tailstock.

- Roller device.

- Steady rest & Follow rest.

For customised and optional accessories and parameters of large-scale conventional lathe CW-M series, please contact us for more information.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com