PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

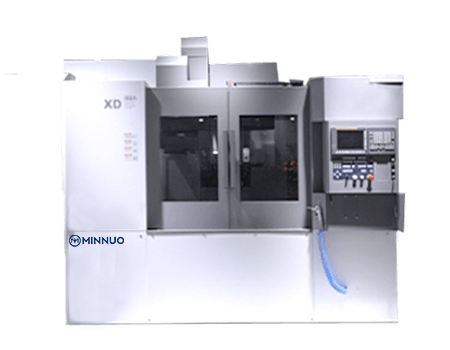

+Machining centers

+Lathe Machine

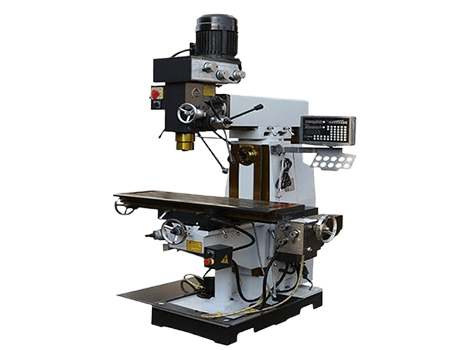

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

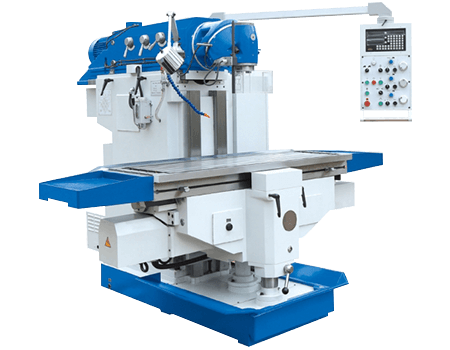

Manual Universal Milling Ram Milling Machine X5750 Series

Manual universal milling ram milling machine X5750 series, the use of advanced guide rail paste molding process, the bonding surface are after manual shovel scraping process, the appearance of the user experience is very good. The whole machine adopts a gear structure with a wide range of variable speed, which can meet both high speed finishing and low speed heavy cutting.

- Table size: 500×2000mm

- T-slots(NO./width/pitch): 5/18/80mm

- Table travel (X/Y/Z): 1400/700/500mm

Specification | Units | X715 | X716 |

Spindle hole taper |

| 7:24 ISO 50 | |

Spindle speed range | r/ min | two-stage stepless 6-300,30-1500 | |

Distance between spindle axis and column guideway | mm | 610 | 8-660 |

Distance between spindle nose and table surface(V) | mm | 10-650 | 10-700 |

Distance between spindle axis and table surface(H) | mm | 8-660 | |

Table size | mm | 2100*500 | 2500*600 |

T slots | mm | 4/20/100 | 5/20/100 |

Table travel-X | mm | 1500 | 1800 |

Table travel-Y | mm | 650 | 700 |

Table feed-X/Y | mm/min | 2.5-3000 | |

Table feed-Z | mm/ min | 2.5-2500 | |

Table rapid feed X/Y/Z | mm/ min | 6000/6000/3000 | |

Main motor power | kw | 11 | |

Torque of X/Y/Z axis AC serve motor | Nm | 18/23/18 | |

Cooling pump motor power | W | 90 | |

Overall size | mm | 3220*2420*2800 | 4380*2520*2800 |

Net weight | kg | 7300 | 9000 |

Features

- The main basic parts such as base, slide, table, column, spindle box, etc. are made of HT300 cast iron and processed by artificial aging, which makes the machine tool stable for long-term use and provides a guarantee for the stability of machine tool performance.

- The overall structure is bed-type structure, the milling head is driven by high-power, high-precision synchronous belt, featuring high transmission precision and low noise.

- The spindle adopts standard ISO50 spindle, which is characterized by high rigidity and convenient speed regulation.

- X, Y, Z three-direction feeding are adopted high precision, high strength ball screws, servo motor drive, the positioning accuracy of the machine is accurate. The guide rail and ball screw adopt protection device, the screw and the guide rail are clean, the machine tool transmission and running accuracy.

- The operating system of the machine is suspended on the upper right side of the machine through the support arm, which is in line with the principle of ergonomics and easy to operate; the operation panel is designed with visualized symbols, which is simple and intuitive.

Applications

- Conventional bed type milling machine has many functions such as milling, drilling, tapping, reaming and reaming etc. It is the processing equipment for machinery, electronics, instrumentation, molds, automotive and other industries.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com