PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

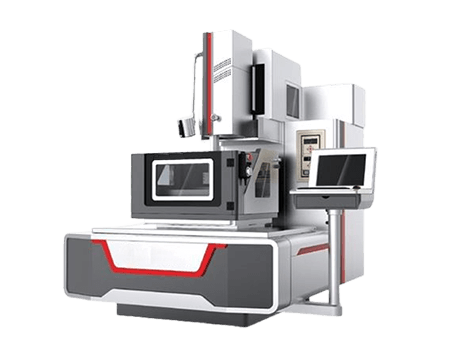

New Type of Medium Speed Wire EDM DK77HZ Series

The DK77HZ Series is a high-precision, medium-speed wire EDM machine with a robust T-type structure for stability and load-bearing. It features 5-axis CNC control for 4-axis linkage cutting, utilizing high-strength construction and precision components like Taiwan ball screws for accuracy. The machine offers quick Z-axis movement, an innovative oil groove design, and a double-tension wire mechanism to maintain consistent wire tension and reduce breakage. The user-friendly interface and compatibility with various drive control software make it adaptable. Equipped with German and Japanese electrical components and NSK precision bearings, it ensures reliability and efficiency.

- Worktable size: 570*780mm

- X,Y axis travel(X*Y): 450*550mm

- Max. cut thickness Z: 300mm

Specifications | Unit | DK7735HZ | DK7745HZ |

Worktable size | mm | 470*680 | 570*780 |

X,Y axis travel(X*Y) | mm | 350*450 | 450*550 |

Max. cut thickness Z | mm | 300 | 300 |

U,V axis travel | mm | 60*60 | |

Diameter of Mo. wire | mm | Molybdenum wire φ0.12~φ0.18 | |

Wire speed |

| 7-speed adjustable | |

Taper angle/ workpiece thickness | ° / mm | 3°/60mm | |

Process accuracy( vertical) | mm | Multi- cut: 10×10×30 Squire≤0.006 | |

Process roughness | μm | Multi- cut: Ra≤0.8 | |

Motor drive system |

| Option: Servo motor | |

Screw & Guides(X,Y) |

| Precision ball screw/ Linear motion guides | |

Wire tension |

| Precision spring automatic tensioning mechanism | |

Working fluid/ capacity | L | Complex or water-soluble special coolant/66L | |

Power supply |

| AC3-φ380V 2kW | |

Max. table carry | kg | 600 | 800 |

Net weight | kg | 1600 | 1800 |

Dimensions | mm | 1800*1260*2100 | 2022*1460*2100 |

Features

- The machine body structure adopts the T-type main structure of the slow-feeding wire, high rigidity, strong load-bearing capacity.

- The machine tool adopts imported servo motor drive, 5-axis numerical control. 4-axis linkage cutting.

- Y, U, V, Z five-axis servo motors and China Taiwan ball screws. High precision and long service life.

- The taper part adopts high strength structure to ensure the displacement precision and the accuracy of taper cutting.

- Z-axis can be lifted and lowered quickly and memorized to return to the position. The oil groove design is novel and special, and can be lifted automatically.

- The wire walking mechanism adopts the upper and lower double-tension wire constant tension mechanism, so that the tension of the electrode wire is always consistent in the cutting process, reducing the phenomenon of wire breakage.

- Operation with imported electronic hand pulse, can manually adjust the machine position, easy to use.

- The cabinet adopts constant source non-resistive electrical structure, small loss, high speed, continuous cutting 100,000mm2 molybdenum wire loss of ≤ 0.005mm.

- The control system can be compatible with the mainstream drive control software on the market at present, which is convenient for customers to choose all kinds of operation software suitable for themselves.

- The electrical components of the whole machine are imported from Germany, Japan, Taiwan and other brands.

- The main parts of the machine tool bearings are imported from Japan NSK precision grade bearings.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com