PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

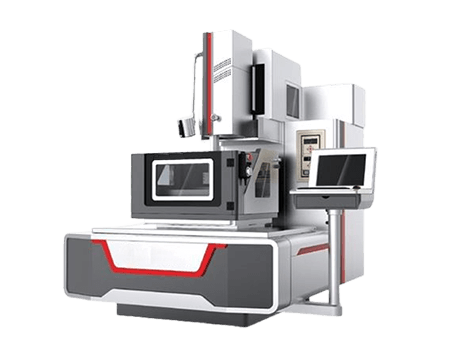

Precision CNC Wire Cutting Machine DK77M Series

The DK77M Series is a precision CNC wire cutting machine with a high rigidity HT300 cast body, 5-axis CNC for complex cutting, and Taiwan Shangyin’s precision components for exceptional accuracy and stability. It achieves high cutting efficiency and ultra-low energy consumption.

- Max. size of workpiece: 780*600mm

- Travel: 550*400mm

- Max. Loading:500kg

Specifications | Unit | DK7725M | DK7732M | DK7740M |

Travel | mm | 320*250 | 400*320 | 550*400 |

Max. cutting thickness | mm | 260 | 260 | 360 |

Max. taper | °/ mm | 10°/60mm | ||

Diameter of Mo. wire | mm | φ0.13~φ0.18 | ||

Wire speed | m/ min | Frequency conversion speed control, the fastest 600m/ min | ||

Max. size of workpiece | mm | 500*400 | 580*500 | 780*600 |

Max. loading | kg | 250 | 350 | 500 |

Filter fineness | mm | 0.005 | ||

Capacity | L | 110 | ||

Manner |

| Differential Pressure Filtration Systems | ||

Max. cutting efficiency | mm²/ min | 200 | ||

Best surface roughness | μm | Ra≤0.8 | ||

Max. machining current | A | 6 | ||

Power supply | V | Three phase four wire 380V | ||

Condition |

| Temperature: 10-35℃ Humidity: 3~75%RH | ||

Power | KVA | 2 | ||

Net weight | kg | 1500 | 1700 | 2200 |

Dimensions | mm | 1730*1650*1900 | 1900*1750*1900 | 2200*1860*2200 |

Features

The DK77M Series offers 5-axis CNC control, pitch and backlash compensation, and compatibility with mainstream software, ensuring efficient, eco-friendly operation for intricate cuts.- The main body of the machine tool is made of high rigidity HT300 resin sand casting, with high rigidity and low vibration.

- The overall structure of the machine tool adopts the main structure of the slow-feeding machine type, with high precision and good stability.

- The screw adopts the high precision double-nut ball screw of Taiwan Shangyin, which has high running precision and ensures the positioning accuracy of the machine tool.

- The guide rail adopts the high-precision linear guide rail of Taiwan’s Shangyin, which has smooth running and high responsiveness.

- The main part of the machine tool adopts 8 NSK imported bearings for high precision and long service life.

- The machine adopts servo motor or hybrid stepping motor drive, 5-axis numerical control, X, Y, U, V four-axis linkage cutting.

- The electrical control part of the machine adopts non-resistive circuit power supply, fast speed and high finish.

- The software control part can compensate the pitch of X, Y, U and V axes, which solves the problem of low precision of large taper and realizes precision cutting of upper and lower shaped parts. The electric control cabinet with hand pulse control, control X, Y, U, V, Z five-axis movement.

- V, Z five-axis movement; real-time display of X, Y, U, V four-axis movement of the coordinate value; can be compatible with the mainstream control system on the market, without the need to add additional servo cards and expansion cards.

Performance

- The main structure and casting process of the slow-speed machine tool.

- highest cutting efficiency≥200mm/min.

- optimum surface roughness ≤ Ra0.8μ m.

- OX, Y. U, V. Z five-axis are used in China Taiwan Shangyin linear guide and high precision grade double-nut ball screws.

- High precision cutting ≤ +2μm.

- Continuous cutting 100,000mm2 molybdenum wire loss ≤ 0.005mm.

- The whole machine is equipped with 8 bearings.

- the whole machine electrical components are imported from Germany, Japan and other brands.

- the control system can be X, Y, U, V four-axis pitch compensation and backlash compensation, and can be compatible with the mainstream drive software on the market, with a handwheel pulse control wire movement cancel the old-fashioned trip, switch control, using encoder direct control, to achieve precision positioning.

- Adopting slow-feeding automatic wire structure, with different processing conditions, automatically adjust the tensioning strength.

- Ultra-low energy consumption, green environmental protection.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com