PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

Electric Servo Press Brake Machine

Full electric power servo bending machine is a kind of high-precision bending equipment with all-electric servo drive, which is characterized by energy saving, high efficiency, easy operation, low maintenance cost and environmental friendly. It is widely used in the precision processing of metal plates, especially suitable for automated production lines that require high bending accuracy.

- Bending Capacity: 65T

- Y-axis Servo Motor: 15KW

- Bending Length: 2500mm

- Column Pitch: 2100

Features

Electric servo bending machine realizes fast response and precise control through electric servo system, which improves productivity, reduces energy consumption, and lowers noise pollution. Its high-precision positioning capability ensures machining quality while reducing maintenance costs and enhancing the safety of the working environment.

- Enhanced Performance: Experience reliable performance with the cutting-edge CNC system EP. Developed on a high-end CNC platform, it incorporates advanced algorithms for precise sheet metal bending and motion control.

- Swift and Accurate Control: Achieve high-speed and high-precision control with our CNC system. Utilizing high-speed acceleration and deceleration algorithms, coupled with trajectory look-ahead capabilities, it meticulously plans motion trajectories, ensuring impeccable bending accuracy even at top speeds. Benefit from its soft motion characteristics, seamlessly integrating speed and precision.

- Energy Efficiency and Eco-friendliness: The CNC system EP is tailored for all-electric servo CNC bending machines, emphasizing energy conservation and environmental protection. Experience significant power savings akin to switching from a conventional air conditioner to an inverter model. Moreover, it eliminates the need for hydraulic oil, thereby eradicating pollution associated with waste hydraulic oil.

- Intelligent Safety Monitoring: Safeguard operators with the intelligent safety light curtain monitoring of CNC system EP. By dynamically assessing the bending process, including safety light curtain signals, workpiece parameters, and linear displacement sensor feedback, it delineates dangerous and safe zones. Unlike conventional safety light curtains, our design prioritizes operator safety without compromising work efficiency.

- Spindle Power Box: Experience unparalleled durability with our spindle power box. Engineered with heavy-duty ball screws, bearings, and a seal protection design, it ensures longevity and resilience against external contaminants like dust.

1.High speed: With a maximum fast forward speed of 30mm/s on the Y axis and a top working speed of 50mm/s.

2.High precision: Featuring a 5um resolution magnetic scale and double-loop control of a high-digit encoder, delivering ±5um repeated positioning accuracy.

3.Consistent Processing: Eliminate the impact of oil temperature changes on bending workpiece consistency.

Specifications | Unit | EP-35T1250 | EP-43T2000 | EP-65T2500 |

Bending Capacity | T | 35 | 43 | 65 |

Y-axis Servo Motor | KW | 6.5 | 7.5 | 15 |

Bending Length | mm | 1250 | 2000 | 2500 |

Column Pitch | mm | 1130 | 1400 | 2100 |

Throat Depth | mm | 410 | 410 | 410 |

Daylight | mm | 470 | 470 | 470 |

Slider Inclination | mm | ±30 | ±30 | ±30 |

Y Rapid Speed | mm/s | 135 | 180 | 160 |

Y Working Speed | mm/s | 50 | 50 | 50 |

Y Retrack Speed | mm/s | 135 | 180 | 165 |

X Rapid Speed | mm/s | 500 | 500 | 500 |

R Rapid Speed | mm/s | 200 | 200 | 200 |

Z1/Z2 Rapid Speed | mm/s | 400 | 400 | 400 |

Y-axis | mm | ±0.01 | ±0.01 | ±0.01 |

X-axis | mm | ±0.02 | ±0.02 | ±0.02 |

R-axis | mm | ±0.1 | ±0.1 | ±0.1 |

Z1/Z2-axis | mm | ±0.1 | ±0.1 | ±0.1 |

Y Stroke | mm | 200 | 200 | 200 |

X Stroke | mm | 500 | 500 | 500 |

R Stroke | mm | 140 | 140 | 140 |

Z1/Z2 Stroke | mm | 400 | 600 | 900 |

Controller System |

| SL100-P4/6 | SL100-P4/6 | SL100-P4/6 |

Installed capacity | kVA | 15 | 15 | 25 |

Dimension | mm | 1475x1358x2439 | 2020x1388x2439 | 2520x1700x2664 |

Weight | kg | 3000 | 3300 | 5100 |

Electric Servo Press Brake Machine

- Y1/2 adopts grating scale or magnetic scale feedback full-closed loop control mode, precise positioning control, repeat positioning accuracy of ±5μm!

- Intelligent safety light curtain monitoring ensures the safety of operators,and has authorized patents, unique!

- Smart tool load monitoring ensures tool safety

- Five-wire touch screen, high reliability and service life of more than 10million times, the operation process is simple and fast.The bending pressure is automatically calculated, and the alarm prompts when the pressure exceeds the limit range.

- The "direct" calculation function of the back gauge position: According to the relative size and plastic deformation of the sheet metal. The back gauge position is directly calculated according to the neutral layer

- Angle intelligent compensation function: According to the sheet metal process parameters such as sheet metal material characteristics, die size, material thickness, bending angle, etc, combined with the angle calculation model of the CNC system, any sheet metal only needs one trial bending and can be automatically corrected according to the angle deviation. Can be officially produced.

- Arc continuous bending function.

- Die parameter library. establish a mold parameter library for customers, which is convenient for customers to quickly call parameters for sheet metal bending.

- Password protection function.

Electric Servo Press Brake Machine

Electricity consumption comparison

40 Ton Full Electric Servo Bending Machine | VS. | Commonly Used 40Tons Hydraulic Bending Machine |

About 1KW | Average Power | About 4.5KW |

3000 Hours | 1 Year Working Time | 3000 Hours |

3000 Degrees | 1 Year Power Consumption | 13500 Degrees |

Note: One year can save electricity: 13500-3000=10500 degrees; five years can save

electricity: 52500 degrees! If there is a lack of electricity at your end, this is a great choice, so hurry up and contact our engineers to get a discounted price!

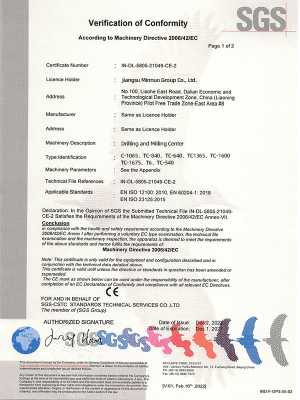

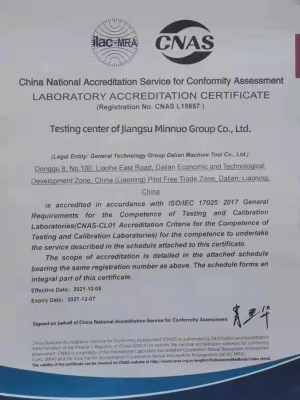

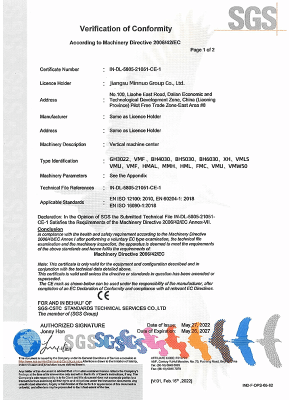

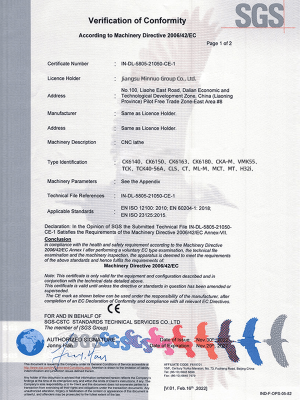

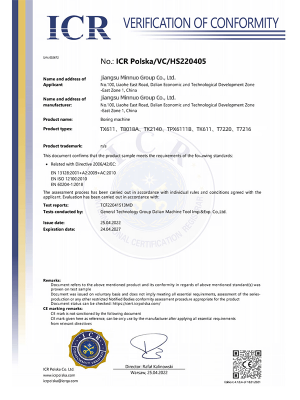

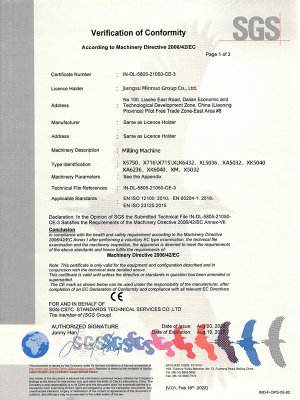

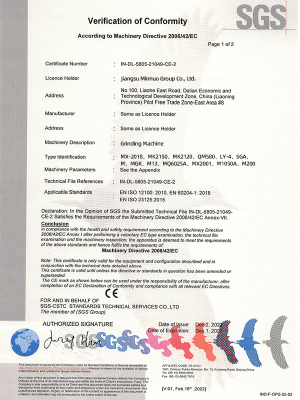

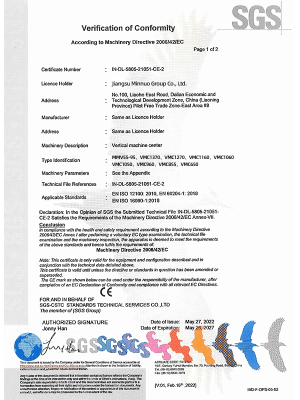

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com