PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

High Precision Classic Slant-bed CNC Lathe MCT Series

Slant-bed CNC lathe MCT series is a two-axis linkage, semi-closed-loop slant-bed CNC lathe, the host bed adopts integral casting molding, ladder-type guideway distribution, the overall structure of the 45 ° inclined layout, with high rigidity, the control system adopts the GSK CNC, FANUC 0i-TF, Siemens, HNC and other systems and AC servo drive, can be a variety of shafts and discs commissioned for various types of parts turning process.

- Max.swing diameter over machine bed : 1250/1600/2000/2500/3000mm

- Max.swing diameter over cutting tool carriage: 800/1250/1600/2000/2500mm

- Max.work-piece weight: 2/3T

| Specification | Unit | MCT40H |

| Max. swing over bed | mm | 500 |

| Max. turning length | mm | 450 |

| Max. turning diameter(shaft/disc) | mm | 260/300 |

| Type of guideway | Linear | |

| Angle of bed | 45° | |

| Chuck size | 8” | |

| Spindle nose | A2-6 | |

| Spindle bore | mm | 62 |

| Bar capacity | mm | 52 |

| Spindle speeds | rpm | 45 – 4500 |

| Spindle motor | rpm | November 15 |

| Spindle motor torque | Nm | 93/127 |

| Number of tool stations | 12 | |

| Indexing time | s | 0.36/1.01 |

| (with/without adjacent tool) | ||

| Shank size for OD tool | mm | 25×25 |

| Shank size for ID tool | mm | 32 |

| Live tool motor | Kw | 3.7/5.5 |

| Live tool max. speed | rpm | 4000 |

| Live tool max.drilling capability | mm*mm/u | 14*0.15 |

| Live tool max.tapping capability | mm*mm | M10x1.5; M24x1 |

| Live tool max.milling capability | mm*mm*mm/min | 20*14*40 |

| (dia.*depth*speed) | ||

| X/Z axis travel | mm | 165/500 |

| X axis rapid travel | m/min | 20 |

| Z axis rapid travel | m/min | 24 |

| Feedrate | mm/min | 0~9000 |

| Quill diameter | mm | 80 |

| Quill inside taper | MT.4 | |

| Quill travel | mm | 130 |

| Tailstock travel | mm | 460 |

| Positioning | mm | X/Z:0.008/0.008 |

| Repeatability | mm | X/Z:0.004/0.004 |

| Machine size(side chip conveyor) | mm | 3900*1800*1850 |

| Net weight | kg | 4000 |

Features

Electric servo bending machine realizes fast response and precise control through electric servo system, which improves productivity, reduces energy consumption, and lowers noise pollution. Its high-precision positioning capability ensures machining quality while reducing maintenance costs and enhancing the safety of the working environment.

- The design of the machine tool is analyzed by finite element, and its structure is reasonable and the ribs are arranged appropriately, so that it has sufficiently high static and dynamic rigidity to withstand high cutting torque and good precision retention. The main part of the machine tool is made of resin sand casting, and the bed is a monolithic casting. The machine tool is characterized by high rigidity, small thermal deformation, low temperature rise of the spindle, and small vibration.

- The main structural parts of the machine tool, such as bed, spindle box, bed saddle, tailstock and other key parts, are processed by advanced equipment such as pentahedral machining center. High-precision machining equipment ensures high machining accuracy and stable quality of the machine parts, and the technical performance of the machine is guaranteed.

- Advanced design concepts, optimized structural design and technological measures ensure that the machine tool has high machining accuracy and long-term accuracy retention.

- The machine tool adopts modular design, which can provide various configurations according to the diversified requirements of users, such as rotary tailstock, pneumatic door, pneumatic skylight, high-pressure water discharge from the spindle center and so on.

- The main transmission system of the machine tool adopts AC servo motor with high efficiency parallel V-belt to directly drive the spindle. Avoid the noise problem caused by the gear box transmission chain.

- The machine tool is fully enclosed and protected, completely avoiding the leakage of iron chips and coolant, and the various limit protections of the organization together with the self-diagnostic prompts and warnings of the system can ensure that the machine tool can work continuously without stopping, which is especially suitable for 24-hour working system production lines.

Applications

- Slant-bed CNC lathe MT series can be used for machining shaft parts and disk parts, and the parts can be automatically completed multi-process turning, boring, drilling, expanding, reaming, tapping and other machining by one clamping.

- It is suitable for automobile, mold, electronics, light industry and other industries.

Standard accessories:

- Linear guideway

- Hydraulic8-position turret

- Non through-hole hydraulic chuck

- Hydraulic tailstock

- Scrap collection box

- Heat exchanger

- Alarm stack light

- Semi-closed-loop measuring device

Optional accessories:

- Oversized spindle12

- Hydraulic 12-position turret

- Through-hole hydraulic chuck and cylinder

- Air conditioner

- Rotary mandrel tailstock

- Chain-type chip conveyor

- Parts catcher

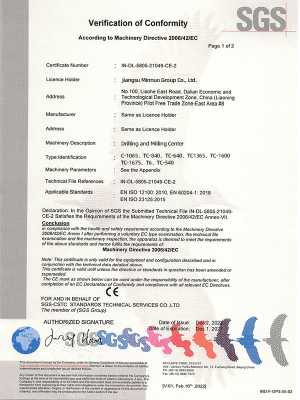

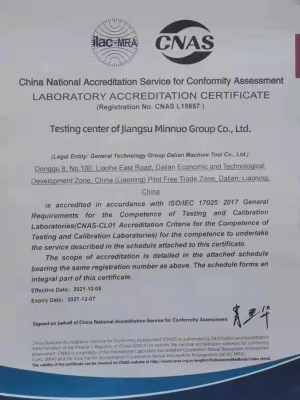

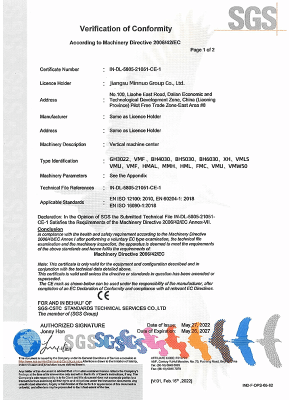

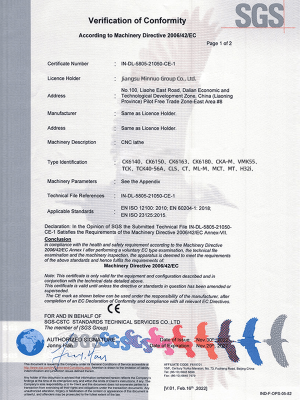

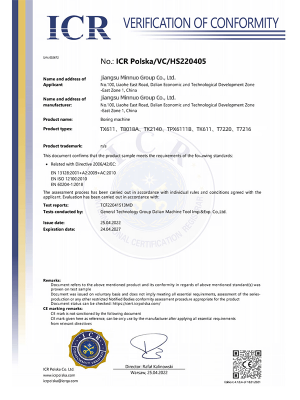

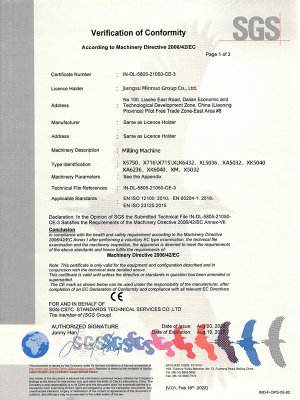

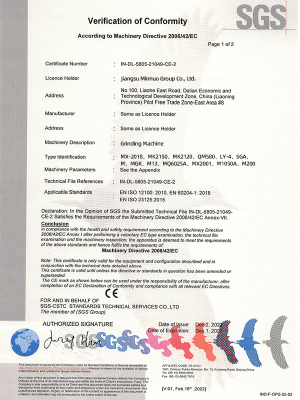

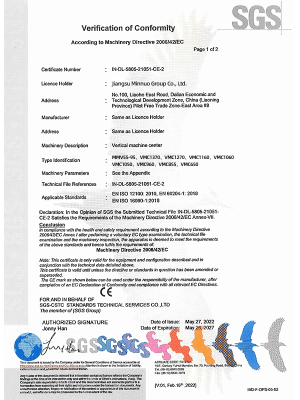

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com