PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

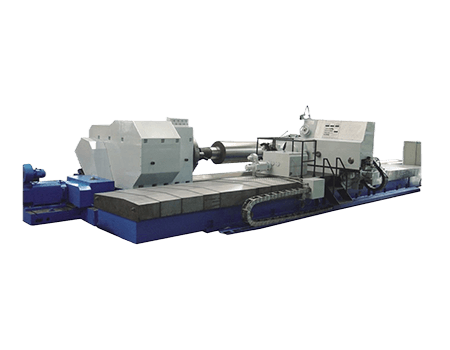

Large Machining Range Slant-bed CNC Lathe ML-M Series

Slant-bed CNC lathe ML-M series is a CNC lathe developed and produced by our company with international advanced level. The main machine bed adopts integral casting molding, and the bed guideway is 45°inclined layout, which has high rigidity. It can be used for turning, drilling and milling of shaft parts and disk parts. The machine tool is widely used in automobile parts, molds, bearings, coal machinery manufacturing and other industries.

- Max. swing diameter over bed: Φ520~Φ900mm

- Max. turning diameter(Shaft/Disc): Φ310/Φ520~Φ660/Φ760mm

- Max .turning length: 950/1450/1950/2950mm

| Specification | Unit | ML-25M | ML-25MH | ML-32M | ML-32MH | ML-40M | ML-40MH |

| Max. swing diameter over bed | mm | Φ520 | Φ680 | Φ900 | |||

| Max. turning diameter(Shaft/Disc) | mm | Φ310/Φ520 | Φ310/Φ500 | Φ440/Φ630 | Φ440/Φ590 | Φ600/Φ800 | Φ660/Φ760 |

| Max .turning length | mm | 1000/1500 | 1000/1500/2000/3000 | 950/1450/1950/2950 | 1000/1500/2000/3000 | 950/1450/1950/2950 | |

| Guideway type | Box way Opt:Linear guideway(1000) | Box way | Box way | ||||

| Chuck size | inch | 10 | 15 | 15 | |||

| Type of spindle nose | A2-8 | A2-11 | A2-11 | ||||

| Spindle speed range | rpm | 3500 | 2000 | 1500 | |||

| Spindle bore | mm | Φ87 | Φ100 | Φ130 | |||

| Max. bar capacity (Equipped with through-hole hydraulic chuck) | mm | Φ74 | Φ80 | Φ80 | |||

| Spindle motor power | kw | 15/18.5 | 18.5/22 | 22/30 | 22/30 | ||

| Max Cross travel of X axis | mm | 260 | 375 | 435 | |||

| Max Cross travel of Z axis | mm | 1040/1600 | 1020/1520/2020/3020 | 1020/1520/2020/3020 | |||

| Rapid traverse of X/Z axis | m/min | 12/12 Box way 24/16 Linear guideway | 12/16 | 12/16 | |||

| Turret type and tool numbers | 12-position turret Hydraulic | 12-position live tooling turret | 12-position turret Hydraulic | 12-position live tooling turret | 12-position turret Hydraulic | 12-position live tooling turret | |

| Tool shank size | mm | 25X25 | 32X25 | 32X25 | |||

| Indexing time(adjacent/farthest) | s | 0.45/1.45 | 0.94/1.33 | 0.45/2.2 | 0.94/1.33 | 0.45/2.2 | 0.94/1.33 |

| Diameter of tailstock quill | mm | Φ100 | Φ160 | Φ160 | |||

| Tailstock quill stroke | mm | 139 | 180 | 180 | |||

| X(C) axis positioning accuracy | mm | 0.011 | 0.011(44″) | 0.011 | 0.011(44″) | 0.011 | 0.011(44″) |

| Z axis positioning accuracy | mm | 0.018/0.021 | 0.018/0.021 | 0.018/0.021/0.021/0.021 | 0.018/0.021/0.021/0.021 | 0.018/0.021/0.021/0.021 | 0.018/0.021/0.021/0.021 |

| X(C) axis repeatability accuracy | mm | 0.004 | 0.004(18″) | 0.004 | 0.004(18″) | 0.004 | 0.004(18″) |

| Z axis repeatability accuracy | mm | 0.007/0.009 | 0.007/0.009 | 0.007/0.009/0.009/0.009 | 0.007/0.009/0.009/0.009 | 0.007/0.009/0.009/0.009 | 0.007/0.009/0.009/0.009 |

| CNC Controller | FANUC 0i-TF(5) PIus SIEMENS 828D | FANUC 0i-TF(1) PIus SIEMENS 828D | FANUC 0i-TF(1) Plus SIEMENS 828D | FANUC 0i-TF(1) Plus SIEMENS 828D | |||

| Machine dimensions(L×W×H) | mm | 5010×2020×2110(1000) | 5962×2095×2215(1000) 6461×2153×2268(1500) | 5962×2312×2455(1000) 6461×2374×2505(1500) | |||

| Rear chip conveyor | 5200×2020×2110(1500) | 6961×2153×2268(2000) 8349×2376×2383(3000) | 6961×2376×2505(2000) 8349×2599×2618(3000) | ||||

| Machine weight | kg | 7800/8300 | 11000/12000/13000/14500 | 11500/12500/13500/15000 | |||

Features

- High-performance spindle, front and rear ends adopt NSK precision high-speed spindle bearing set with appropriate preload force, together with spanning support as well as box type spindle box, which makes the spindle with high rigidity and high-speed operation capability.

- High rigidity hydraulic turret, turret internal large axial tension, to ensure that the cutter has a high torsional rigidity and repeatable positioning accuracy.

- High precision drive system. The machine tool adopts precision ball screw and linear rolling guide, with high transmission efficiency and good precision maintenance, which makes the machine tool holder move quickly and stably with high positioning accuracy.

Technical Advantages

- For the bed, bed saddle, screw, support and other precision-related parts, carefully optimized structure and machining accuracy, increase the assembly control items, so that the machine’s accuracy and reliability of the various significantly improve the repeatability of the positioning accuracy increased by 30%, the individual performance indicators to reach the standard of precision-grade machine tools.

- The machine tool provides continuous and effective automatic lubrication, automatic chip removal and forced cooling of the guide rail and ball screw, which can ensure the uninterrupted work of the machine tool for a long period of time, with the maximum spindle speed of 4500 r/min, the maximum rapid traverse speed of 24m/min, and the shortest tool change time of neighboring stations is only 0.45s. The combination of the indexes and the reliable operation of the machine tool can make the machine tool machining efficiency increase by more than 10%.

- The machine tool is fully enclosed, completely avoiding the leakage of iron chips and coolant, and the various limit protections of the mechanism, together with the self-diagnostic prompts and warnings of the system, can ensure that the machine tool can work continuously without stopping, which is especially suitable for 24-hour working system production lines.

Applications

- Slant-bed CNC lathe ML-M series can be used for turning, drilling and milling of shaft parts and disk parts. The machine tool is widely used in automobile parts, molds, bearings, coal machinery manufacturing and other industries in the processing of shaft parts, disk parts, parts can be automatically completed by a single clamping multi-process turning, boring, drilling, expanding, reaming and other processing.

Standard accessories:

- Box way

- Servo-driven spindle

- Non through-hole hydraulic chuck

- Hydraulic tailstock

- RH-mounted chain-type chip conveyor

- Heat exchanger

- Alarm stack light

- Semi-closed-loop measuring device

Optional accessories:

- Through-hole hydraulic chuck and cylinder

- Imported Electric servo turret

- Hydraulic steady rest

- Air conditioner

- Rotary mandrel tailstock

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com