PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

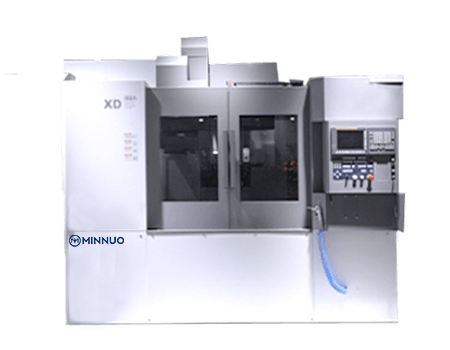

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

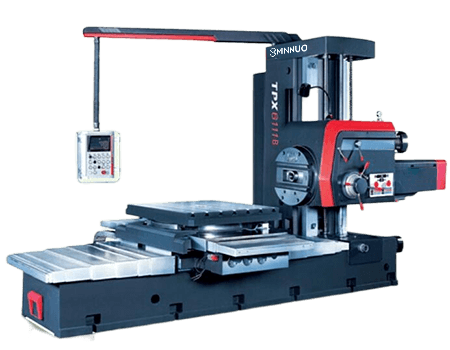

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

High Precision CNC Lathe

High-precision CNC lathe is a new generation of modular design CNC machine tools, support 3 to 5-axis linkage, with HT300 high-strength integral casting bed and secondary simmering heat treatment process, to ensure its high precision and stability; the spindle structure adopts high-precision special bearings, to provide high rigidity and precision, can extend the C-axis function and milling-turning composite capacity, and can be equipped with a hydraulic power chuck or three-jaw self-centering chuck, according to the demand. It can also be equipped with hydraulic power chuck or three-jaw self-centering chuck to meet diversified processing needs.

- Max. swing over bed: φ630~φ1250mm

- Max machining diameter: φ850~φ1250mm

- Max length of workpiece: 1000/1500/2000/3000/4000/5000mm

| Specification | Unit | CNC630 | CNC850 | CNC1000 | CNC1250 | |

| Main specification | Max. swing over bed | mm | φ630 | φ850 | φ1000 | φ1250 |

| Max machining diameter | mm | φ630 | φ850 | φ1000 | φ1250 | |

| Max. swing over carriage | mm | φ430 | φ630 | φ850 | φ1000 | |

| Max length of workpiece | mm | 1000/1500/2000/3000/4000/5000 | ||||

| Max weight of workpiece | kg | 2000 | 4000 | |||

| Spindle | Spindle nose | ISO A2-11 | ISO A2-11 | ISO A2-15 | ISO A2-15 | |

| Diameter of spindle in front bearing | mm | φ160 | φ160 | φ200 | φ200 | |

| Spindle hole | mm | φ95 | φ95 | φ120 | φ120 | |

| Max. speed of spindle | rpm | 2000 | 1500 | 1200 | 1200 | |

| Power of spindle servo motor | kw | 26.5 | 38 | 45 | 45 | |

| Chuck diameter(hydraulic ch uck is optional) | 15 | 18 | 20 | 20 | ||

| Tailstock | Hydraulic programmable tailstock is optional | |||||

| Diameter of tailstock | mm | φ180 | φ180 | φ200 | φ200 | |

| Travel of tailstock | mm | 160 | 160 | 200 | 200 | |

| Taper of tailstock | MT6 | |||||

| Drive unit | Travel of X axis | mm | 315 | 425 | 500 | 625 |

| Travel of Z axis | mm | 1050/1550/2100/3100/4100/5100 | ||||

| Rapid traverse of X axis | m/min | 10( Box guide way)/20( linear guide way) | ||||

| Rapid t raverse of Z axis | m/min | 8( Box guide way)/15( linear guide way) | ||||

| Feed rate of X axis | m/min | 0.001-4000 | ||||

| Feed rate of Z axis | m/min | 0.001-4000 | ||||

| NC horizontal turret | Servo power turret is optional | |||||

| Tool position | 12/8 | 12/8 | 12/8 | 12/8 | ||

| Section of tool shank | mm | 25*25 | 32*32 | 40*40 | 40*40 | |

| Diameter of boring bar | mm | φ32 | φ40 | φ50 | φ50 | |

| Choosing tool at the nearest distance | Yes | |||||

| System configuration | CNC system | SIEMENS 828D or FANUC 0I-TF | ||||

| Servo motor for X axis | 27Nm | 38Nm | ||||

| Servo motor for Z axis | 27Nm | 38Nm | ||||

| Detecting unit | Optional | |||||

| Grating scale | Optional | |||||

| Encoder | Optional | |||||

| Tool setting | Optional | |||||

Features

Electric servo bending machine realizes fast response and precise control through electric servo system, which improves productivity, reduces energy consumption, and lowers noise pollution. Its high-precision positioning capability ensures machining quality while reducing maintenance costs and enhancing the safety of the working environment.

- The whole machine of high-precision CNC lathe adopts modular design and is equipped with 3-axis, 4-axis and 5-axis linkage function.

- The bed is made of high-strength grade HT300 whole 45 degree casting and secondary simmering heat treatment process, which is characterized by high precision and high stability. Can be configured according to user needs linear guide, or inlaid steel guide, ordinary quenching guide different configurations.

- The spindle structure adopts high-precision spindle special bearings, and carry out reasonable grouping and span design, so that the spindle obtains high rigidity and high precision performance.

- C-axis function can be conveniently configured according to the demand to realize milling-turning compound function with power tool holder.

- It can be equipped with hydraulic power chuck and three-jaw self-centering chuck.

Applications

- High precision CNC lathe is mainly used for processing shafts, disks, boxes and other complex curved parts.

- It is widely used in automobile industry, aerospace, machinery manufacturing and shipbuilding.

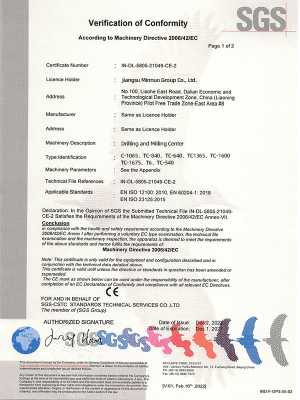

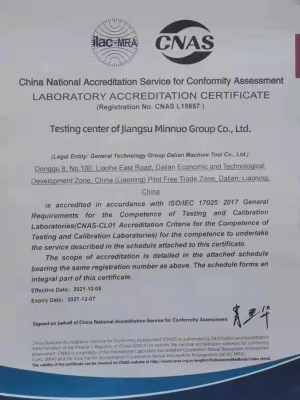

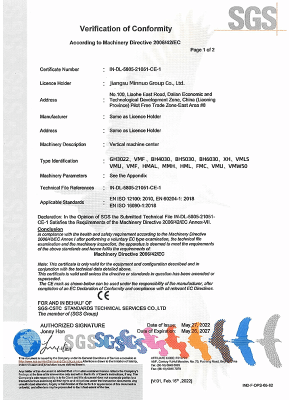

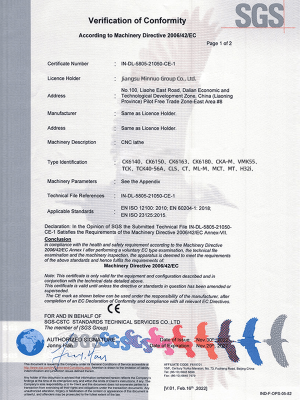

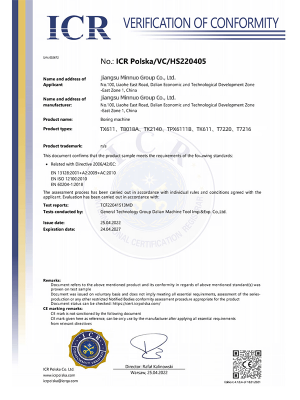

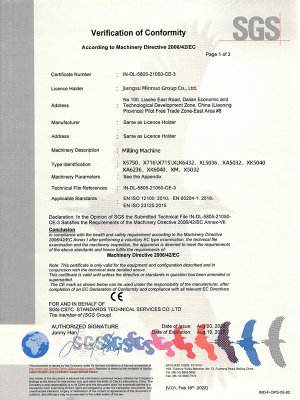

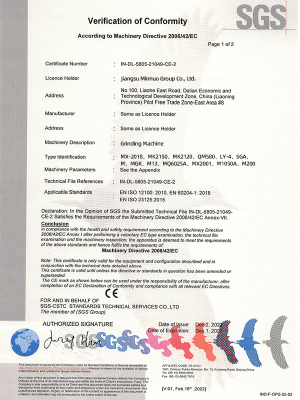

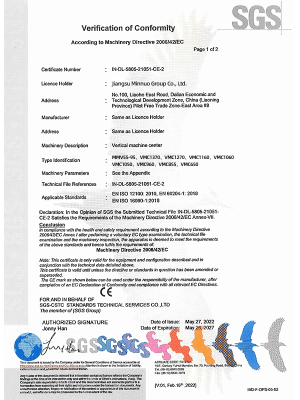

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com