PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

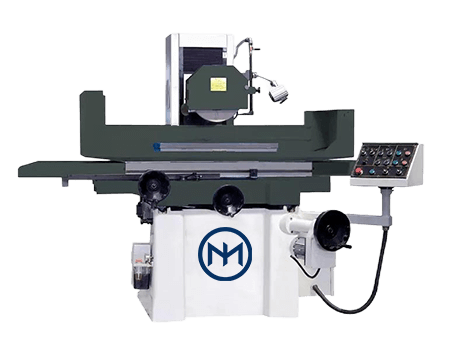

Manual Surface Grinder M Series

Manual Surface Grinding Machine M series adopts cross-drag layout, and three-way feeding is done manually. It mainly grinds the flat surface of the workpiece with the circumference of the grinding wheel, and can also grind the vertical plane of the workpiece with the end face of the grinding wheel. It can grind workpieces made of steel, cast iron, non-ferrous metals and other materials, and is suitable for machining workshop maintenance workshop and tool workshop.

- Table size: 480*200mm

- Max.travel of table: 530*220mm

- T-slot of table: 1*14mm

Specification | Unit | 618A | MG618A | 818A |

Table size(L*W) | mm | 460*180 | 460*180 | 480*200 |

Max.travel of table(L*W) | mm | 500*190 | 500*190 | 530*220 |

T-slot of table(No.*width) | mm | 1*14 | ||

Distance from spindle center to worktable | mm | 335 | 440 | 440 |

Wheel size(OD*Width*ID) | mm | 200*13*31.75 |

| 200*13*31.75 |

Spindle speed(stepless) | r/min | 2850 | ||

Vertical feed handwheel per revolution | mm | 1.25 | ||

Vertical feed handwheel per division | mm | 0.005 | ||

Transverse feed handwheel per revolution | mm | 5 | ||

Transverse feed handwheel per division | mm | 0.02 | ||

Spindle motor | KW | 1.1 | ||

Cooltant motor | KW | 0.04 | ||

Parallelism of machined surface to base surface | mm | 300:0.004 | 300:0.002 | 300:0.004 |

Surface roughness | μm | Ra0.32 | Ra0.16 | Ra0.32 |

Net/Gross weight | kg | 650/750 | 650/750 | 750/850 |

Permanent-magnetic chuck | mm | 400*150 | 400*200 | |

Package dimension(L*W*H) | mm | 1000*1150*1760 |

| 1140*1250*1940 |

Features

- Cross board layout

- High precision sliding screw

- High strength cast iron foundation

- Machine transverse movement adotps saddle moving double V guide rail structure with TEflon soft belt to improve guide positioning accuracy and reduce friction

- Column adopts double wall structure to improve rigidity

- Grinding head adopts high precision rolling bearing spindle set, sleeve mounted, can achieve high precision and high finish grinding

Applications

- Manual surface grinder M series can grind workpieces made of steel, cast iron, non-ferrous metals and other materials, suitable for use in machine shop maintenance workshop and tool shop.

Standard Accessories

- Cooling devices

- Lubrication device

- Grinding wheel chuck

- Grinding wheel balancing shaft

- Electromagnetic chuck

Optional accessories

- Cooling Dust Extraction Unit Paper Belt Filter

- Cooling Magnetic Separator

- Dust suction device

- Grinding wheel balancer

- Y and Z axis digital scale

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com