PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

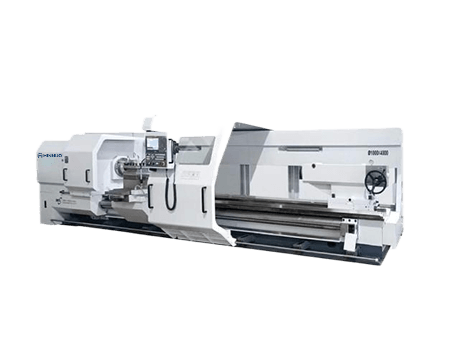

Saddle Moving Surface Grinder SGA Series

Saddle type surface grinder is a kind of surface grinder which adopts cross arm linkage and saddle guide type structure. Its main feature is that the transverse traveling track is guided by the guide rail, and the table is close to the grinding head, which is suitable for medium and small surface grinding and processing as well as curved and difficult-to-machine workpieces. This series machine is divided into AHR and AHD series. The AHR type is driven by ordinary motor in vertical direction, while the AHD type is driven by servo motor in vertical direction, and PLC control can realize automatic grinding.

- Max. longitudinal travel: 1130mm

- Cross travel: 450mm

- Max. distance: 560mm

- Table size: 406*1020mm

| Specification | Unit | SG-2050H/AH | SGA-2550AH | SGA-3063AH | SGA-30100AH | SGA-4080AH | SGA-40100AH | |

| SG-2050AHR | SGA-2550AHR | SGA-3063AHR | SGA-30100AHR | SGA-4080AHR | SGA-40100AHR | |||

| SG-2050AHD | SGA-2550AHD | SGA-3063AHD | SGA-30100AHD | SGA-4080AHD | SGA-40100AHD | |||

| Table size(w×L) | mm | 200×460 | 250×500 | 305×635 | 305×1020 | 406×813 | 406×1020 | |

| Max. longitudinal travel | mm | 510 | 560 | 765 | 1130 | 910 | 1130 | |

| Cross travel | mm | 238 | 275 | 340 | 340 | 450 | 450 | |

| Max. distance from spindle center to table | mm | 450 | 450 | 560 | 560 | 560 | 560 | |

| Magnetic chuck size | mm | 200×460 | 250×500 | 300×600 | 300×1000 | 400×800 | 400×1000 | |

| Speed of table longitudinal movement | m/min | 7~23 | ||||||

| Table transverse movement | Auto feed | mm/min | 0.1~8 | |||||

| Rapid speed | mm/min | 990 | ||||||

| Feed of handwheel | mm/div. | 0.02 | ||||||

| Wheelhead vertical movement | Auto feed | mm/stroke | ——(AH/AHR mode) 0.005/0.01/0.02/0.03/0.04/0.05(Only for AHD model) | |||||

| Rapid speed | mm/min | (AH mode) 460(Only for AHR/AHD model) | ||||||

| Feed of handwheel | mm/div. | 0.005 | ||||||

| Grinding wheel | Speed | rpm | 2850(50Hz)、3450(60Hz) | 1450(50Hz)、1750(60Hz) | ||||

| Size (OD×W×ID) | mm | 200×20×31.75 | 350×40×127 | |||||

| Spindle Motor | kW | 1.5 | 2.2 | 5.5 | ||||

| Hydranlic motor | kW | 1.5 | 0.75 | 2.2 | ||||

| Cooling pump motor | kW | 0.04 | 0.125 | |||||

| Elevating motor | kW | —(AH mode)0.25(AHR mode) 0.5(AHD mode, servo motor) | ||||||

| Cross feed motor | kW | 0.08 | ||||||

| Max. loading capacity of table(include magnetic chuck) | kg | 120 | 180 | 270 | 400 | 500 | 600 | |

| Total rated power | kW | 3 | 3.7 | 9 | ||||

| Height of machine | mm | 1675 | 1890 | |||||

| Floor space (L×W) | mm | 1700×1200 | 2300×1650 | 2900×2200 | 4400×2200 | 3600×2400 | 4400×2400 | |

| Gross weight | kg | 1200 | 1800 | 2600 | 3300 | 3300 | 3700 | |

| Package dimensions(L×W×H) | mm | 1900×1720×2175 | 2000×2100×2175 | 2350×2220×2150 | 2950×2220×2210 | 2850×2270×2180 | 2950×2270×2210 | |

Features

- The machine adopts cross-pallet layout, and the transverse guideway is coated with PTFE soft tape.

- The table moves with a closed hydraulic system, and the front and rear feeds can be manually fed or automatically intermittently fed by a motor-driven screw.

- The up and down movement of the grinding head can be accomplished by using the lifting motor for fast lifting (AHR) or servo motor for fast lifting and automatic feeding (AHD), or manually.

- Adopting high-precision sliding screw and high-strength cast iron base parts, the grinding head spindle adopts precision angular contact rolling bearings, high rigidity sleeve structure, the overall quality of the machine tool is stable, and the operation is smooth.

Applications

- Saddle type moving surface grinding machine can grind workpieces made of steel, cast iron, non-ferrous metals and other materials.

- It is widely used in medical equipment, electronic industry, machinery manufacturing, military and aerospace industry, automobile and motorcycle parts and mold industry, etc.

Standard Accessories

- Grinding Wheel

- Electromagnetic chuck

- Hydraulic station

- Cooling unit

- Lubrication device

- Grinding wheel chuck

- Grinding wheel balancing shaft

Optional Accessories

- Manual Parallel Dresser

- Wheel Balancer

- Dust suction device

- Cooling magnetic separator

- Magnetic Roller Belt Filter

- Digital display device

- Electro-permanent magnetic suction cups

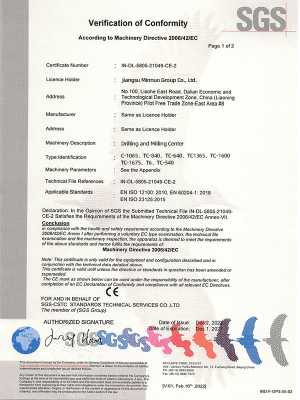

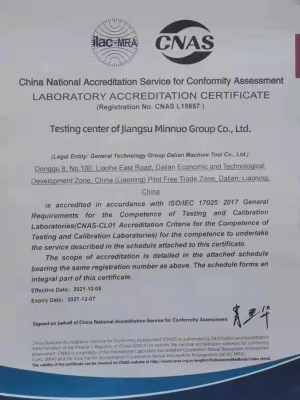

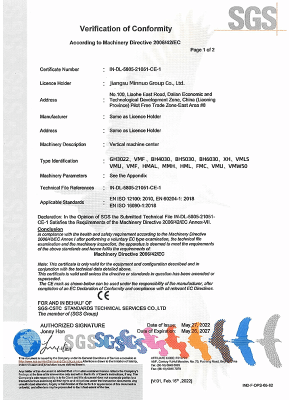

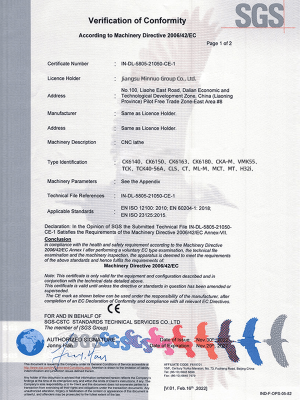

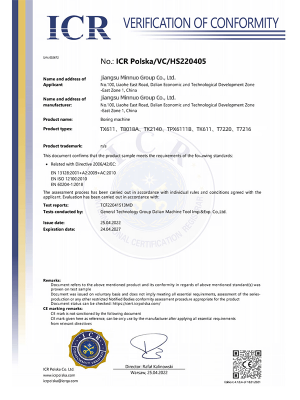

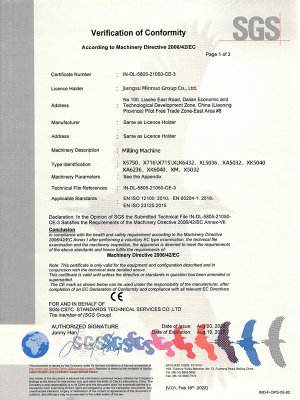

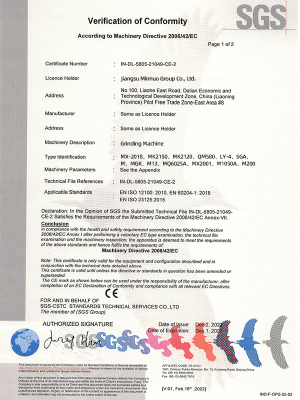

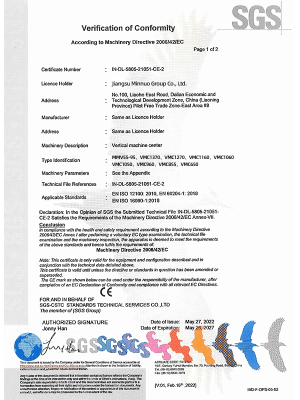

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com